Cell culture chamber and culture vessel with same

A cell culture and top plate technology, applied in the field of bioengineering, can solve the problems of vibration affecting cell growth and easily destroying cell culture chambers, etc., and achieve the effects of being beneficial to cell growth, improving material exchange, and protecting structural integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The cell culture chamber is suitable for adherent culture or suspension culture; including but not limited to monolayer static culture in culture dish, dynamic suspension culture in culture bag or agitation culture in culture tank.

[0033] This cell culture chamber fully considers the influence of cell-cell interaction on in vitro cultured cells in the process of large-scale cell culture, and uses membrane technology and co-cultivation methods to make co-cultured cells indirectly have a positive impact on the growth state of applied cells. Of course, the technique is also applicable to the study of various cell interactions (indirect contact).

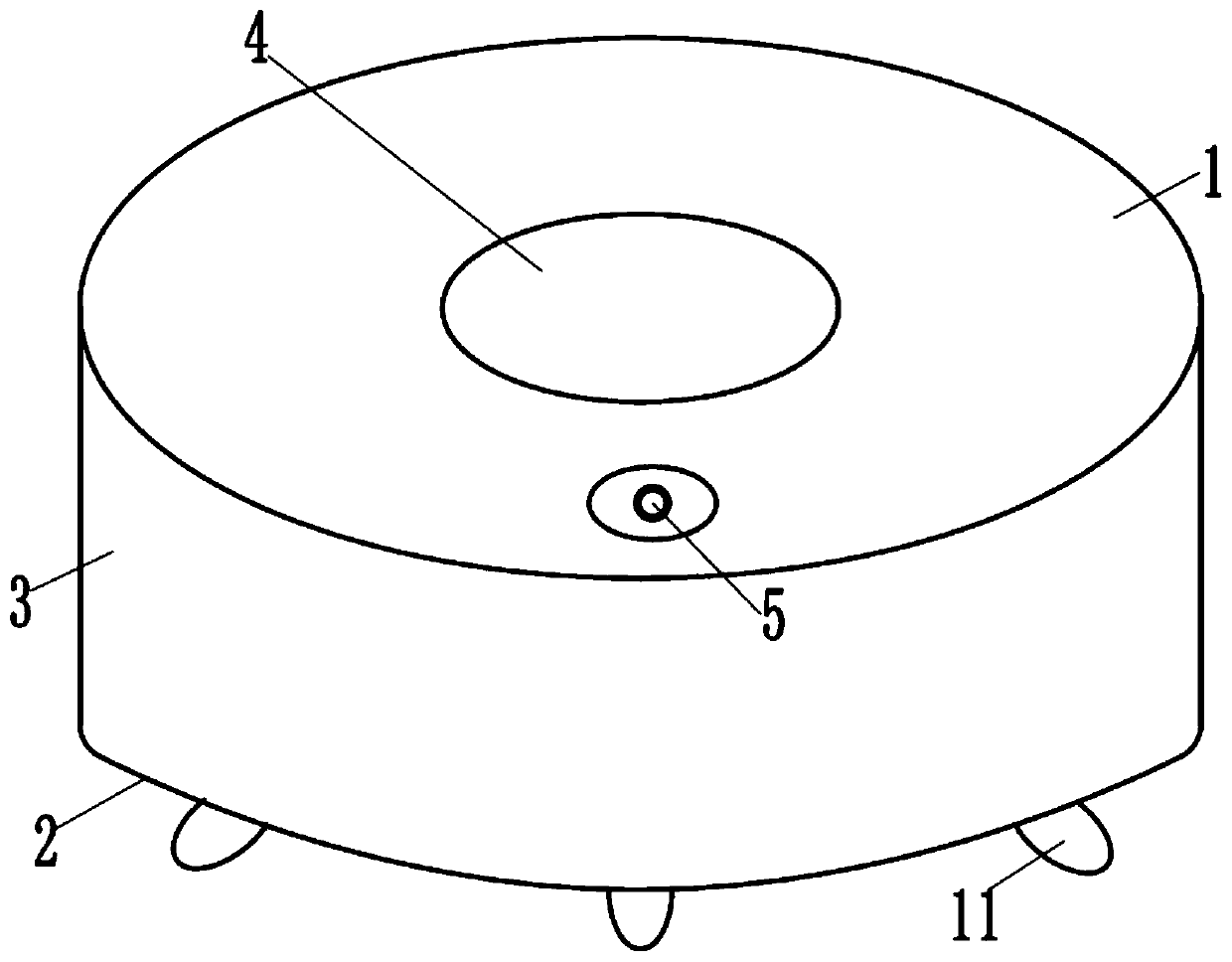

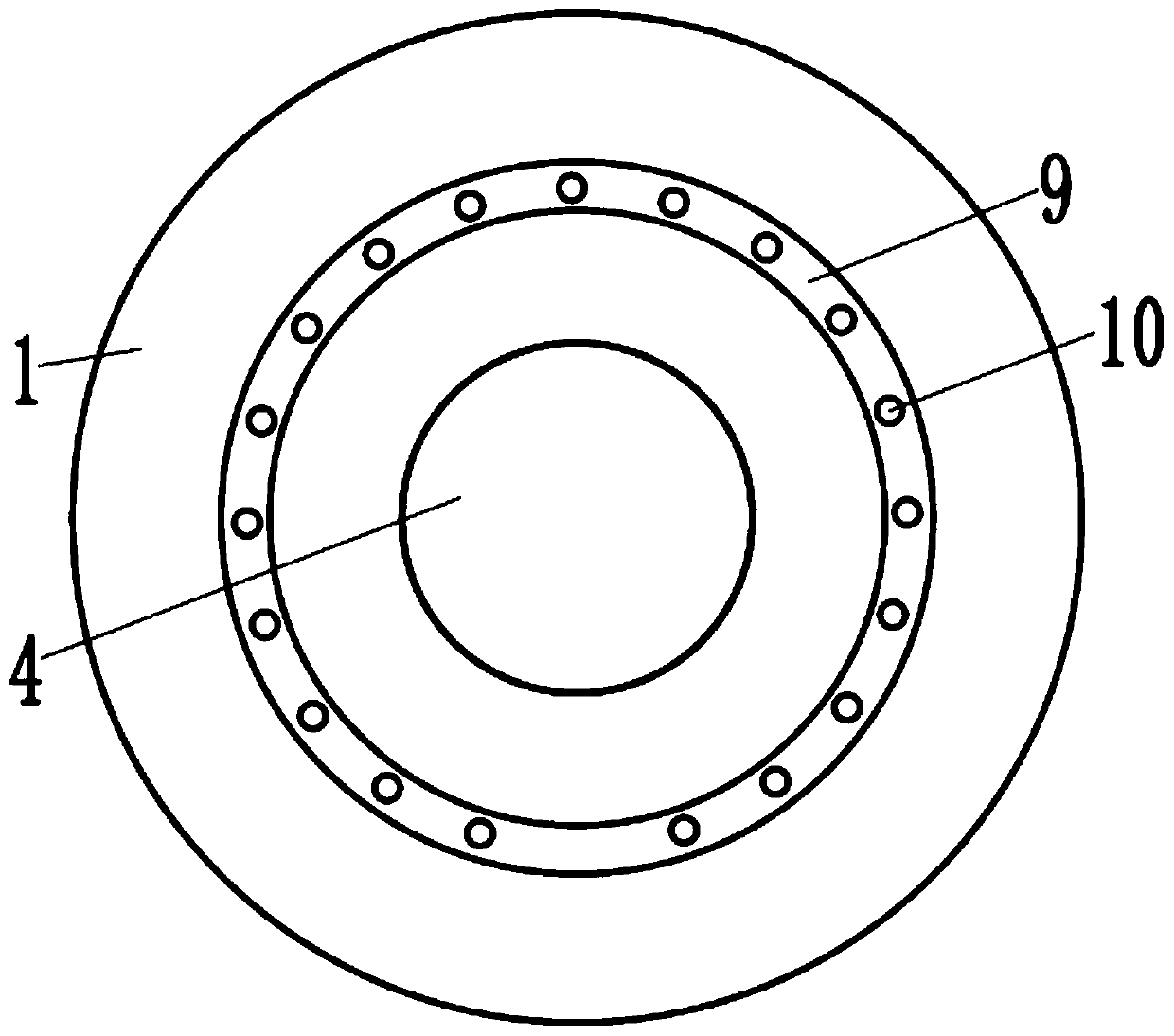

[0034] Such as figure 1 and figure 2 The cell culture chamber 16 shown includes a top plate 1, a bottom plate 2, a support member, a microporous membrane 3 and an airbag assembly, the top plate 1 and the bottom plate 2 are provided with through holes 4, and the top plate 1 and the bottom plate 2 are opposite to each other up ...

Embodiment 2

[0050] This embodiment is the same as embodiment 1 except the following technical features:

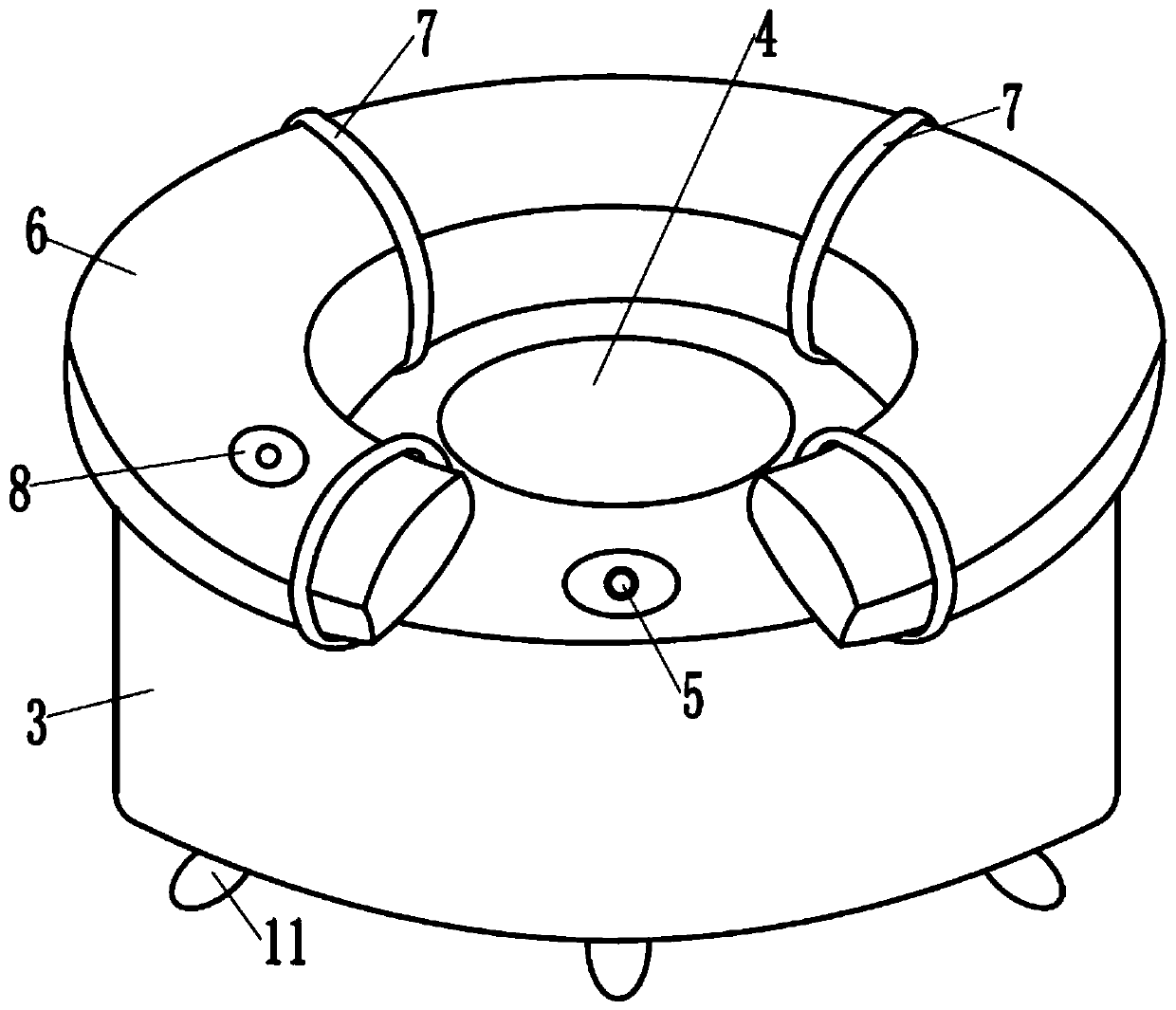

[0051] Such as Figure 4 As shown, the airbag 6 is cylindrical, the number of the airbag 6 is two, and the airbags 6 are arranged at intervals. The two airbags 6 are respectively located on both sides of the top plate 1, and the three sides of each airbag 6 are all convex. Out of the periphery of the microporous membrane located on the outside. This setting can increase the buoyancy of the chamber, making the chamber float above the culture system, which is beneficial to increase the gas exchange of the cells in the chamber, effectively prevent the violent collision between the chamber and the cell culture vessel, protect the structural stability of the chamber, and facilitate cell growth.

Embodiment 3

[0053] This embodiment is the same as embodiment 1 except the following technical features:

[0054] The airbags 6 are cylindrical, and the number of the airbags 6 is three. The airbags 6 are distributed in a ring shape and installed on the top plate 1. One side of each of the airbags 6 protrudes from the microporous membrane positioned on the outside. 3 perimeter. This setting can increase the buoyancy of the chamber, making the chamber float above the culture system, which is beneficial to increase the gas exchange of the cells in the chamber, effectively prevent the violent collision between the chamber and the cell culture vessel, protect the structural stability of the chamber, and facilitate cell growth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com