A kind of preparation method of electrostatic spraying polyacetylene particles

A polyacetylene particle, electrostatic spraying technology, applied in the field of electrospinning, can solve problems such as morphology limitation, and achieve the effect of uniform particle size distribution and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

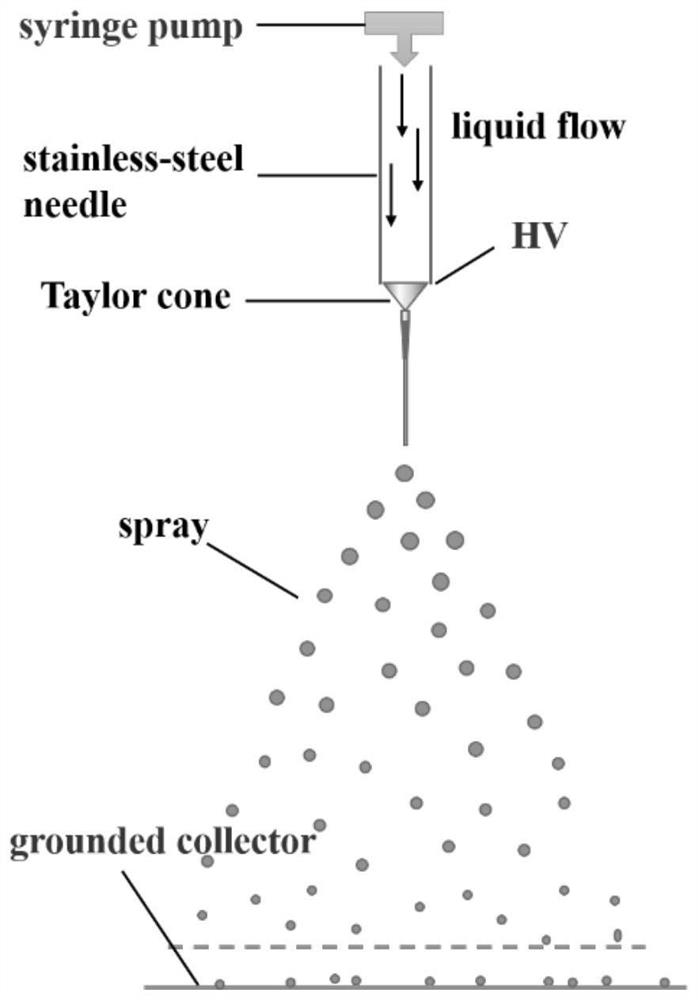

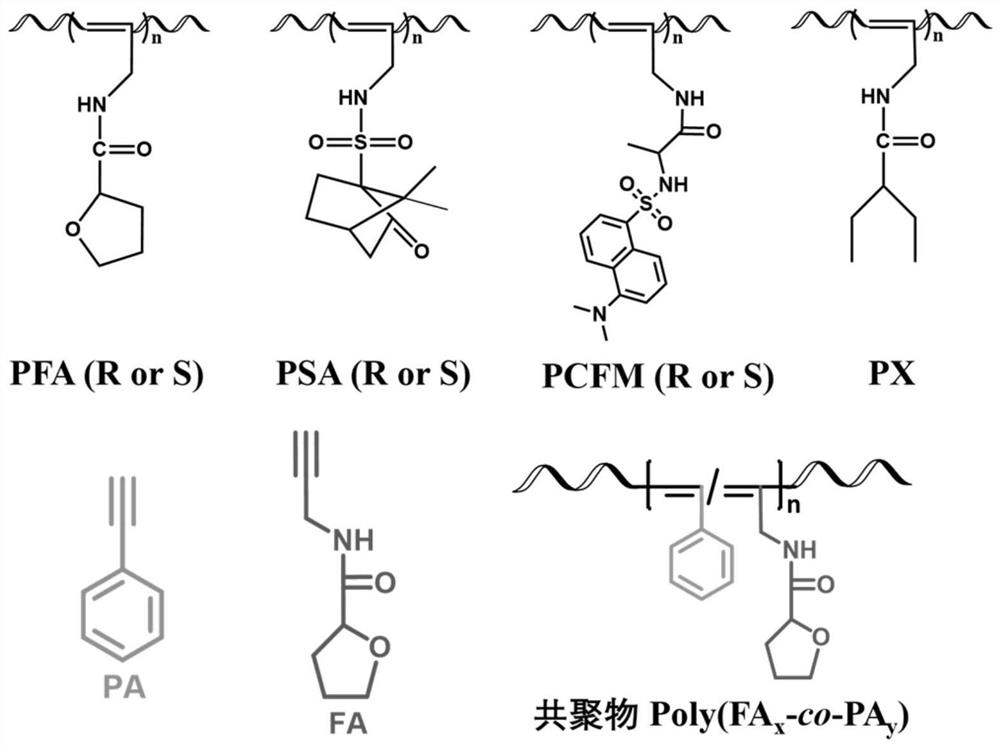

[0033] The preparation method for preparing helical substituted polyacetylene particles of the present invention comprises the following steps:

[0034] Preparation of chiral helical polymers PFA, PSA, PFCM and achiral helical polymers PX, PPA, and copolymers of FA and PA poly(FA x -co-PA y ), the subscripts x, y represent the different molar copolymerization ratios of the respective monomers (x: 2 ~ 8, y: 8 ~ 2), and the blend PFA of PFA and PPA x -b-PPA y , the subscripts x, y represent different blending mass ratios of polymers (x: 2~8, y: 8~2);

[0035] Prepare the electrospray solution of the polymer: respectively dissolve the prepared polymer in the organic solvent, stir until dissolved by magnetic force, and obtain the polymer electrospray solution with different concentrations (10-40wt%);

[0036] Electrostatic spray equipment preparation: mainly including needles, propulsion pumps, receiving boards, high-voltage power supplies, syringes, etc.;

[0037] Preparation...

Embodiment 1

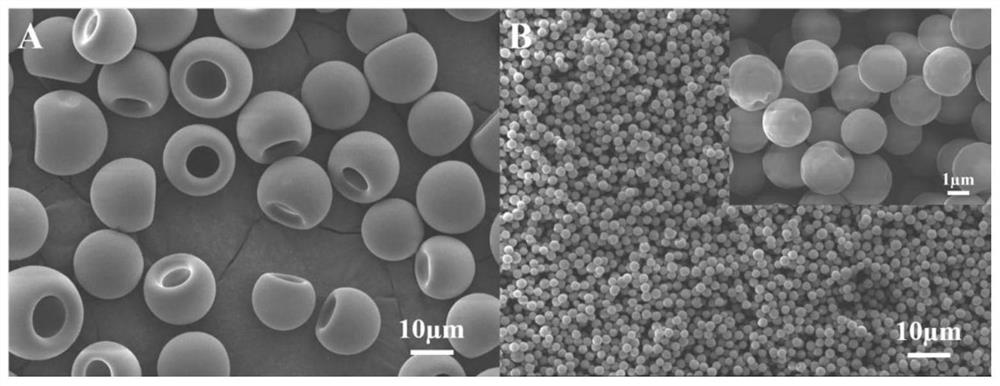

[0040] The embodiment of the present invention provides a method for preparing helically substituted polyacetylene particles by electrostatic spraying method. The specific operation steps include: dissolving 30%wt PFA in an appropriate amount of DMF solvent, and magnetically stirring for a period of time until dissolved to obtain homopolymer-containing Electrospray solution of substances.

[0041] Add the polymer electrospray solution obtained above into the syringe of the electrostatic spray equipment, control the electrospray parameters such as voltage and propulsion speed, and continue to stably electrospray for a period of time to obtain spherical PFA particles. Operating parameters of electrostatic spraying: positive electrode voltage of EFI is 7-9kV, negative electrode voltage of EFI is -2kV, distance from spinneret to receiving plate is 16cm, temperature is 30°C, humidity is 35%, and propulsion speed is 0.004mL / min.

Embodiment 2

[0043] The embodiment of the present invention provides a method for preparing helically substituted polyacetylene particles by electrostatic spraying method. The specific operation steps include: dissolving 20%wt PPA in an appropriate amount of OX solvent, stirring for a period of time until dissolved by magnetic force, and obtaining Electrospray solution of substances.

[0044] Add the polymer electrospray solution obtained above into the syringe of the electrostatic spray equipment, control the electrospray parameters such as voltage and propulsion speed, and continue to stably electrospray for a period of time to obtain non-spherical bowl-shaped PPA particles. Operating parameters of electrostatic spraying: positive electrode voltage of EFI is 7-9kV, negative electrode voltage of EFI is -2kV, distance from spinneret to receiving plate is 16cm, temperature is 30°C, humidity is 35%, and propulsion speed is 0.004mL / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com