Cigarette

A cigarette and cigarette body technology, applied in the field of electronic cigarettes, can solve the problems of inconsistent smoking taste, sticky taste, and easy burning of tobacco, and achieve the effects of improving user experience, improving utilization rate, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

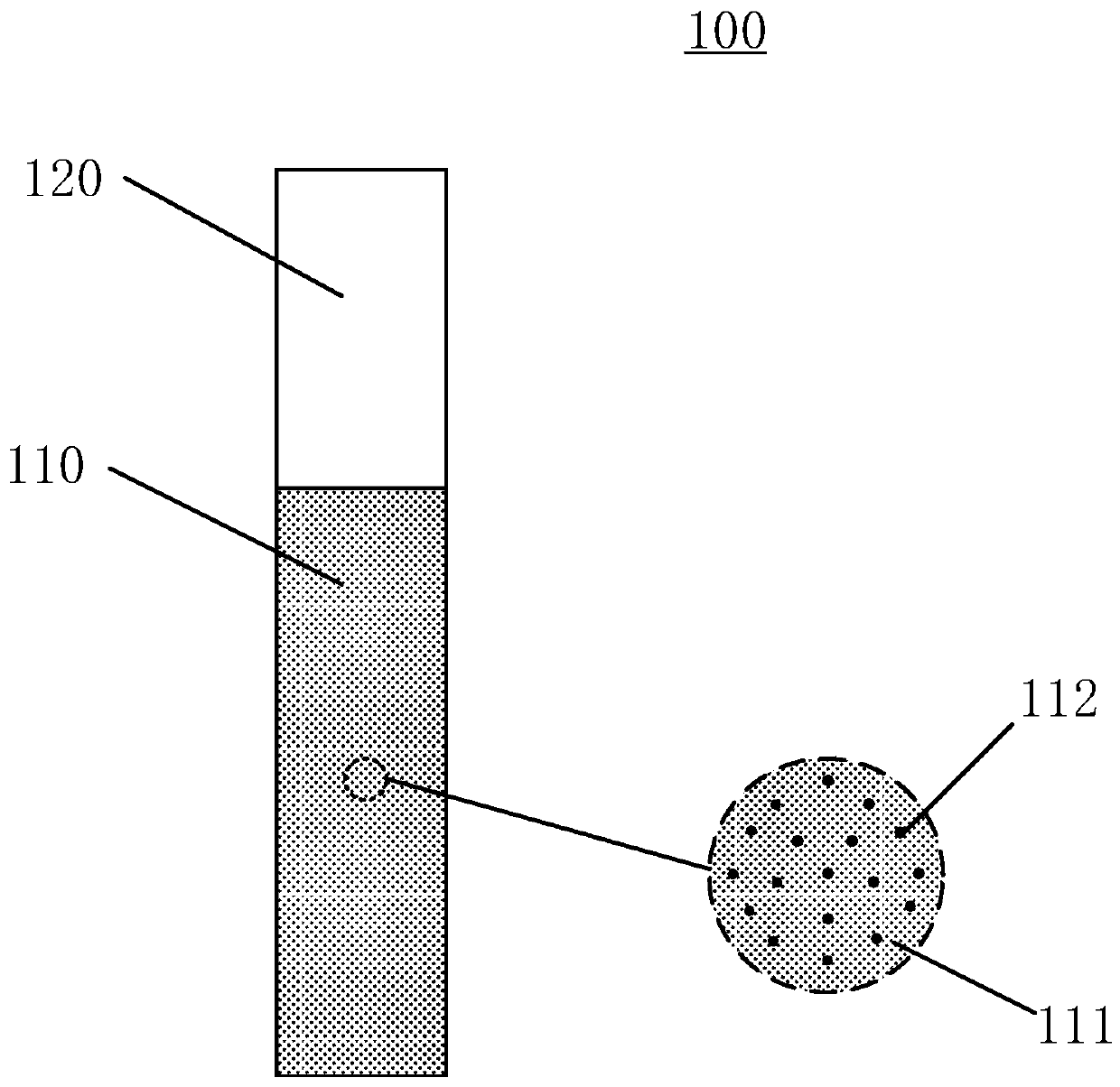

[0024] The magnetic substance 112 can be added to the tobacco 111 during the preparation of the cigarette 100 , so as to achieve uniform distribution in the tobacco 111 . For example, the tobacco 111 and the magnetic substance 112 can be uniformly mixed in advance, and then shaped into the tobacco body 110 by coating, die-casting or thermoplastic.

[0025] Adding magnetic substance 112 to tobacco 111 is beneficial to improve the thermal conductivity of smoke body 110. Specifically, the thermal conductivity of smoke body 110 can be no less than 0.15W / m·K, further 0.18W / m·K~2W / m·K is not only beneficial to promote the temperature uniformity when the smoke body 110 is heated up.

[0026] The above-mentioned cigarette 100 can be smoked by using a smoking appliance with an electromagnetic induction heating element. In one embodiment, the electromagnetic induction heating element can be an electromagnetic induction coil, which can be wound around the outside of the mechanism for lo...

Embodiment 1

[0030] This embodiment adopts zinc-manganese ferrite powder (the composition is 65% by weight of Fe 2 o 3 , 10 wt% ZnO, 24.87 wt% Mn 3 o 4 , 0.03 wt% CaO 2 , 0.05 wt% TiO 2 , 0.05 wt% ZrO 2 ) as a magnetic substance has a Curie temperature of 275°C, a particle size of 100μm, and a thermal conductivity of 5W / m·k.

[0031] Mix tobacco and zinc-manganese ferrite powder evenly, and shape it into a smoke body, wherein the zinc-manganese ferrite powder accounts for 10% of the total volume of the smoke body, and then connect the smoke body with the filter tip to obtain the following: figure 1 For the cigarette with the structure shown, the thermal conductivity of the test smoke body is 0.5W / m·K.

Embodiment 2

[0033] The preparation process of the cigarette of this embodiment is roughly the same as that of Example 1, the difference is that zinc-manganese ferrite powder (composition is 75% by weight of Fe 2 o 3 , 3 wt% ZnO, 21.87 wt% Mn 3 o 4 , 0.02 wt% CaO 2 , 0.03 wt% TiO 2 , 0.05 wt% ZrO 2 , 0.03 wt% TiO 2 ) as a magnetic substance has a Curie temperature of 325°C, a particle size of 150μm, and a thermal conductivity of 5.2W / m·k. The zinc-manganese alloy powder accounts for 1% by volume of the total volume of the smoke body, and the thermal conductivity of the smoke body is 0.15W / m·K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com