A detection device and detection method for quickly detecting and identifying surface defects of an optical element

A technology of optical components and identification devices, applied in the field of defect detection, can solve problems such as the inability to quickly detect the surface of large-diameter components, the inability to distinguish defect types, and provide guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

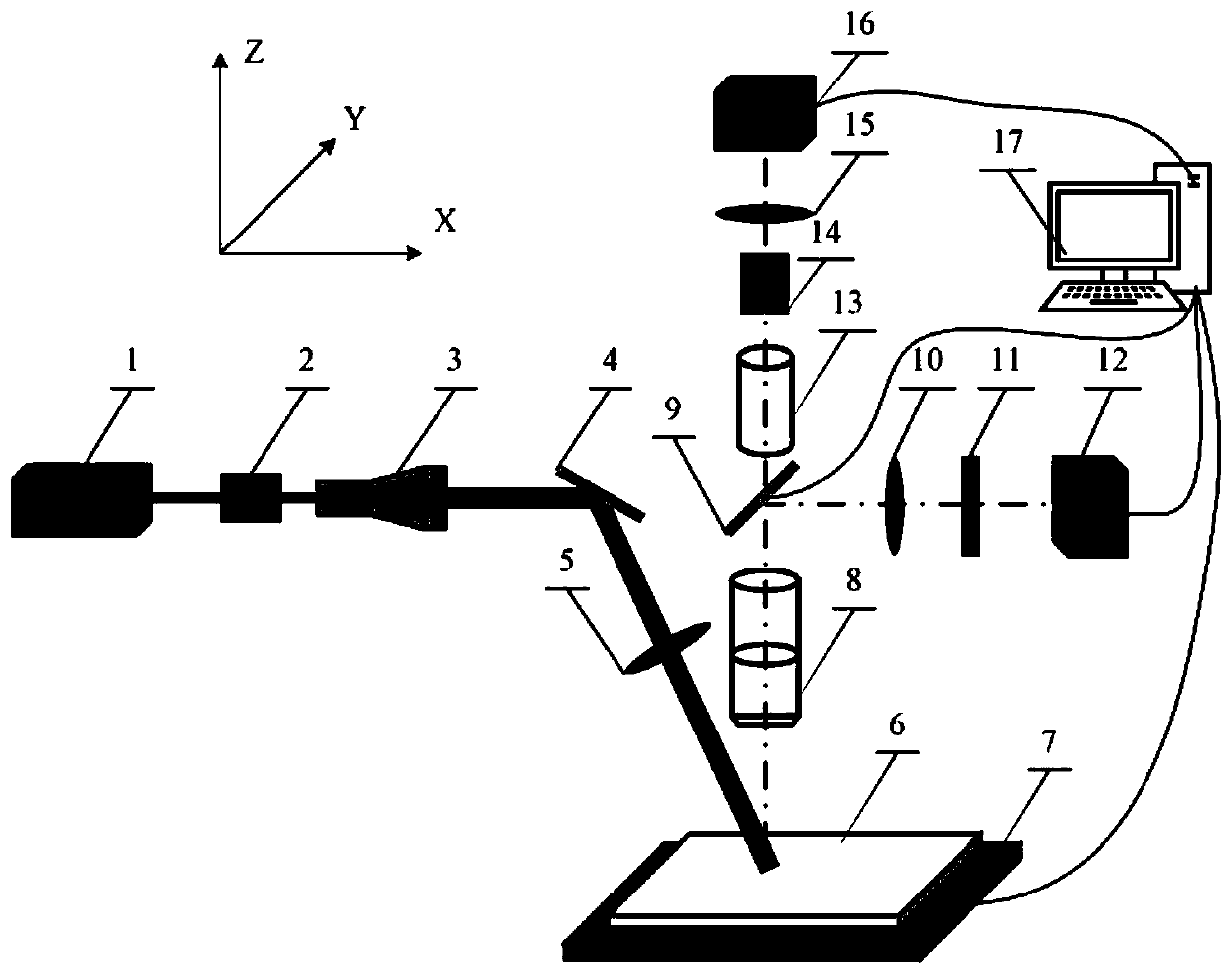

[0027] figure 1 It is a schematic diagram of the rapid detection and identification device for surface defects of optical components of the present invention. It can be seen from the figure that the rapid detection and recognition device of optical components surface defects of the present invention includes a laser 1, a beam shaper 2, a beam expander 3, a mirror 4, and a converging lens 5. Sample 6, XY precision displacement platform 7, zoom lens 8, electric optical path switcher 9, first imaging lens 10, long-wave pass filter 11, first area array photodetector 12, collimator 13, Tuning filter 14, second imaging lens 15, second area array photodetector 16 and computer 17;

[0028] The sample 6 is placed on the XY precision displacement platform 7, and the electric optical path switcher 9 is composed of a reflector installed on an electric flip mount, and the reflective surface of the reflector is perpendicular to the xz plane, The electric flip mounting base can rotate the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com