Steel slag powder artificial fish reef material and preparation method thereof

A technology of artificial fish reefs and steel slag powder, applied in clay preparation devices, chemical instruments and methods, manufacturing tools, etc., to achieve the effects of low cost, simple process, and improved biological aggregation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

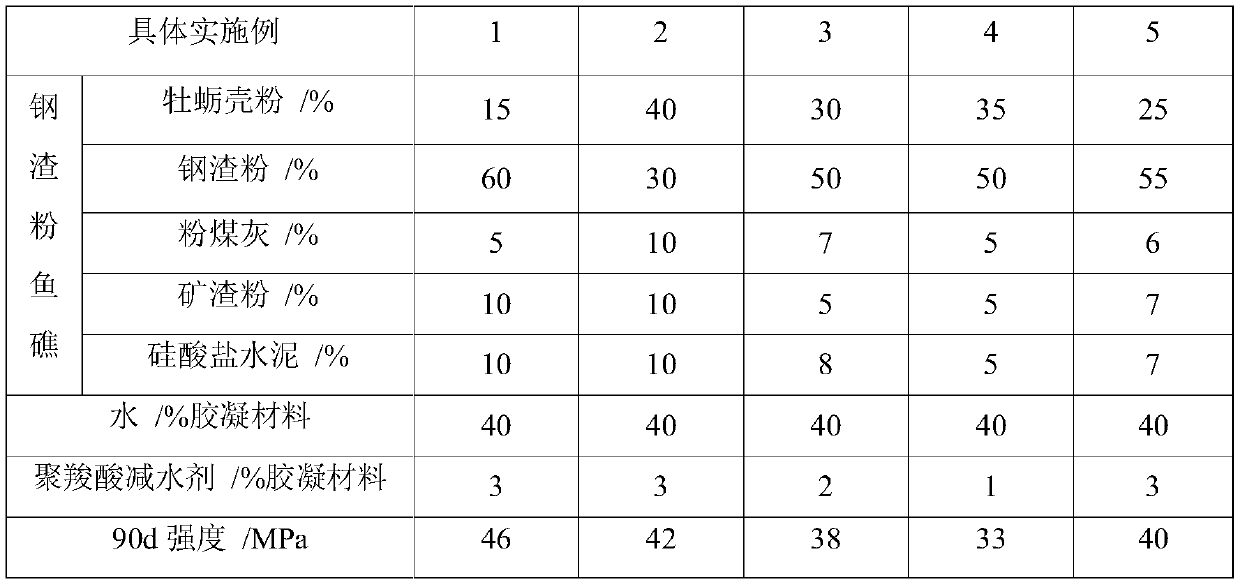

[0022] The steel slag powder artificial fish reef material provided in the present invention has the following mass percentage relationship of the raw material formula: oyster shell powder 15-40%; steel slag powder 30-60%; fly ash 5-10%; slag powder 5-10% ; Portland cement 5-10%.

[0023] Among them, oyster shell powder is obtained from natural oyster shells by drying, crushing, and screening, and the particle size of the powder is between 1mm and 5mm; steel slag powder is obtained from steel slag through magnetic separation, grinding, and powder selection, and the specific surface area is between 1mm and 5mm. 300~500m 2 Between / kg; CaO content in fly ash exceeds 10%, fineness ≤ secondary ash; slag powder is granulated blast furnace slag powder, activity index ≥ S75 grade ash; Portland cement is silicic acid of grade 42.5 and above salt cement.

[0024] The preparation method of the steel slag powder artificial fish reef material comprises the following steps:

[0025] (1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com