Method for preparing polyethylene glycol 4000 powder

A polyethylene glycol and solvent technology, which is applied in pharmaceutical formulations, medical preparations with non-active ingredients, and active ingredients of artificially synthesized polymeric materials, etc. It can improve the compliance of clinical use and improve the efficiency of mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

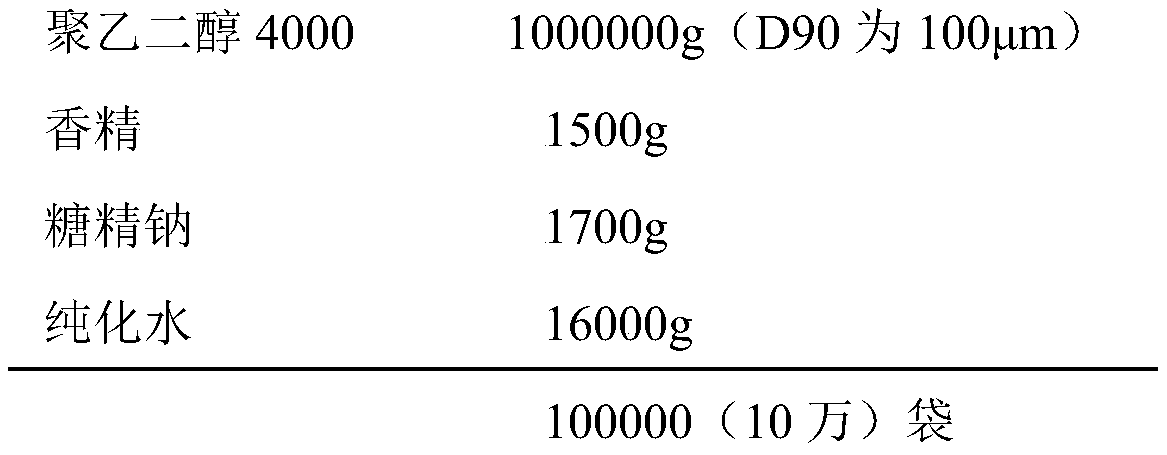

[0022] prescription:

[0023]

[0024] Preparation Process:

[0025] Weigh the prescription amount of essence and sodium saccharin into the batching tank, add 16000g of purified water, stir to fully dissolve the auxiliary materials, and transfer them into the material chamber of the spray gun. Weigh 1,000,000 g of polyethylene glycol 4,000 into a double-cone mixer, and start stirring. Open the valve of the spray gun and spray 10% of the total volume of the auxiliary material solution per minute. After spraying, continue to stir for about 10 minutes, and then transfer the material to the packaging machine to complete packaging of 100,000 (100,000) bags.

[0026] The test results of uniformity of excipients: Since the essence and sodium saccharin are sprayed into polyethylene glycol 4000 in the form of a solution, the content uniformity index of sodium saccharin is used to characterize the uniformity of the mixture. Respectively randomly take 5 bags of each of the initial,...

Embodiment 2

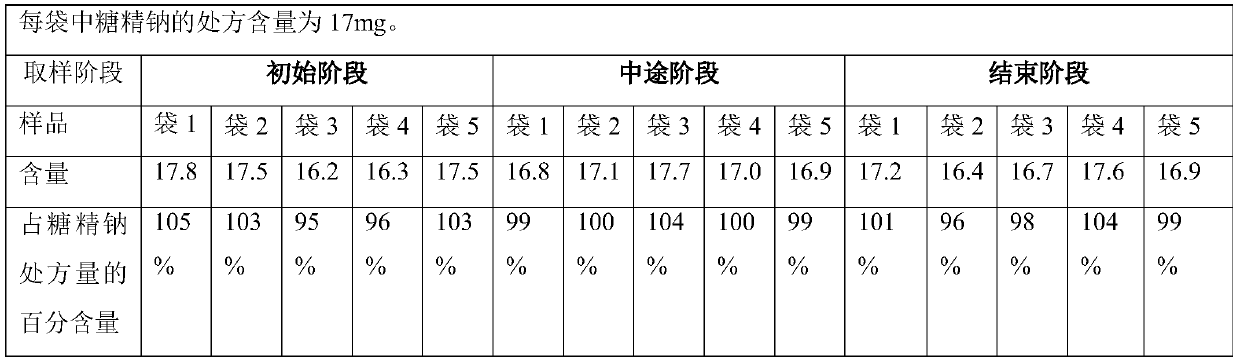

[0029] prescription:

[0030]

[0031]

[0032] Preparation Process:

[0033] Weigh the prescription amount of essence and sodium saccharin into a 500ml beaker, add 256g of purified water, stir to fully dissolve the auxiliary materials, and transfer them into the material cavity of the spray gun. Weigh 10000g polyethylene glycol 4000 into the three-dimensional cone mixer, and start stirring. Open the spray gun valve and spray 20% of the total volume of the auxiliary material solution per minute. After spraying, continue to stir for about 10 minutes, and then transfer the material to the packaging machine to complete packaging of 1000 bags.

[0034] Excipient material homogeneity measurement result: detection method is with embodiment 1, and result is as follows:

[0035]

Embodiment 3

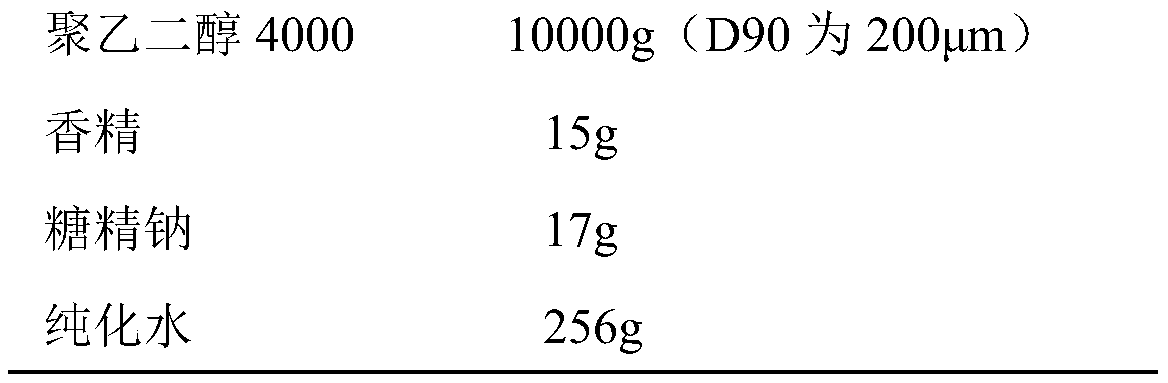

[0037] prescription:

[0038]

[0039] Preparation Process:

[0040] Weigh the prescription amount of essence and sodium saccharin into a 500ml beaker, add 192g of purified water, stir to fully dissolve the auxiliary materials, and transfer them into the material chamber of the spray gun. Weigh 10000g polyethylene glycol 4000 into the swing cone mixer and start stirring. Open the spray gun valve and spray 15% of the total volume of the auxiliary material solution per minute. After spraying, continue to stir for about 10 minutes, and then transfer the material to the packaging machine to complete packaging of 1000 bags.

[0041] Excipient material homogeneity measurement result: detection method is with embodiment 1, and result is as follows:

[0042]

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com