Composite proton exchange membrane and preparation method thereof

A technology of proton exchange membrane and mesoporous silica, which is applied in the field of proton exchange membrane, can solve the problems of poor conductivity stability and reduced conductivity, and achieve the effect of improving conductivity, long pore depth and good water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] Preparation of Sulfonated Polyetheretherketone (SPEEK)

[0077] Sulfonated polyetheretherketone (SPEEK) was prepared by direct sulfonation method using the above commercially available polyetheretherketone (PEEK). The specific steps are as follows: the polyether ether ketone (PEEK) powder is placed in a drying oven and dried at 80° C. for 12 hours. Put 20 g of dry PEEK powder and 250 mL of concentrated sulfuric acid into a 500 mL three-neck flask, and stir at room temperature for 15 min until PEEK dissolves in concentrated sulfuric acid. Then the three-neck flask was transferred to a magnetically stirred water bath at 50° C., and stirred at a speed of 200-400 r / min for 4 h. After the reaction, the reaction liquid was dropped into the ice-water mixture to terminate the sulfonation reaction, and the stirring was continued at room temperature for 12 h. The reaction product SPEEK was washed with a large amount of deionized water until the filtrate was neutral, then dried ...

Embodiment 1

[0094] Sulfonated polyether ether ketone with 47% degree of sulfonation 0.7500g

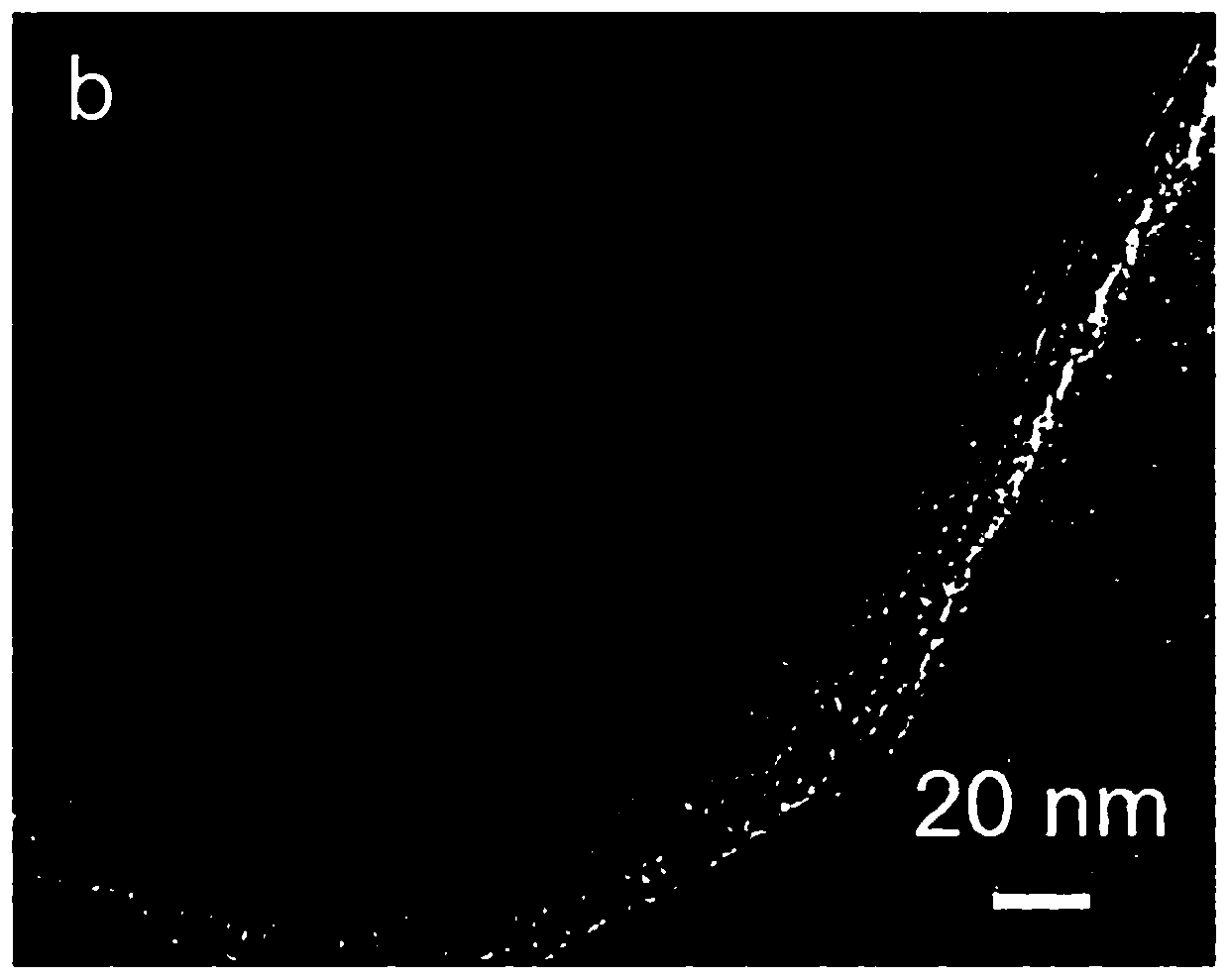

[0095] Rod-shaped modified mesoporous silica particles 0.0040g

[0096] Phosphotungstic acid 0.0397g

[0097] Add 5 g of dimethyl sulfoxide solvent into a 20 ml sample bottle, and then add 0.75 g of sulfonated polyether ether ketone with a sulfonation degree of 47%. Transfer the sample vial to a magnetic stirring water bath, heat to 60°C, and maintain stirring to completely dissolve the sulfonated polyetheretherketone to obtain a sulfonated polyetheretherketone dimethyl sulfoxide solution with a concentration of 13 wt%.

[0098] Then, in another 20ml beaker, first add 2g of dimethyl sulfoxide, and then add 0.0040g of rod-shaped modified mesoporous silica particles modified by KH-550 amino group, ultrasonic treatment for 10min, the ultrasonic frequency is 40KHz , so that silicon dioxide is uniformly dispersed in dimethyl sulfoxide solvent to obtain a suspension. Then add 0.0397g of phosphotungs...

Embodiment 2

[0101] Sulfonated polyether ether ketone with 55% sulfonation degree 0.75g

[0102] Spherical modified mesoporous silica particles 0.0040g

[0103] Phosphotungstic acid 0.0397g

[0104] Add 5 g of dimethyl sulfoxide solvent into a 20 ml sample bottle, and then add 0.75 g of sulfonated polyether ether ketone with a sulfonation degree of 55%. Transfer the sample vial to a magnetic stirring water bath, heat to 60°C, and maintain stirring to completely dissolve the sulfonated polyetheretherketone to obtain a sulfonated polyetheretherketone dimethyl sulfoxide solution with a concentration of 13 wt%.

[0105] Then, in another 20ml sample bottle, first add 2g of dimethyl sulfoxide, then add 0.0040g of spherical modified mesoporous silica particles modified by KH-550 amino groups, and perform ultrasonic treatment for 10min at a frequency of 40KHz, the silicon dioxide is uniformly dispersed in the dimethyl sulfoxide solvent to obtain a suspension. Then add 0.0397g of phosphotungstic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com