Degradable solvent-free polyurethane synthetic leather material and preparation method thereof

A solvent-free polyurethane and synthetic leather technology, applied in textiles and papermaking, can solve problems such as easy pollution, adverse effects on product safety, and solvent residues, and achieve low cost, low production cost, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

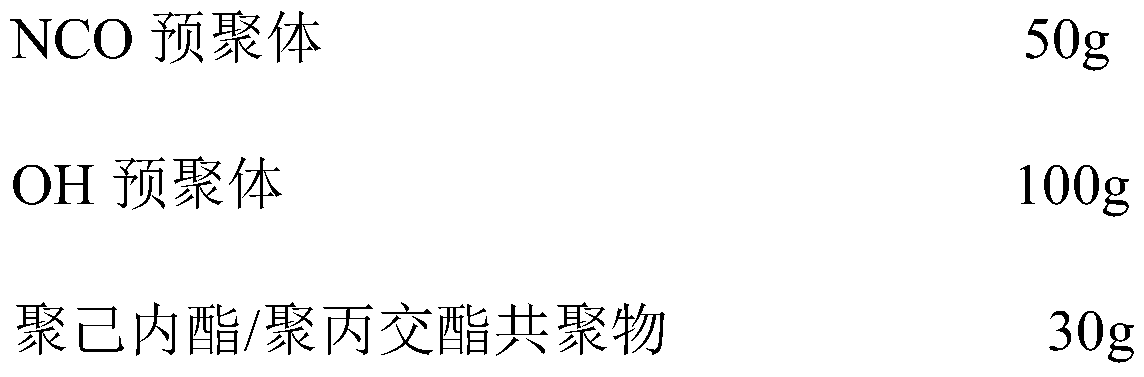

[0040] A kind of easily degradable solvent-free polyurethane synthetic leather material of embodiment 1 of the present invention is made up of each component of following proportioning:

[0041]

[0042]

[0043] 1) Store the low-viscosity and high-molecular-weight NCO prepolymer and the low-viscosity and high-molecular weight OH prepolymer in A and B constant temperature storage tanks respectively according to the weight ratio, and transport them to the mixer according to the weight ratio, and put them into the reaction after mixing fully In the container, put fatty acid triglycerides into the reaction container according to the weight ratio, stir evenly and heat to 120°C for 2 hours for dehydration;

[0044] 2) Cool the mixture to 45°C, add polycaprolactone / polylactide copolymer according to the weight ratio, heat it up to 90°C and keep it warm for 2 hours to fully react;

[0045] 3) Cool the mixture obtained in step 2) to 45°C, add polyethylene glycol according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com