Photochromic agricultural greenhouse film and preparation method

An agricultural greenhouse and photochromic technology, applied in botany equipment and methods, applications, agriculture, etc., can solve the problem that the temperature is difficult to meet the ideal color change requirements, and achieve the effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

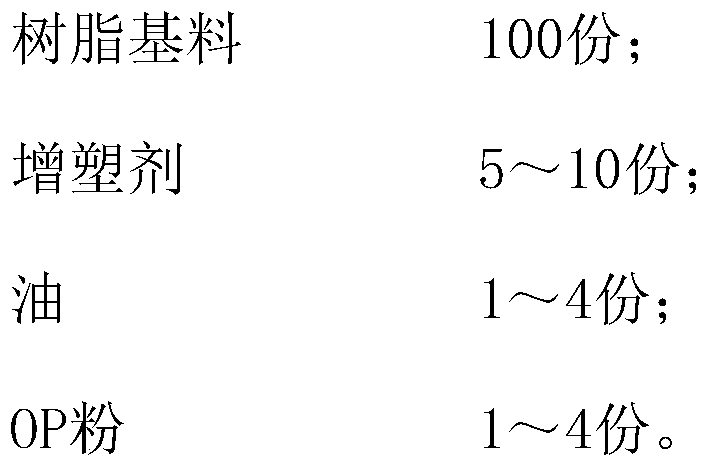

[0020] Example 1: A photochromic agricultural greenhouse film

[0021] Its preparation method is:

[0022] Weigh 100 parts of PVC raw material, 5 parts of plasticizer, 1 part of oil, and 1 part of photochromic compound OP powder. The models of OP powder are OP-099 (rose red), OP-057 (violet), OP-022 (narcissus yellow), and the specific ratio is: 0.3 parts for OP-099, 0.3 parts for OP-057, and 0.3 parts for OP-022 0.4 parts. 2 parts of amine inhibitor 292, mixed evenly, put into the laminator to melt, mixed evenly to form a film, and then put in. After pressing three times, the film is pulled out, the thickness of the film is controlled to be 0.1S-15S (10 μm-150 μm), and the required photochromic film is produced after cooling. The melting temperature of the film is about 170 degrees to 200 degrees. Generally, the melting temperature of EVA film does not exceed 250 degrees. Some photochromic compounds can be filmed at over 250 degrees. The color changing effect is light r...

Embodiment 2

[0023] Example 2: A photochromic agricultural greenhouse film

[0024] Weigh 100 parts of EVA raw material, 8 parts of plasticizer, 3 parts of oil, and 2.5 parts of photochromic compound OP powder. The models of OP powder are OP-099 (rose red), OP-057 (violet), OP-022 (narcissus yellow), and the specific ratio is: 0.2 parts for OP-099, 0.6 parts for OP-057, and 0.6 parts for OP-022 0.2 parts. 3 parts of amine inhibitor 765, mixed evenly, added to the melting machine and calender, pressed three times, and then pulled out the film. The thickness of the control film is 0.1S-15S (10 μm-150 μm), and the required photochromic film is produced after cooling. The melting temperature of the film is about 170 degrees to 200 degrees. Generally, the melting temperature of EVA film does not exceed 250 degrees. Some photochromic compounds can be filmed at over 250 degrees. The discoloration is darker than that of Example 1, which is rose red.

Embodiment 3

[0025] Example 3: A photochromic agricultural greenhouse film

[0026] Weigh 100 parts of PP raw material, 10 parts of plasticizer, 4 parts of oil, and 3.8 parts of photochromic compound OP powder. The models of OP powder are OP-099 (rose red), OP-057 (violet), OP-022 (narcissus yellow), and the specific ratio is: 0.4 parts for OP-099, 0.3 parts for OP-057, and 0.3 parts for OP-022 0.3 parts. 4 parts of hindered amine agent 770, mixed evenly, added to the laminator to melt, mixed evenly, added to the laminator to melt, mixed evenly to form a film, and then put in. After pressing three times, the film is pulled out, the thickness of the film is controlled to be 0.1S-15S (10 μm-150 μm), and the required photochromic film is produced after cooling. The melting temperature of the film is about 170 degrees to 200 degrees. Generally, the melting temperature of EVA film does not exceed 250 degrees. Some photochromic compounds can be filmed at over 250 degrees. The discoloration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com