High-flux anti-pollution reverse osmosis membrane and preparation method thereof

A reverse osmosis membrane, anti-pollution technology, applied in the direction of reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of water flux decline, reduce adsorption, reduce flux decline, and increase service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A high-flux anti-fouling reverse osmosis membrane, which sequentially includes a polysulfone-based membrane layer, a polyamide desalination layer and a polyvinyl alcohol protective layer from bottom to top;

[0035] Described polyvinyl alcohol protective layer comprises the component of following mass parts: 1 part of polyvinyl alcohol, 0.5 part of nano-titanium dioxide modified clay mineral, 0.2 part of 3-aminopropyl silane triol and acid curing agent;

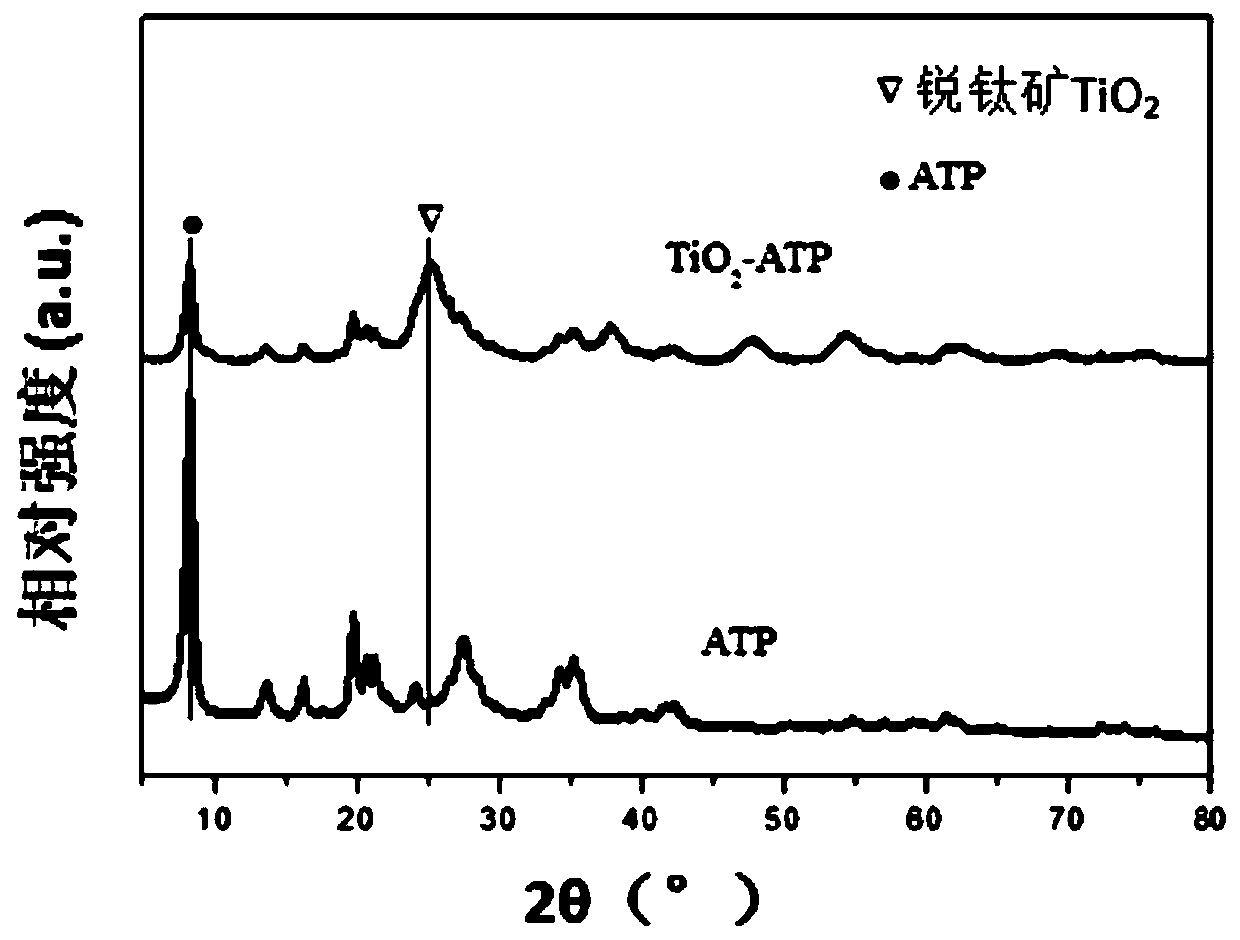

[0036] The nano-titanium dioxide modified clay mineral is nano-titanium dioxide modified attapulgite, and the acidic curing agent is citric acid, wherein the amount of citric acid is such that the pH of the modified polyvinyl alcohol protection solution is 5-6.

[0037] A method for preparing a high-throughput anti-fouling reverse osmosis membrane, comprising the steps of:

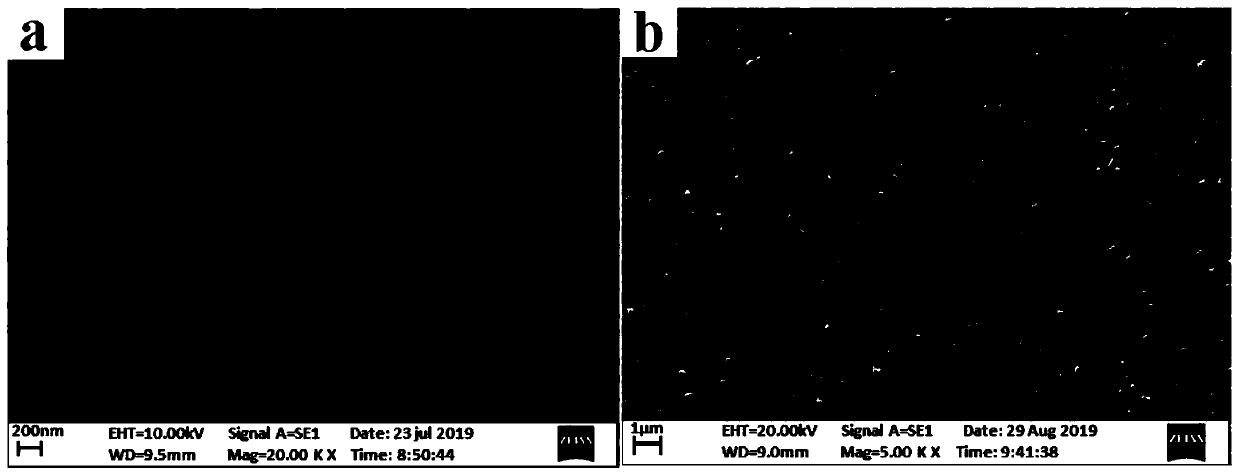

[0038] (1) First measure 10mL of 2.5mol / L TiCl 4The solution is in a three-necked flask, and the pH value of the solution is adjusted to neutrali...

Embodiment 2~5

[0047] A high-flux anti-fouling reverse osmosis membrane, which sequentially includes a polysulfone-based membrane layer, a polyamide desalination layer and a polyvinyl alcohol protective layer from bottom to top;

[0048] Described polyvinyl alcohol protective layer comprises the component of following mass parts: 1 part of polyvinyl alcohol, 0.5 part of nano-titanium dioxide modified clay mineral, 0.2 part of 3-aminopropyl silane triol and acid curing agent;

[0049] Described nano titanium dioxide modified clay mineral is nano titanium dioxide modified attapulgite, and described acid curing agent is citric acid, and wherein, the consumption of citric acid makes the pH of modified polyvinyl alcohol protection solution be 5-6 as the criterion;

[0050] Wherein, the nano-titanium dioxide in the nano-titanium dioxide modified attapulgite and the mass ratio of attapulgite in Examples 2-5 are different, as shown in Table 1.

[0051] The preparation method of high-throughput anti-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com