Ampoule bottle chain conveying device

A chain conveying device, chain conveyor technology, applied in the direction of conveyor, transportation, packaging, printing, etc., can solve the problems of inconvenient operation, ampoule bottle breaking, falling off, etc., and achieve the effect of convenient installation and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

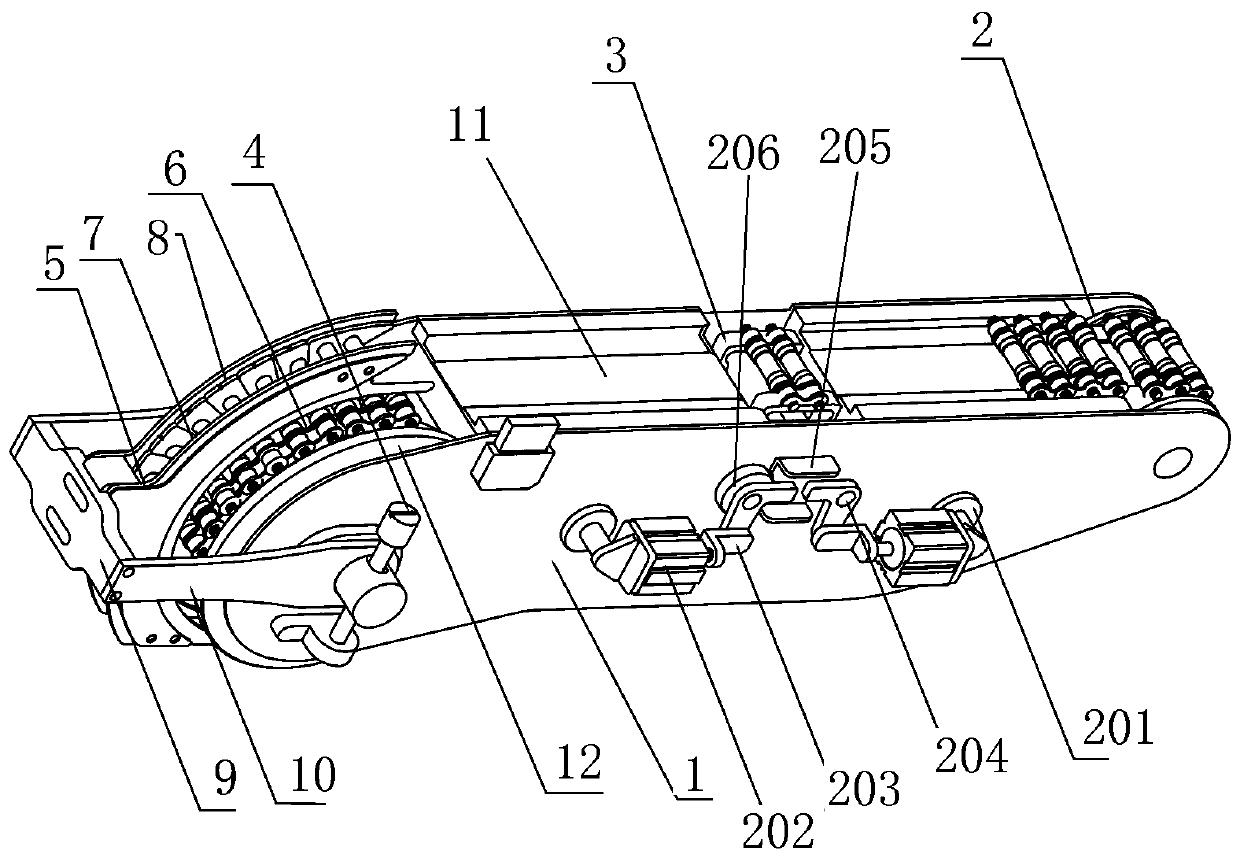

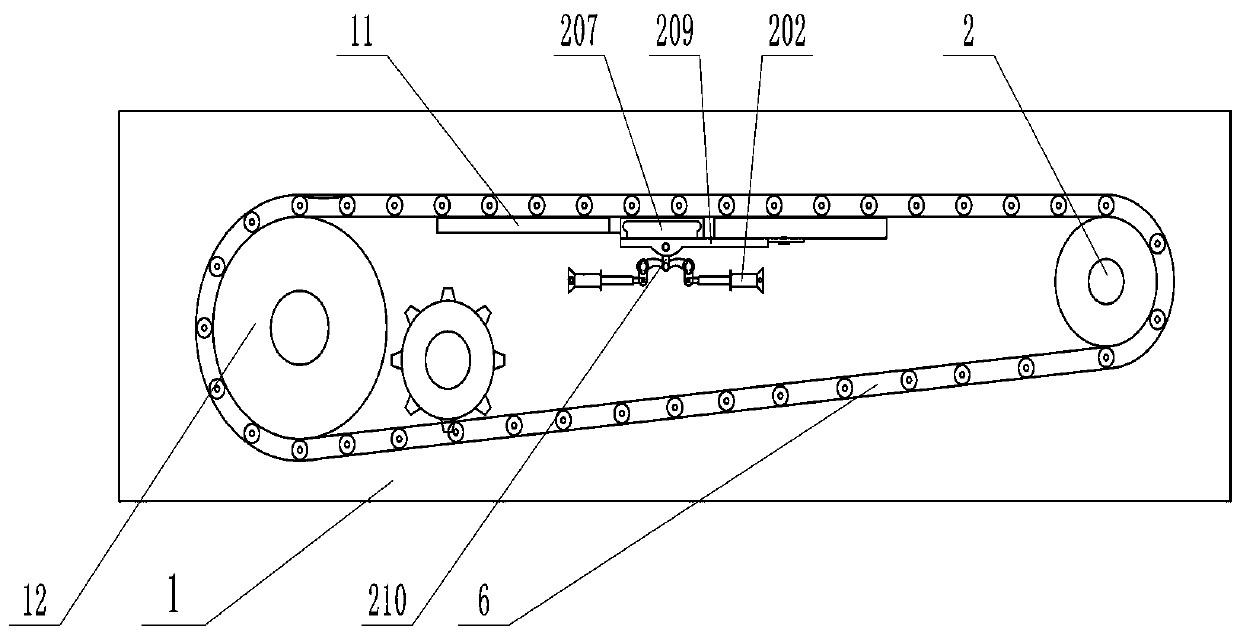

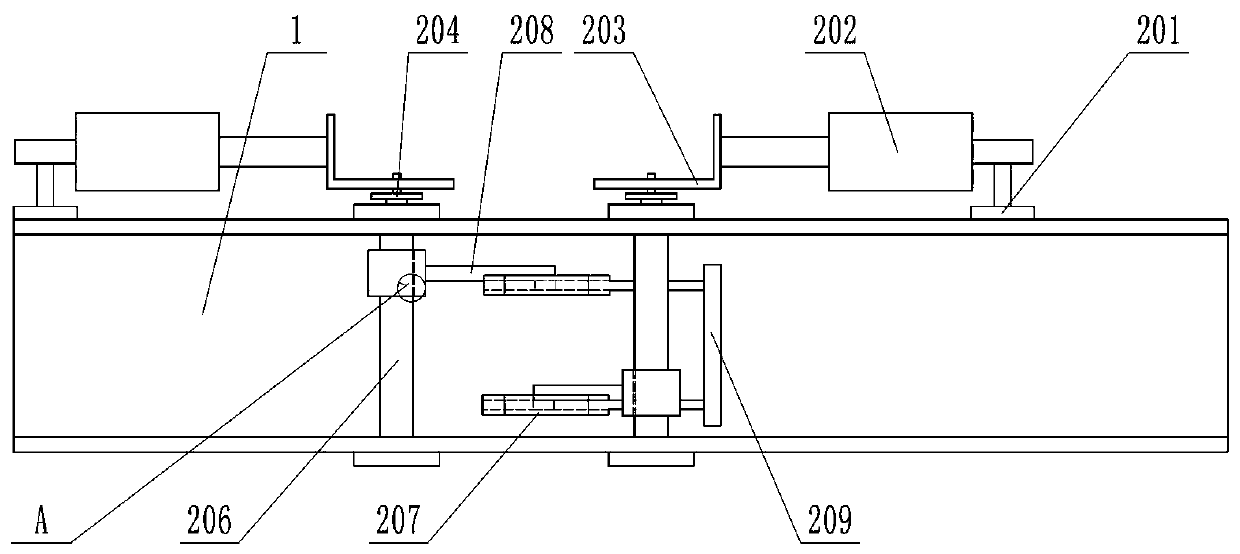

[0030] like Figure 1-8Shown, a kind of ampoule bottle chain conveying device comprises frame 1, and the chain conveyor for conveying ampoule bottle bottle is installed on frame 1, and chain conveyor comprises that is installed on the frame double-row endless chain 6, and frame Driven wheel one 2 and driven wheel two 12 are installed on the positions corresponding to the two ends of the endless chain, and a driven wheel adjusting lead screw 4 for adjusting the height of the driven wheel two is also installed on the frame corresponding to the position of driven wheel two 12, and the driven wheel adjusting screw 4 is installed on the frame. The adjustment principle of the bar 4 adopts a relatively mature structure in the prior art; a drive wheel is connected to the middle position of the corresponding double-row ring chain on the frame, and the drive wheel is connected to a drive motor, and the ring chain is equipped with a device that matches the ampoule bottle. Groove, by plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com