Hydrogen-mixed natural gas pipeline valve chamber safe emptying system and method

A technology for a hydrogen-mixed natural gas and venting system is applied in the field of safe venting system of a valve chamber of a hydrogen-mixed natural gas pipeline, which can solve the problem of frictional spontaneous combustion, and it is also possible that the medium may be ignited by the outside near the nozzle when the medium leaves the venting riser, which is easy to induce deflagration or explosion. and other problems, to achieve the effect of ensuring the release rate, preventing the release and spreading, and avoiding safety problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

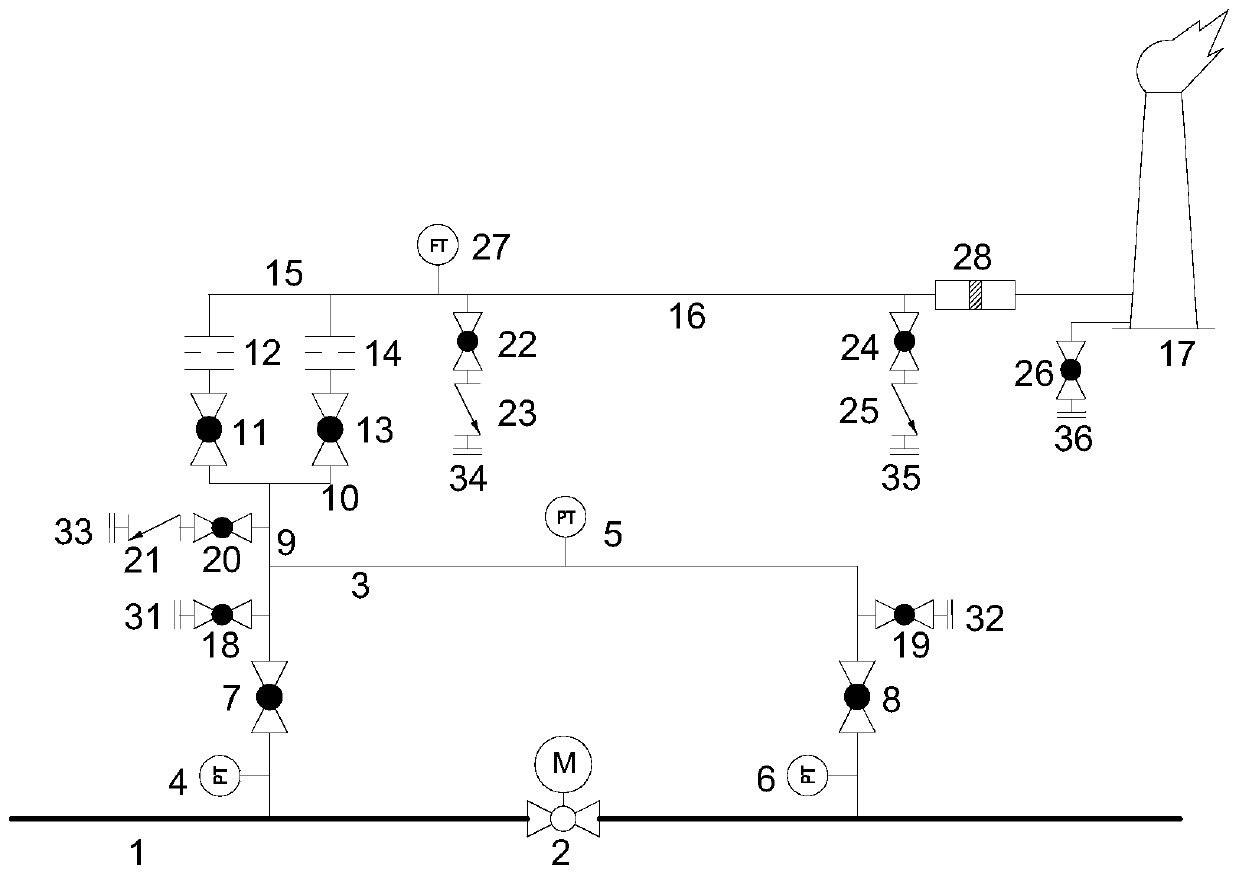

[0024] A safety venting system for a hydrogen-mixed natural gas pipeline valve room, mainly including: main line pipeline 1, cut-off ball valve 2, main line bypass 3, pressure transmitter 4 / 5 / 6, bypass cut-off valve 7 / 8, bypass external pipeline 9. High-pressure branch pipe 10, vent shut-off valve 11 / 13, flow-limiting orifice plate 12 / 14, vent manifold 15, vent main pipe 16, vent torch 17, replacement gas injection branch pipe 31 / 32, replacement exhaust branch pipe 33 / 34 / 35, torch cushion gas injection branch pipe 36, shut-off valve 18 / 19 / 20 / 22 / 24 / 26, check valve 21 / 23 / 25, flow transmitter 27, flame arrester 28.

[0025] Among them, the main line cut-off system such as main line pipeline 1, cut-off ball valve 2, main line bypass 3, bypass cut-off valve 7 / 8, pressure transmitter 4 / 5 / 6, etc., is responsible for instructing when the upstream or downstream of the pipeline fails or needs maintenance. The cut-off ball valve is closed to isolate the upstream and downstream for parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com