Shield tunneling machine robot tool changing experiment device

An experimental device and robot technology, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve problems such as low accuracy of simulated data and difficulty in tool change of shield machines, achieve high data reliability, reduce tool change risks, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

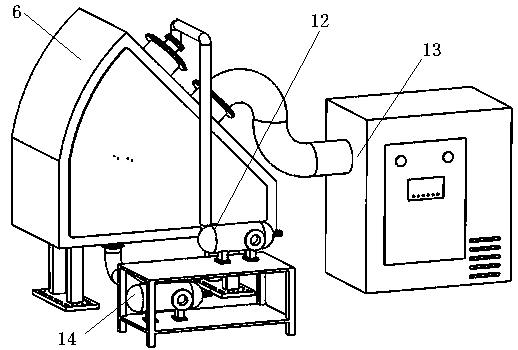

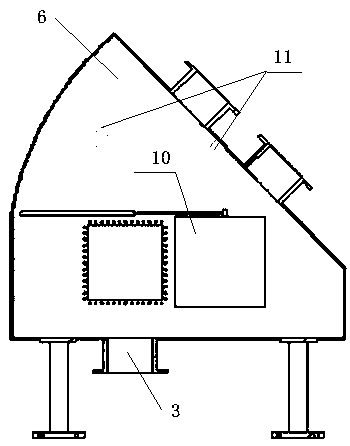

[0025] Example 1, such as figure 1 As shown, a shield machine robot tool change experimental device includes a simulated soil bin 6 and a simulated tool change robot 4, the simulated soil bin 6 is connected with a muddy water filling device 12 and a pressurizing device 13, and the muddy water filling device 12 It is used to add muddy water to the simulated soil silo to simulate the muck environment in the earth silo of the shield machine, the maximum humidity can reach 100%, and the pressurizing device is used to pressurize the simulated soil silo to simulate the inside of the shield machine earth silo In a high-pressure environment, it can be pressurized to 0-30bar, so that the muddy water and pressure are the same as those in the actual soil bin, ensuring the authenticity of the simulated working conditions. The bottom of the simulated soil bin 6 is provided with a sewage discharge device 14, and the sewage discharge device 14 can be used to discharge muddy water in the simu...

Embodiment 2

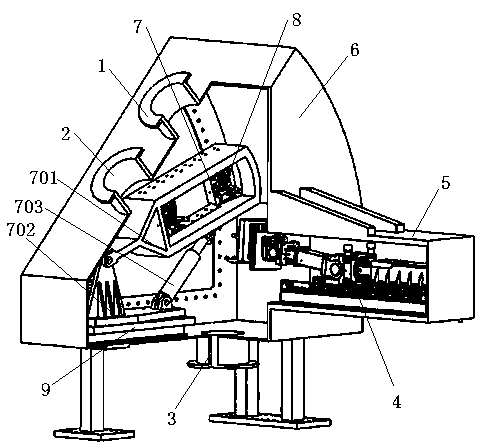

[0029] Example 2, such as Figure 4 As shown, a shield machine robot tool change experimental device, the simulated tool change robot 4 includes a tool change robot body 402, the front end of the tool change robot body 402 is provided with an end effector 401, the end effector 401 is used for Hob replacement. The robot warehouse 5 is provided with a ground rail 403, and the ground rail is fixedly arranged on the inner wall of the lower part of the robot warehouse, and the tool changing robot body 402 is slidingly connected with the ground rail 403, that is, the tool changing robot body can, under the action of the driving mechanism, Slides along floor rails for movement away from or close to the reel assembly.

[0030] Preferably, as Figure 5As shown, the tool changing robot body 402 includes a first support arm 402-1 and a second support arm 402-5, and a first telescopic arm 402-2 is slid inside the first support arm 402-1, that is, the first telescopic arm 402-2 is The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com