Device and method for calcining oxidized pellets aerobically

A technology of oxidizing pellets and roasting, which is applied in the field of iron and steel metallurgy, can solve the problems of high FeO content and insufficient oxygen supply of pellets, and achieve the effect of reducing the content of FeO

Active Publication Date: 2020-01-10

PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to overcome the problems of insufficient oxygen supply and high content of FeO in the pellets during the roasting process due to the closed heating method existing in the prior art, and to provide a method for aerobic roasting and oxidation of pellets. Device and method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-3

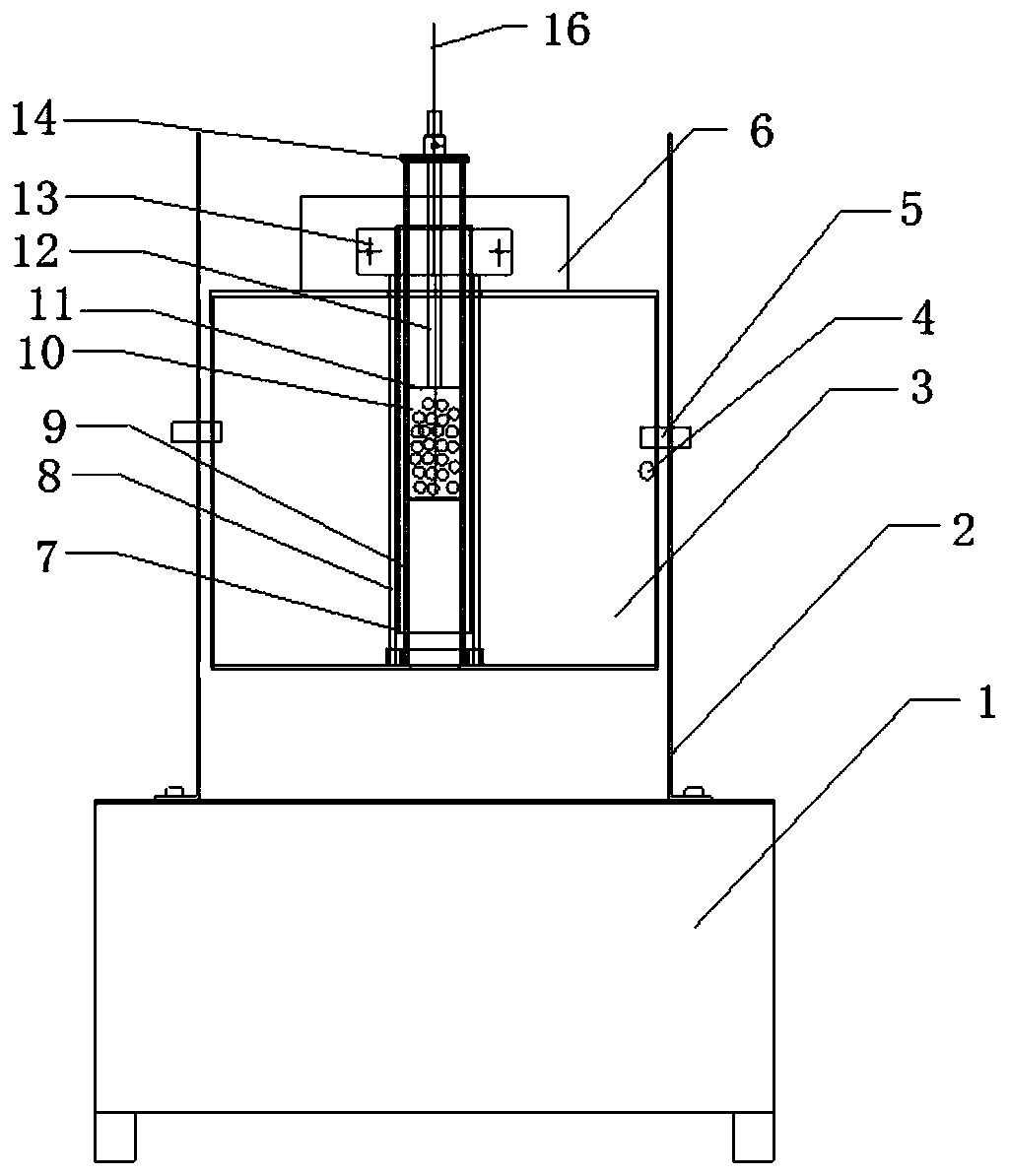

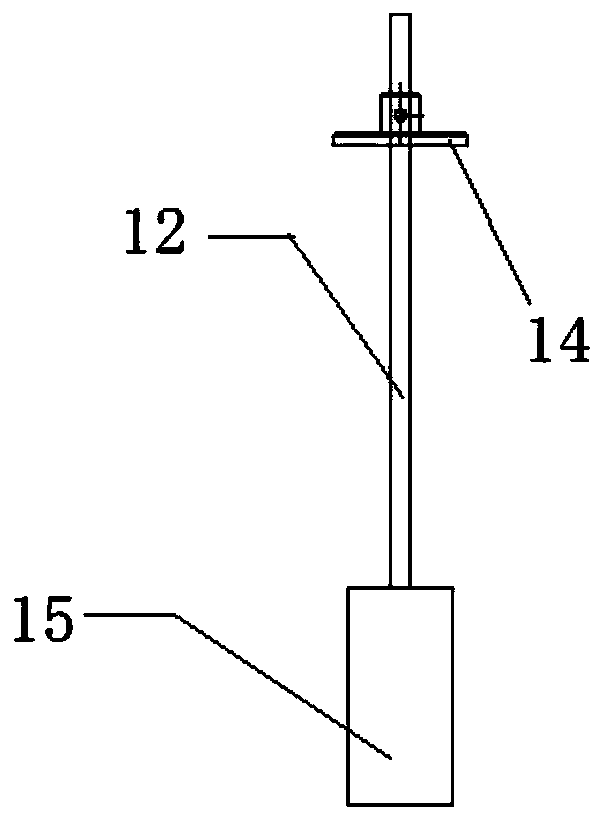

[0071] Weigh 500g of the sample 10, put it into the high temperature container 15 of the high temperature sample container 11, and carry out the roasting reaction in the constant temperature area inside the corundum protection tube 9 inside the high temperature sample container 11 containing the sample 10.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to the field of ferrous metallurgy and discloses a device and a method for calcining oxidized pellets aerobically. The device comprises a base, at least one furnace body supporting plate, a furnace body, a silicon carbide tube heater, an outer corundum protecting tube, an inner corundum protecting tube and a high-temperature specimen container. The furnace body supporting plates are vertically arranged on the base, the furnace body is mounted on the furnace body supporting plates, the outer corundum protecting tube is vertically arranged at the bottom of the furnace body,the silicon carbide tube heater is vertically arranged on the inner side of the outer corundum protecting tube, and the high-temperature specimen container is detachably mounted on the inner side ofthe inner corundum protecting tube and comprises a specimen container supporting plate, a specimen thermocouple tube and a high-temperature container. The device can guarantee that a specimen is heated in a ventilating state, so that the specimen is in air all the way, and therefore, an oxidative atmosphere is supplied sufficiently; therefore, the content of FeO in prepared pellets is reduced, anda reliable ground and guidance can be provided for industrial production.

Description

technical field [0001] The invention relates to the field of iron and steel metallurgy, in particular to a device and method for aerobically roasting and oxidizing pellets. Background technique [0002] Pellets are mixed with iron-containing concentrate powder and binder in a certain proportion, and then made into green balls with a diameter of 8-15mm in a pelletizer, and then dried, roasted and consolidated to form a pellet with good Iron-containing raw material with excellent metallurgical properties, used for blast furnace smelting. The main process of pellet production includes raw material preparation, batching, mixing, pelletizing, drying, preheating, roasting and cooling. Pellet products have been used in steelmaking and direct reduction ironmaking. Compared with sinter, pellets have better metallurgical properties, uniform particle size, more micropores and good reducibility, and a large number of popularization and use are conducive to strengthening blast furnace ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22B1/02

CPCC22B1/02

Inventor 朱凤湘胡鹏

Owner PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com