Low-power depolymerization emulsification viscosity reducer for heavy oil cold production and preparation method thereof

An emulsifying viscosity-reducing, low-power technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of not having a good emulsifying viscosity-reducing agent system, and achieve clean process, no pollution, easy product, and compounding. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1: Viscosity reducer D 1 and its preparation method

[0074] (1) Viscosity reducer D 1 The composition and its mass components are as follows:

[0075] Polyoxyethylene grafted polyacrylamide 0.1%;

[0076] Crown ether surfactant 40%;

[0077] Water 59.9%.

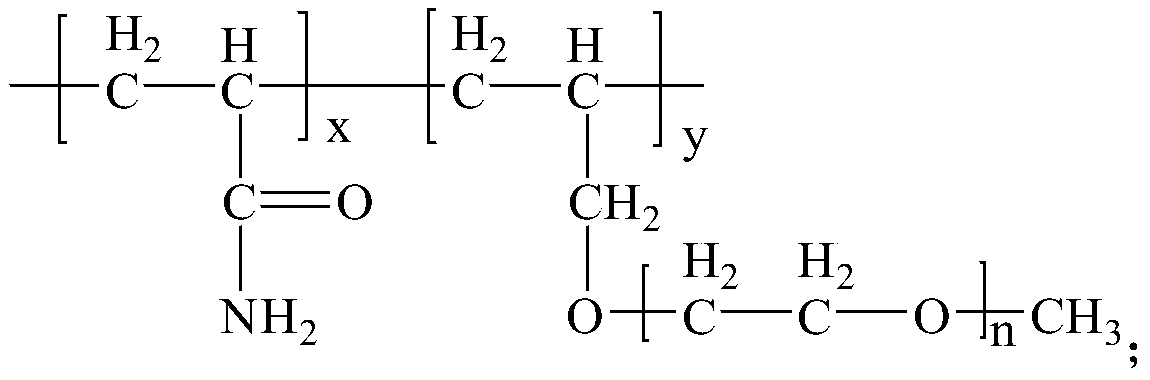

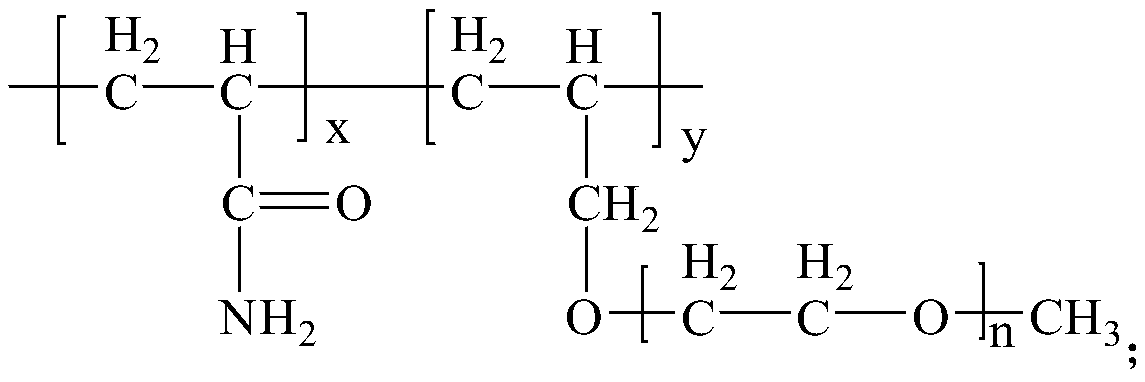

[0078] Described polyoxyethylene graft polyacrylamide, its molecular formula is as follows:

[0079]

[0080] Described crown ether surfactant, its general structural formula is as follows:

[0081]

[0082] where R is C 7 ~C 12 straight-chain alkyl groups.

[0083] (2) Viscosity reducer D 1 The preparation method is as follows:

[0084] ① First, weigh the crown ether surfactant and water, and stir for 10 minutes at a temperature of 30°C, a stirring rate of 100 rpm, and normal pressure to obtain a uniform and transparent aqueous solution;

[0085] ② Slowly add polyoxyethylene grafted polyacrylamide to the above aqueous solution, heat up to 60°C, stir at 300rpm for 1h, then cool to room tem...

Embodiment 2

[0086] Embodiment 2: Viscosity reducer D 2 and its preparation method

[0087] (1) Viscosity reducer D 2 The composition and its mass components are as follows:

[0088] Polyoxyethylene grafted polyacrylamide 1.0%;

[0089] Crown ether surfactant 45%;

[0090] Water 54%.

[0091] Described polyoxyethylene graft polyacrylamide, its molecular formula is as follows:

[0092]

[0093] Described crown ether surfactant, its general structural formula is as follows:

[0094]

[0095] (2) Viscosity reducer D 2 The preparation method is as follows:

[0096] ① First, weigh the crown ether surfactant and water, and stir for 12 minutes at a temperature of 32°C, a stirring rate of 120 rpm, and normal pressure to obtain a uniform and transparent aqueous solution;

[0097] ② Slowly add polyoxyethylene grafted polyacrylamide to the above aqueous solution, raise the temperature to 65°C, stir at a rate of 350rpm, and stir for 1.2h, then cool to room temperature to obtain the visco...

Embodiment 3

[0098] Embodiment 3: Viscosity reducer D 3 and its preparation method

[0099] (1) Viscosity reducer D 3 The composition and its mass components are as follows:

[0100] Polyoxyethylene grafted polyacrylamide 2.5%;

[0101] Crown ether surfactant 52%;

[0102] Water 45.5%.

[0103] Described polyoxyethylene graft polyacrylamide, its molecular formula is as follows:

[0104]

[0105] Described crown ether surfactant, its general structural formula is as follows:

[0106]

[0107] where R is C 7 ~C 12 of alkylamides.

[0108] (2) Viscosity reducer D 3 The preparation method is as follows:

[0109] ① First, weigh the crown ether surfactant and water, and stir for 13 minutes at a temperature of 35°C, a stirring rate of 200 rpm, and normal pressure to obtain a uniform and transparent aqueous solution;

[0110] ② Slowly add polyoxyethylene grafted polyacrylamide to the above aqueous solution, heat up to 62°C, stir at 320rpm, stir for 1.5h, and then cool to room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com