Efficient energy-saving environment-friendly calcium carbide furnace

A high-efficiency, energy-saving, and environment-friendly technology, applied in the drying of solid materials, dryers, and drying of granular materials, can solve the problems of equipment cleanliness reduction, resource waste, and impact, and achieve the effect of calcium carbide quality assurance and reduction of raw material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

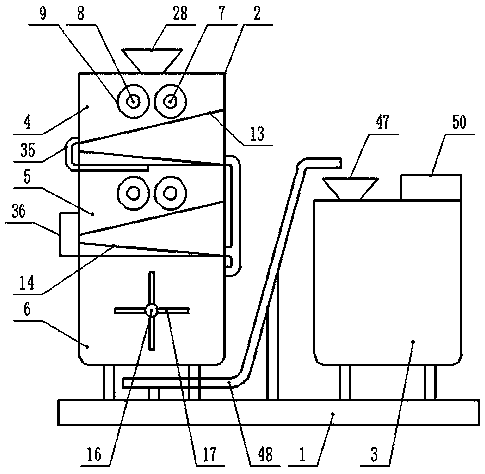

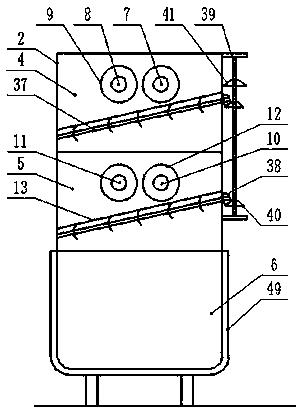

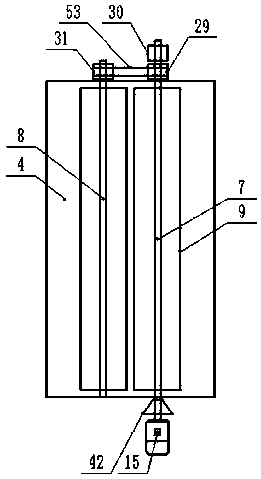

[0017] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , a high-efficiency, energy-saving and environment-friendly calcium carbide furnace provided by the present invention is now described, including a machine base 1, the upper end of the machine base 1 is provided with a material preparation box 2 and a furnace body 3, and the material preparation box 2 is provided with a partition And the interlayer divides the inner cavity of the material preparation box 2 from top to bottom into the first grinding cavity 4, the second grinding cavity 5 and the mixing drying cavity 6, and the upper end of the first grinding cavity 4 is The first driving shaft 7 and the first driven shaft 8 are arranged in parallel at intervals on the side, and the first grinding roller sleeves are respectively set in the first grinding chamber 4 and outside the first driving shaft 7 and the first driven shaft 8. 9. A second driving shaft 10 and a second driven sha...

Embodiment 2

[0018] Example 2: see figure 1 , figure 2 , image 3 , Figure 4 , a high-efficiency, energy-saving and environment-friendly calcium carbide furnace provided by the present invention will now be described. Supporting columns are evenly arranged between the bottom of the material preparation box 2, the furnace body 3, and the upper end of the machine base 1. The material preparation box 2. There is a feeding opening on the middle side of the top and along its length direction. The outer top of the material preparation box 2 is provided with a feeding hopper 28 corresponding to the position of the feeding opening. The first driving shaft 7 and the first driven shaft 8, The second driving shaft 10 and the second driven shaft 11 are respectively arranged along the length direction of the first grinding chamber 4 and the inner cavity of the second grinding chamber 5, and both ends of the first driving shaft 7 in the length direction are respectively movable through The inner en...

Embodiment 3

[0019] Embodiment 3: see figure 1 , figure 2 , image 3 , a high-efficiency, energy-saving and environment-friendly calcium carbide furnace provided by the present invention is now described. In the first grinding chamber 4 and the second grinding chamber 5, a rotating shaft 37 is respectively arranged below the position close to the inclined screen 13. The rotating shaft 37 is arranged in parallel with the inclined screen 13 at intervals, and the upper ends in the inclined direction of the rotating shaft 37 are respectively movable and extend through the inner end wall of the storage box 2, and the protruding ends are respectively covered with fourth Transmission gear 38, the position of the fourth transmission gear 38 is vertically provided with a transmission shaft 39, the outside of the transmission shaft 39 and the position corresponding to the fourth transmission gear 38 are respectively covered with a third transmission gear 40, the transmission shaft 39 The top is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com