Indoor image type plumb aligner calibration device

A technology for calibration devices and image capture devices, which is applied in the direction of measuring devices, instruments, etc., can solve problems such as manual estimation and failure to meet the requirements of measurement standards, and achieve the effect of improving calibration efficiency and realizing automatic calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

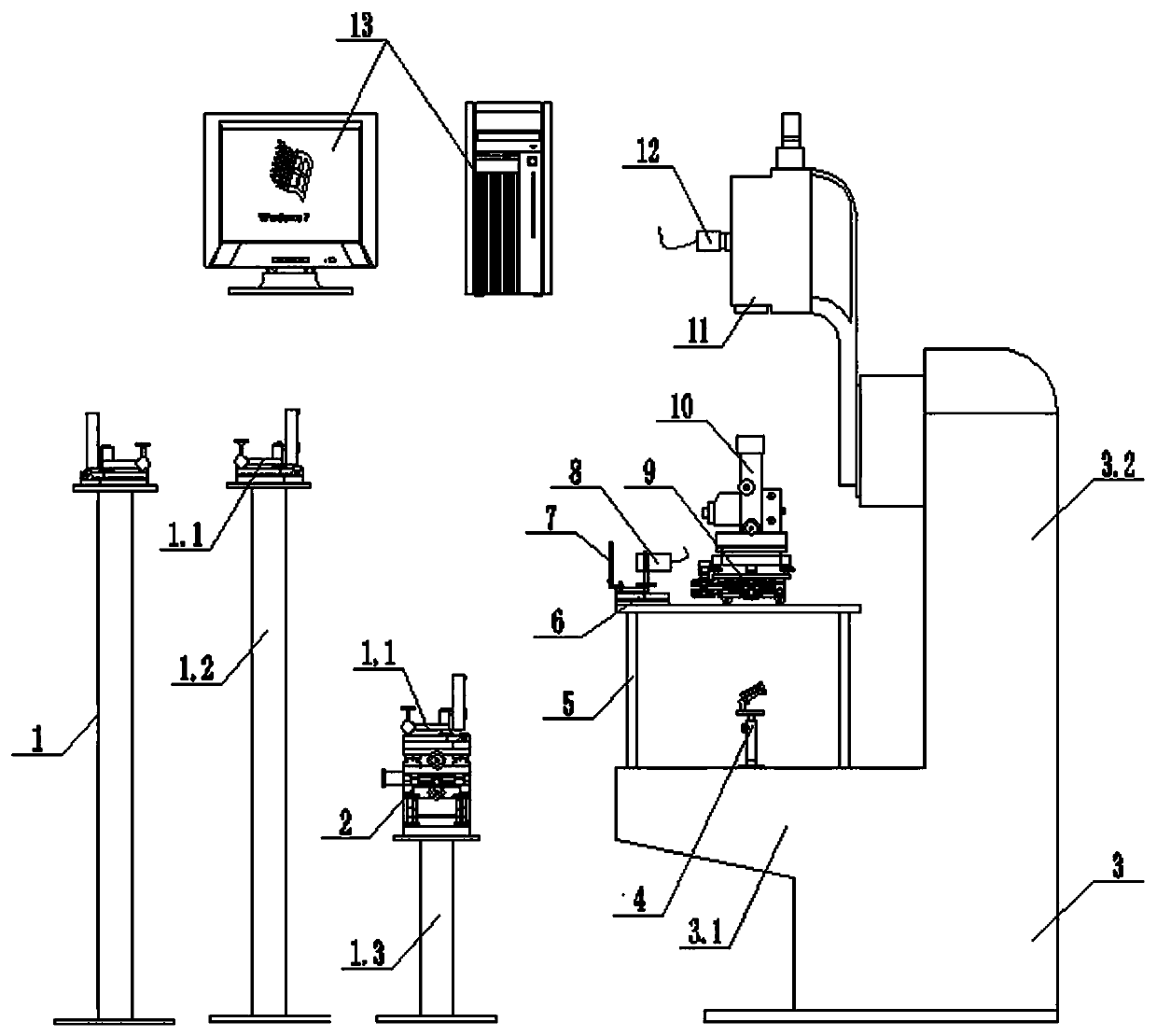

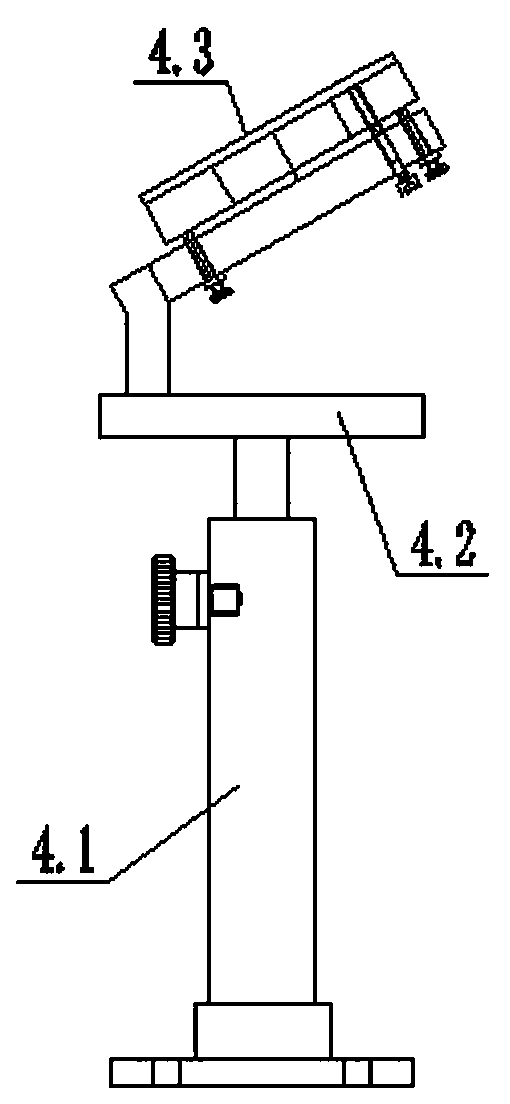

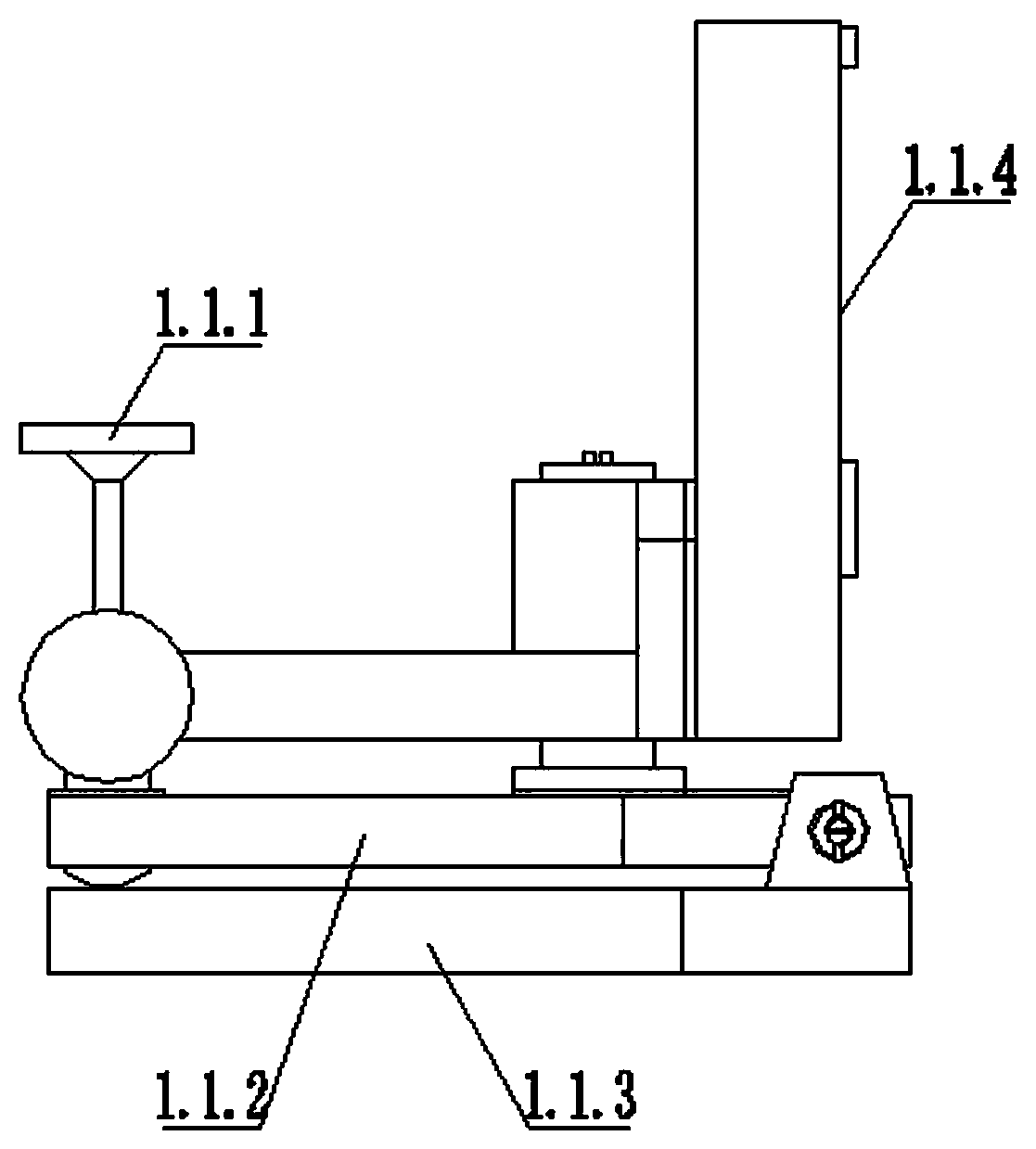

[0026] Such as figure 1 As shown, a kind of indoor image-type plummet calibration device includes an image processing system 13 and a work base 3, a work platform 3.1 is provided on the work base 3, a support frame 5 is provided on the work platform 3.1, and a support frame 5 is provided on the work platform 3.1. The frame 5 is fixed with a two-dimensional tilting platform 9 for carrying the plummet 10 to be calibrated, a support arm 3.2 integrally formed with the base 3 is provided beside the working platform 3.1, and a vertical support arm 3.2 is fixedly connected to the support arm 3.2. The collimator 11 arranged in the direction, the objective lens end of the collimator 11 is aligned downward to the upward vertical line position issued by the plummet 10 to be calibrated, and the first image capture device 12 is installed on the collimator 11, the first The image c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com