A glass with adjustable light intensity

A light intensity and adjustable technology, applied in parallel glass structures, shading screens, energy-saving measures, etc., can solve the problems of plant damage, manpower and material resources, etc., to achieve the effects of enhancing light, saving costs, and avoiding indoor overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

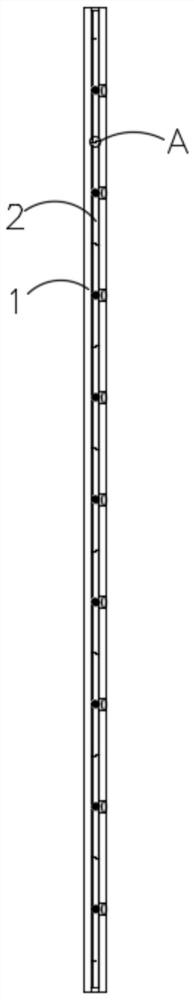

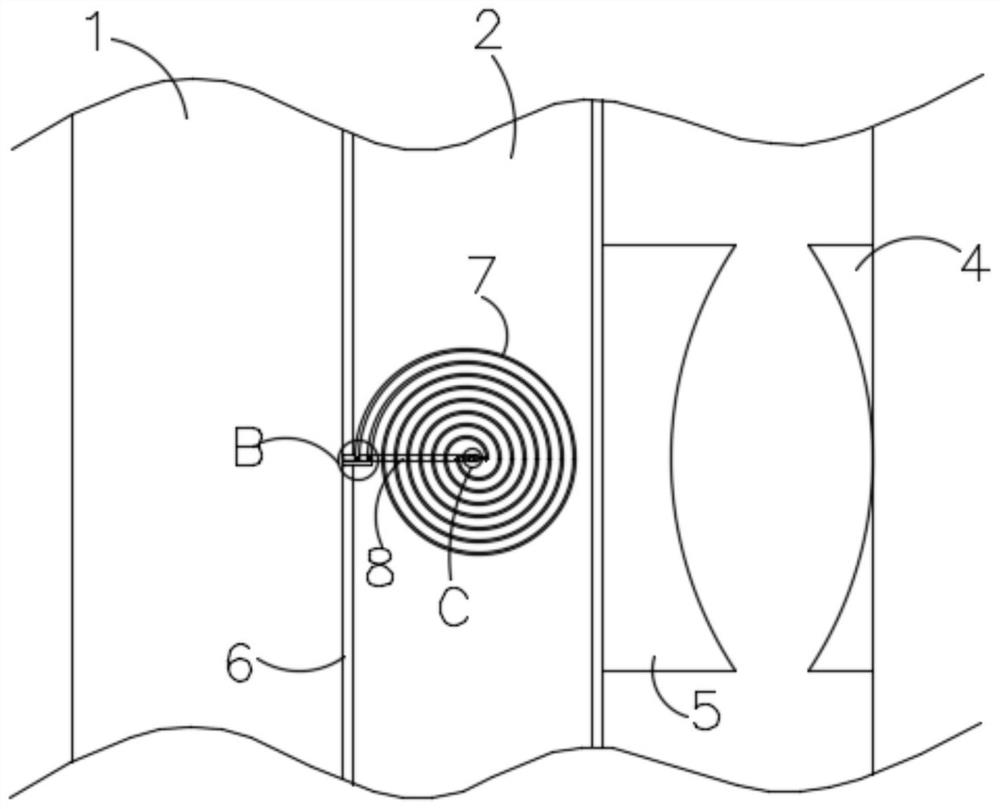

[0028] In the present invention, when the user uses the device, one side of the glass plate 1 with the outer arc-shaped concave surface 4 and the inner arc-shaped concave surface 5 faces the outdoor, and the side without the outer arc-shaped concave surface 4 and the inner arc-shaped concave surface 5 is opened. Facing the room, when sunlight irradiates on the surface of the glass plate 1 with high intensity, the outer curved concave surface 4 and the inner curved concave surface 5 cooperate with each other to form a convex lens structure, which can focus the light. The position of layer 7 is just at the focal point of the convex lens. The convex lens gathers the sun to heat up the mask layer 7. The convex lens is facing the memory metal strip. The memory metal is very sensitive to a specific temperature and will deform at a specific temperature. When the temperature of the memory metal strip rises, it will stretch out, and the whole mask layer 7 will be stretched out. When str...

Embodiment 2

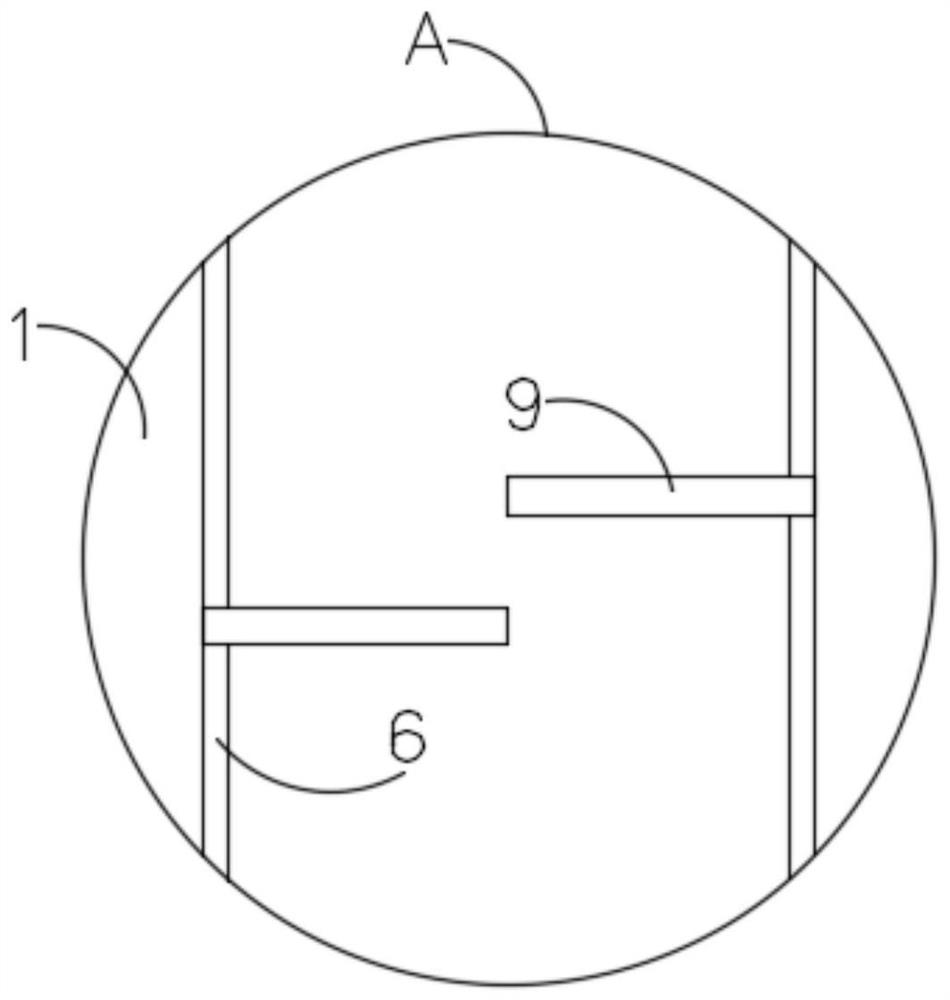

[0031] Wherein, the inner surfaces of the two glass plates 1 close to the chute 8 are provided with inner arc-shaped concave surfaces 5 , and the outer surfaces of the two glass plates 1 opposite to the inner arc-shaped concave surfaces 5 are provided with outer arc-shaped concave surfaces 4 .

[0032]Both glass plates 1 are provided with an inner arc-shaped concave surface 5 and an outer arc-shaped concave surface 4, and the inner arc-shaped concave surface 5 and the outer arc-shaped concave surface 4 are all set on both sides of the chute 8. At noon in the daytime, the glass The convex lens on the outside of the board 1 gathers the sunlight, so that each mask layer 7 is unfolded to refract the sunlight part. At this time, the outdoor sunlight is sufficient or even too high due to the sun, and the shading film has a blocking effect on the light. , only part of the light can be projected, and when the glass plate 1 is observed from the outside, the glass plate 1 will appear as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com