LCD substrate cleaning agent and using method thereof

A cleaning agent and substrate technology, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, detergent compounding agents, etc., can solve the problems of single cleaning method and sufficient cleaning of unfavorable residues, so as to achieve clean rinsing and avoid substrate display Problems, thorough cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of LCD substrate cleaning agent, formula comprises: Potassium hydroxide, sodium carbonate, ethanolamine, acetone, N-methylpyrrolidone, nonionic surfactant, inorganic flocculant, chelating agent and deionized water, the parts by weight of each component The numbers are: 15 parts of potassium hydroxide, 15 parts of sodium carbonate, 18 parts of ethanolamine, 20 parts of acetone, 15 parts of N-methylpyrrolidone, 8 parts of nonionic surfactant, 8 parts of inorganic flocculation agent, 8 parts of chelating agent and 90 parts of deionized water.

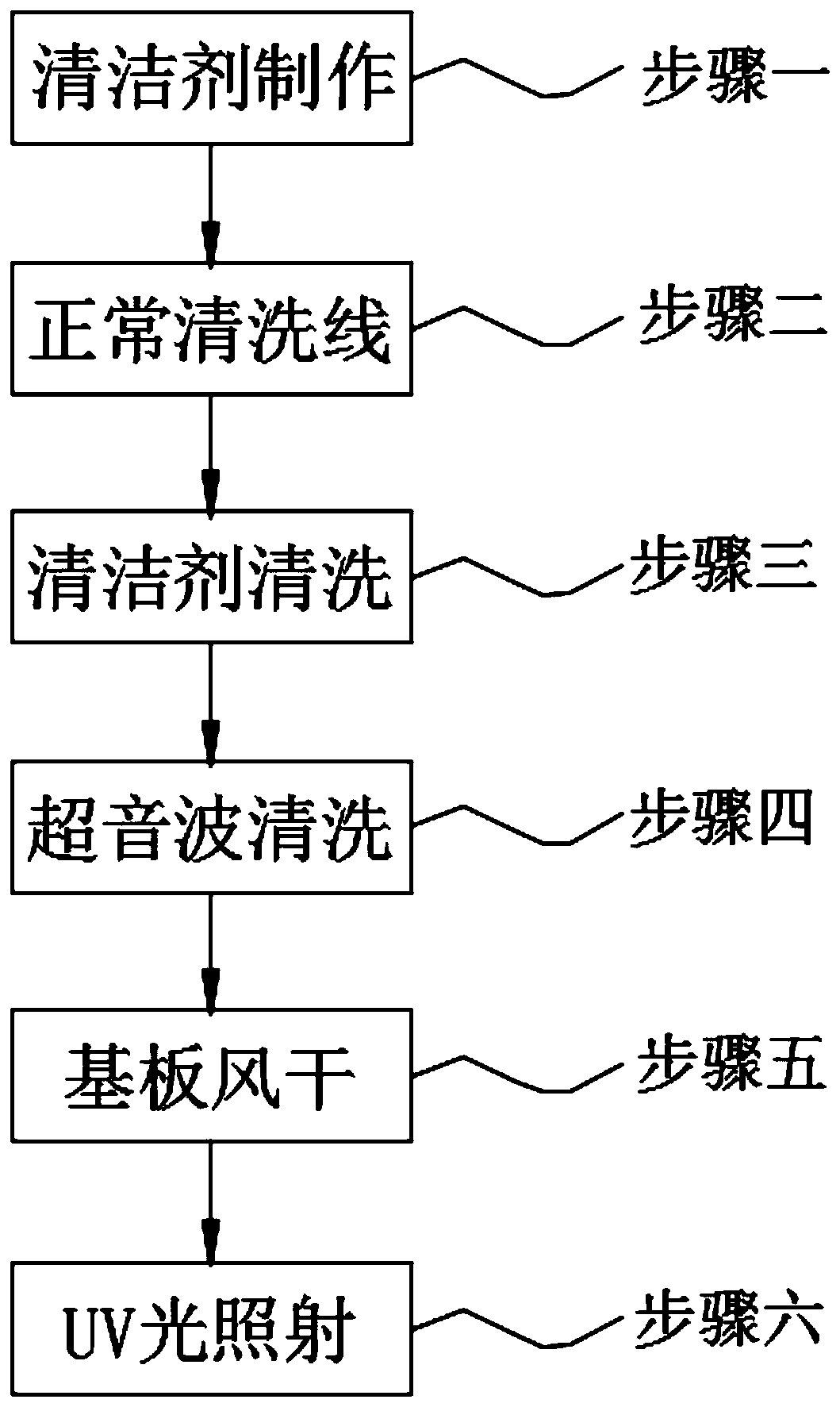

[0029] A method for using an LCD substrate cleaning agent, comprising the following steps: Step 1, cleaning agent production; Step 2, normal cleaning line; Step 3, cleaning agent cleaning; Step 4, ultrasonic cleaning; Step 5, substrate air-drying; Step 6 , UV light irradiation;

[0030] Wherein in above-mentioned step one, cleaning agent production comprises the following steps:

[0031] 1) According to the weight percent o...

Embodiment 2

[0040] A kind of LCD substrate cleaning agent, formula comprises: Potassium hydroxide, sodium carbonate, ethanolamine, acetone, N-methylpyrrolidone, nonionic surfactant, inorganic flocculant, chelating agent and deionized water, the parts by weight of each component The numbers are: 15 parts of potassium hydroxide, 15 parts of sodium carbonate, 18 parts of ethanolamine, 20 parts of acetone, 15 parts of N-methylpyrrolidone, 8 parts of nonionic surfactant, 8 parts of inorganic flocculation agent, 8 parts of chelating agent and 90 parts of deionized water.

[0041] A method for using an LCD substrate cleaning agent, comprising the following steps: Step 1, cleaning agent production; Step 2, normal cleaning line; Step 3, cleaning agent cleaning; Step 4, ultrasonic cleaning; Step 5, substrate air-drying; Step 6 , UV light irradiation;

[0042] Wherein in above-mentioned step one, cleaning agent production comprises the following steps:

[0043] 1) According to the weight percent o...

Embodiment 3

[0052] A kind of LCD substrate cleaning agent, formula comprises: Potassium hydroxide, sodium carbonate, ethanolamine, acetone, N-methylpyrrolidone, nonionic surfactant, inorganic flocculant, chelating agent and deionized water, the parts by weight of each component The numbers are: 15 parts of potassium hydroxide, 15 parts of sodium carbonate, 18 parts of ethanolamine, 20 parts of acetone, 15 parts of N-methylpyrrolidone, 8 parts of nonionic surfactant, 8 parts of inorganic flocculation agent, 8 parts of chelating agent and 90 parts of deionized water.

[0053] A method for using an LCD substrate cleaning agent, comprising the following steps: Step 1, cleaning agent production; Step 2, normal cleaning line; Step 3, cleaning agent cleaning; Step 4, ultrasonic cleaning; Step 5, substrate air-drying; Step 6 , UV light irradiation;

[0054] Wherein in above-mentioned step one, cleaning agent production comprises the following steps:

[0055] 1) According to the weight percent o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com