Ceramic 3D printing paste and preparation method thereof

A 3D printing and ceramic technology, applied in the field of 3D printing, can solve the problems of difficult processing and hinder the development of ceramic materials, and achieve the effect of good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

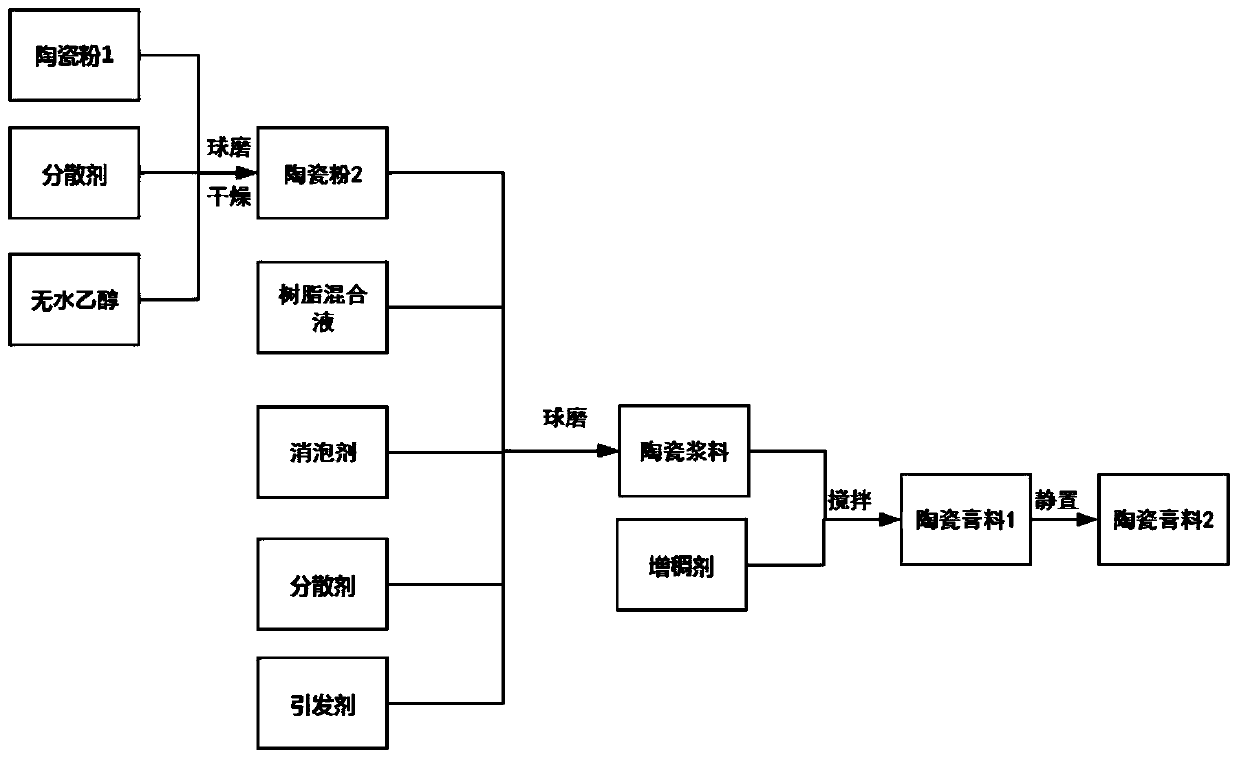

[0038] The preparation method of this embodiment includes step S1 to step S3.

[0039] Step S1, performing pretreatment on the ceramic powder to obtain pretreated ceramic powder.

[0040] Use absolute ethanol and dispersant to ceramic powder figure 1 The ceramic powder 1 in the ceramic powder is processed, specifically, the ceramic powder can be processed with 40% to 60% absolute ethanol and a dispersant whose quality is 0.5% to 2.5% of the ceramic powder quality. processed, collected after drying, and obtained the pre-treated ceramic powder that is figure 1 Ceramic powder in 2.

[0041] Step S2, adding the pretreated ceramic powder into the prepared mixed solution of photosensitive resin, dispersant, defoamer and photoinitiator, and ball milling to prepare slurry.

[0042] In this embodiment, the photosensitive resin is a mixture of three resin monomers. The slurry obtained by ball milling is ceramic slurry.

[0043]Step S3, adding a thickener to the obtained slurry, sti...

experiment example 1

[0047] Weigh 75g of IBOA, 150g of HDDA and 75g of TMPTA (13.03% of the total mass), place the photosensitive resin in a 1L ball mill jar with 1kg of ground zirconium balls, then add 36.85g of dispersant BYK- 110 (for ZrO 2 2% of powder mass), 11.52g of defoamer BYK-088 (0.5% of total mass) and 1.5g of photoinitiator 184 (0.5% of photosensitive resin mass), ball milling 160r / min, ball milling 0.5h . After each component is completely dissolved, add 1861g (ZrO 2 Solid content is 80%) ZrO through powder pretreatment 2 Powder. After ball milling at 180r / min for 20h, ZrO was collected 2 ceramic slurry. Then add 92.12g of thickener BYK-415 (4% of the total mass) thereto, stir at high speed for 1h, and then stand still for 10h to obtain a ceramic paste.

experiment example 2

[0049] Weigh 75g of IBOA, 150g of HDDA and 75g of TMPTA (10.95% of the total mass), place the photosensitive resin in a 1L ball mill jar with 1kg of ground zirconium balls, then add 45.47g of dispersant BYK- 110 (ZrO 2 2% of powder mass), 13.7g of defoamer BYK-088 (0.5% of total mass) and 1.2g of photoinitiator 184 (0.4% of photosensitive resin mass), ball milling 160r / min, ball milling 0.5h. After each component is completely dissolved, add 2296g (ZrO 2 Solid content is 83%) ZrO through powder pretreatment 2 Powder. After ball milling at 180r / min for 20h, ZrO was collected 2 ceramic slurry. Then add 82.17g of thickener BYK-415 (3% of the total mass) thereto, stir at a high speed for 1 hour, and then stand still for 10 hours to obtain a ceramic paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com