Method and system for modifying treatment of high-viscosity sea mud

A treatment method and high-viscosity technology, which is applied in sludge treatment, water/sludge/sewage treatment, fixed/solidified sludge treatment, etc. Large-scale resource processing and other issues to achieve high efficiency and avoid harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

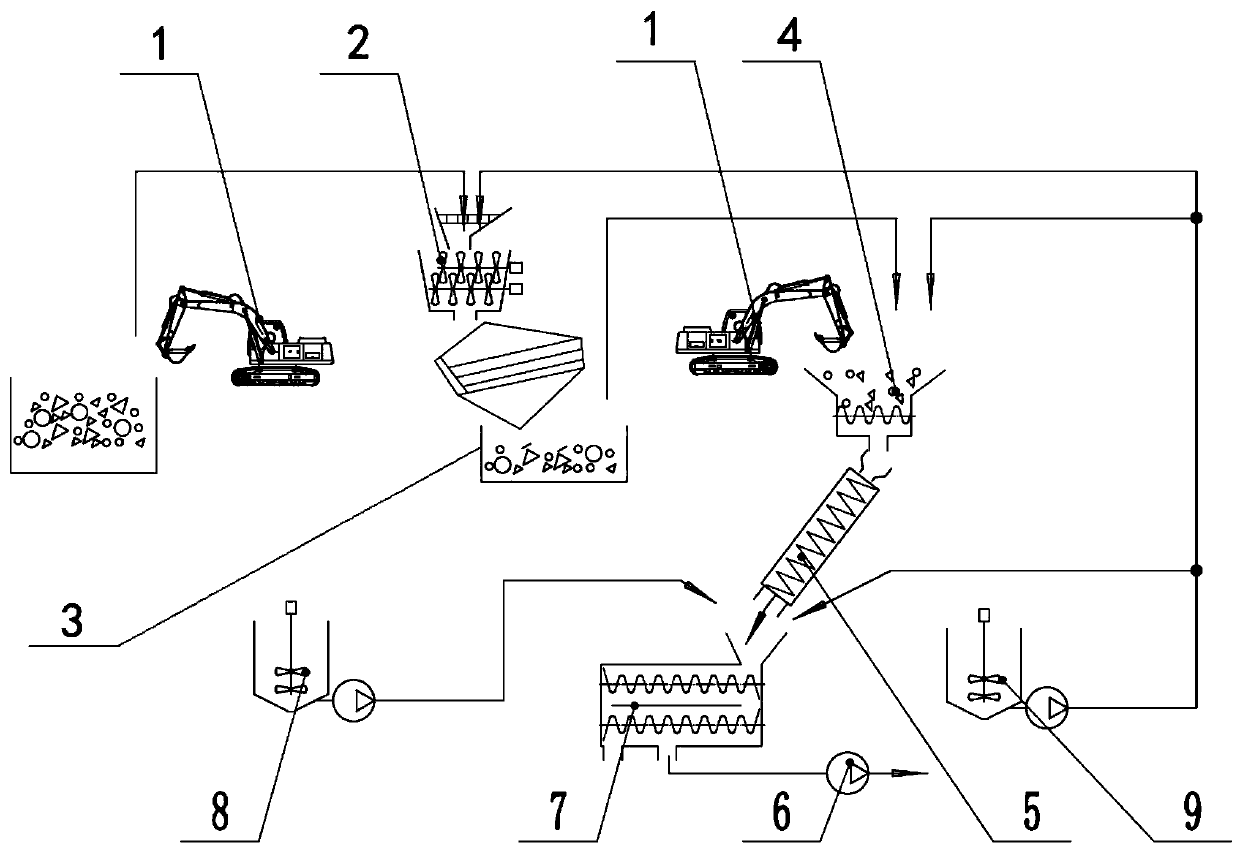

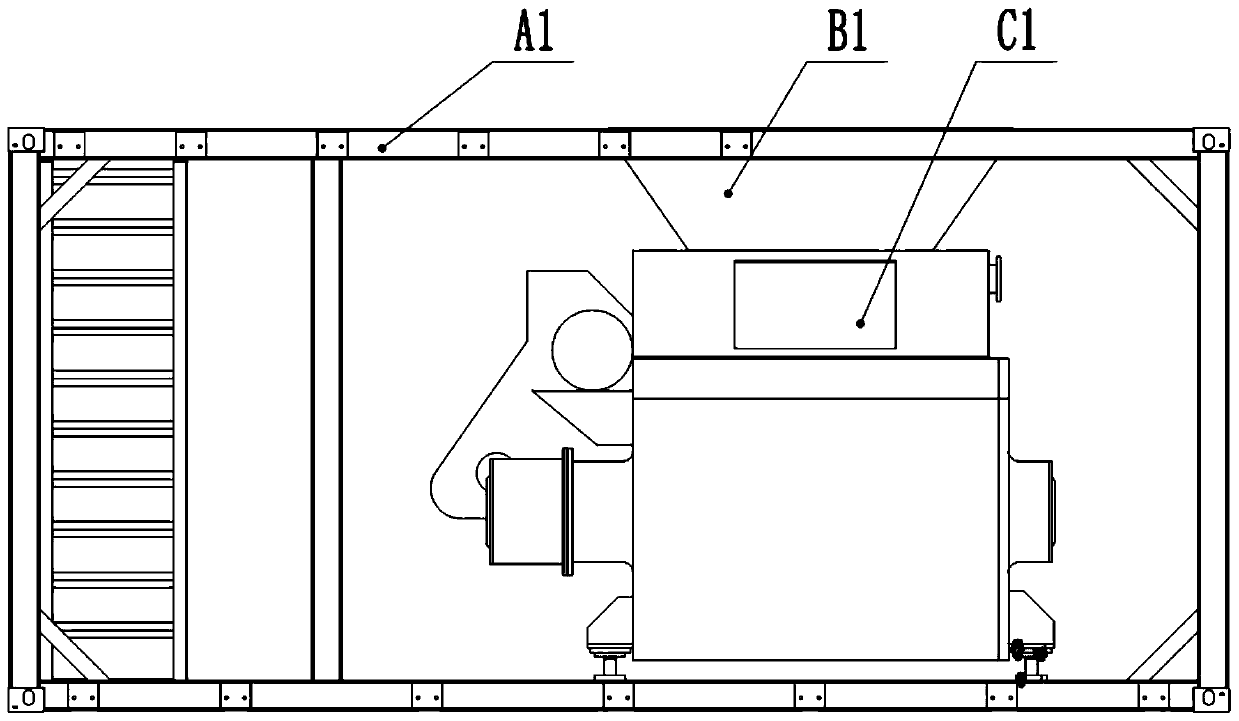

[0056] The high-viscosity sea mud modification treatment method of the present invention comprises the following steps,

[0057] S1, add polyacrylamide with a volume of 0.2‰ of sea mud to the sea mud and disperse until the sea mud clumps with a diameter of less than 30 mm account for ≥90%. The function of the initial dispersion is to disperse the agglomerated sea mud mass and increase its fluidity.

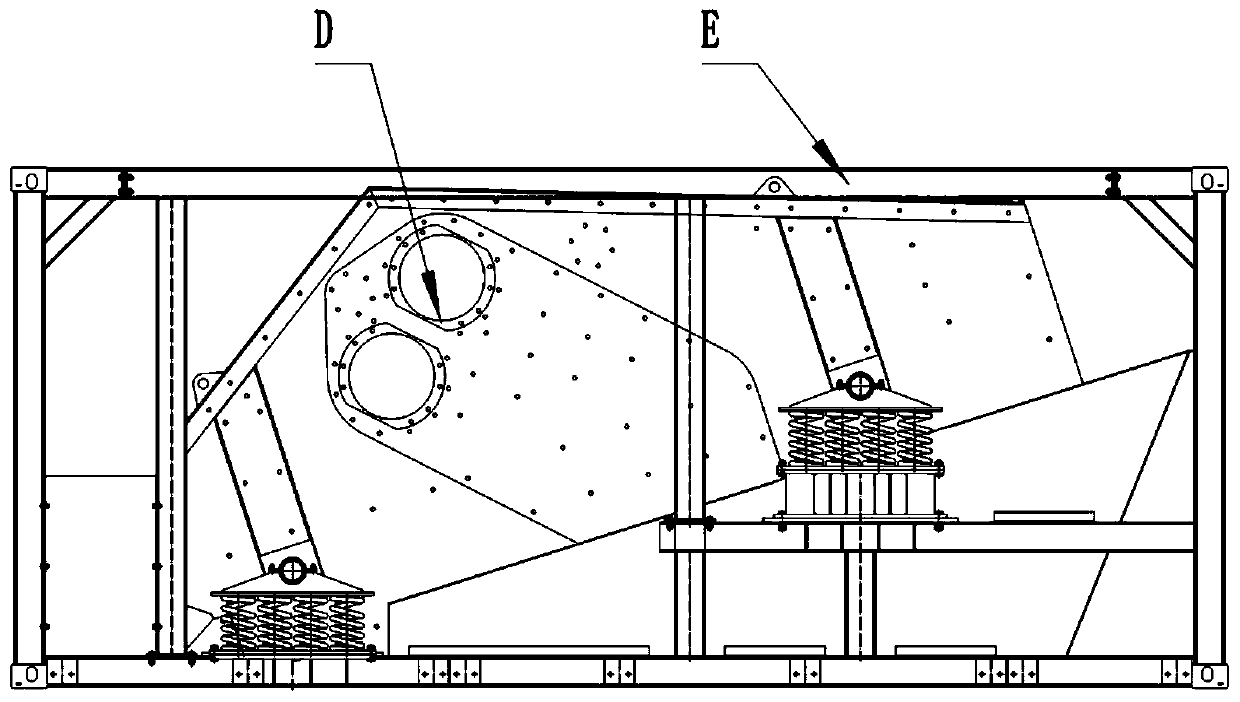

[0058] S2, sieving the sea mud obtained in step S1. The function of sieving treatment is to sieve out large particles of mud or sundries, and improve the uniformity of subsequent mixing of materials. A total of two layers of sieve plates are used for sieving treatment. The first layer of sieve plate has a sieve diameter of 100mm, and the second layer of sieve plate has a sieve hole diameter of 30mm.

[0059] S3, adding polyacrylamide with a volume of 0.2‰ of sea mud to the sea mud obtained in step S2, and dispersing again, until the proportion of sea mud clumps with a diameter l...

Embodiment 2

[0068] The high-viscosity sea mud modification treatment method of the present invention comprises the following steps,

[0069] S1, add polyacrylamide with a volume of 0.3‰ of sea mud to the sea mud and disperse until the sea mud balls with a diameter of less than 30 mm account for ≥90%. The function of the initial dispersion is to disperse the agglomerated sea mud mass and increase its fluidity.

[0070] S2, sieving the sea mud obtained in step S1. A total of two layers of sieve plates are used for sieving treatment. The first layer of sieve plate has a sieve diameter of 100mm, and the second layer of sieve plate has a sieve hole diameter of 30mm.

[0071] S3, adding a polycarboxylate superplasticizer with a sea mud volume of 0.3‰ to the sea mud obtained in step S2, and redispersing until the sea mud clumps with a diameter of less than 5 mm account for ≥95%. The function of redispersing is to disperse the agglomerated sea mud mass and increase its fluidity.

[0072] S4, a...

Embodiment 3

[0080] The high-viscosity sea mud modification treatment method of the present invention comprises the following steps,

[0081] S1, add polyacrylamide with a volume of 0.4‰ of sea mud to the sea mud, and disperse until the sea mud clumps with a diameter of less than 30 mm account for ≥90%. The function of the initial dispersion is to disperse the agglomerated sea mud mass and increase its fluidity.

[0082] S2, sieving the sea mud obtained in step S1. A total of two layers of sieve plates are used for sieving treatment. The first layer of sieve plate has a sieve diameter of 100mm, and the second layer of sieve plate has a sieve hole diameter of 30mm.

[0083] S3, adding sodium hexametaphosphate with a volume of 0.3‰ of sea mud to the sea mud obtained in step S2, and dispersing again until the sea mud clumps with a diameter of less than 5mm account for ≥95%. The function of redispersing is to disperse the agglomerated sea mud mass and increase its fluidity.

[0084] S4, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com