A kind of water-based color paint suitable for wet spray wet process and its application

A color paint, water-based technology, applied in coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problems that it is difficult to achieve the appearance and color effect, and the risk of aggravating the disadvantages of water-based color paint film, to achieve excellent Stability, enhanced color effects, good workability and appearance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

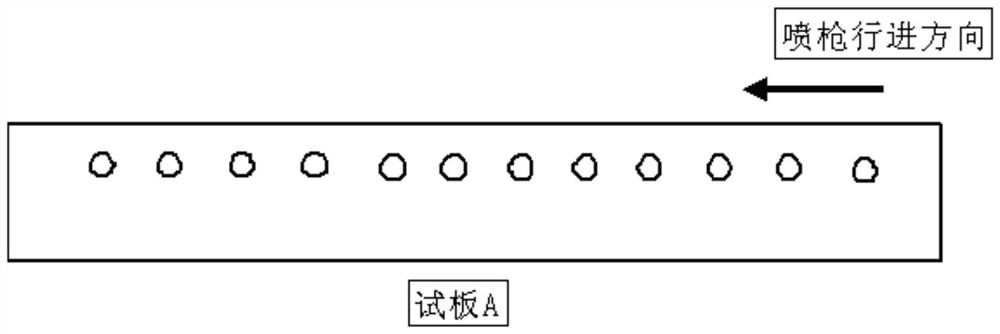

Image

Examples

manufacture example

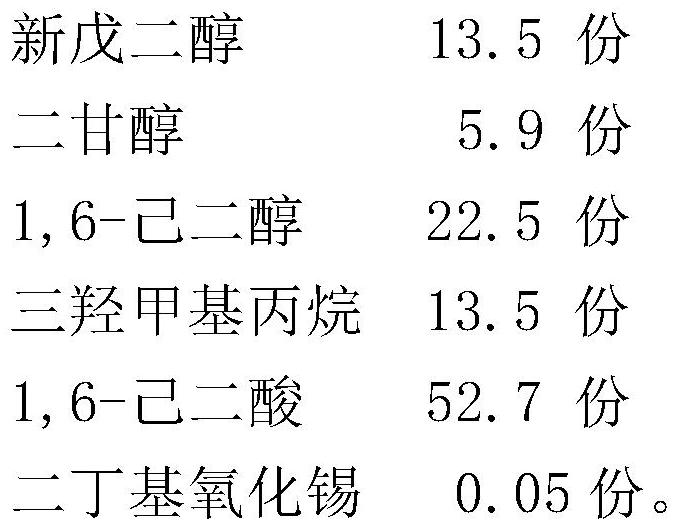

[0068] (1) Manufacture of polyester polyol

[0069] In the reaction vessel equipped with a reflux cooling device with a reaction water outlet, a thermometer, a stirring device and a nitrogen inlet pipe, put the following raw materials into:

[0070]

[0071] Heat up to 120°C and heat up to 160°C with continuous stirring after the raw materials are dissolved. After keeping at 160°C for 1 hour, the temperature was raised to 230°C for 5 hours. Test the acid value at regular intervals at 230°C until the acid value of the resin reaches 1mgKOH / g. Then cool to below 80°C to obtain polyester polyol A with an acid value of 1 mg KOH / g, a hydroxyl value of 129 mg KOH / g, and a number average molecular weight of about 1000.

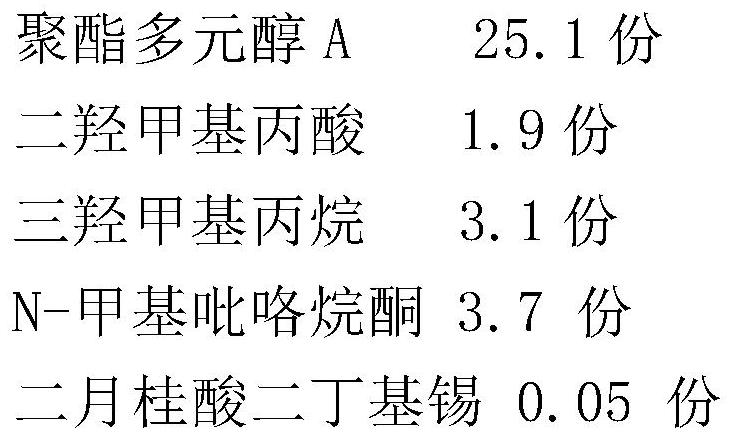

[0072] (2) Synthesis of polyurethane

[0073] In the reaction vessel equipped with a reflux cooling device with a reaction water outlet, a thermometer, a stirring device and a nitrogen gas introduction pipe, put the following raw materials.

[0074]

[0075]...

manufacture example 1

[0110] The preparation process of water-based paint comprises in manufacturing example 1:

[0111] The first step is to add ALUMINUM PASTE LX-318S and A-903K-SP to the auxiliary cylinder a, then add ethylene glycol phenoxyethanol and phenoxyethanol to dissolve, and stir for 10 minutes; then add ACS-1016, Surfynol- 440, BYK-345, DISPERBYK-182, stirred for 20min to obtain the mixture.

[0112] In the second step, add water-based polyurethane A, NP-6100, and CYMEL 250 to the main tank b in turn, and stir for 30 minutes; then add CYMEL 370N, BYK-011 in turn, and stir for 15 minutes, and adjust the pH value with 10% aqueous solution of dimethylethanolamine Between 7.8-8.5.

[0113] In the third step, add acrylic emulsion B and ADEKANOL UH-814N to the main cylinder b in turn, and stir for 30 minutes; then add ACW-1011 and AR-2000(T)G314 / BF-21PASTE UDP in turn, and stir for 20 minutes.

[0114] The fourth step is to add the mixture in the auxiliary vat a to the main vat b while sti...

manufacture example 2

[0118] Preparation method is the same as manufacture example 1. The difference is that AQUACER 507 wax emulsion is added in the fifth step.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com