A kind of production method of expanded ammonium nitrate explosive

A technology of expanded ammonium nitrate explosives and production methods, which is applied in the direction of explosives, explosive composite components, explosive processing equipment, etc., and can solve problems such as easy mixing of water phase and oil phase, incomplete expansion, unstable product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

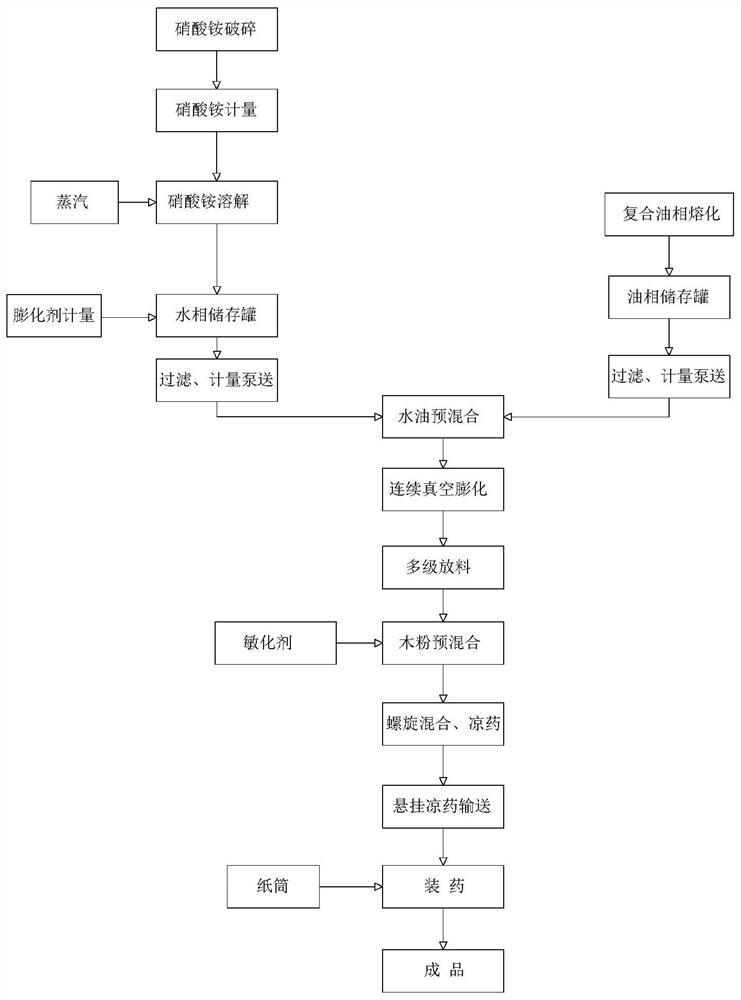

[0037] Such as figure 1 As shown, the present embodiment provides a kind of production method of expanded ammonium nitrate explosive, comprises the following processing steps:

[0038] S1. Preparation of water phase: After the ammonium nitrate is transported by the tanker, the ammonium nitrate is crushed by the crusher. After the crushed ammonium nitrate is measured, it is added to the dissolving tank, and steam is introduced into the dissolving tank, so that the ammonium nitrate is heated and dissolved in the steam In the condensed water, a liquid ammonium nitrate solution is obtained, and the liquid ammonium nitrate solution is transported to the water phase storage tank through the pump body. 0.25% of the total mass of the liquid ammonium nitrate solution in the phase storage tank is used to measure the expansion agent, and then add it to the water phase storage tank, so that the expansion agent is dissolved in the ammonium nitrate solution to obtain an aqueous phase liquid...

Embodiment 2

[0045] Such as figure 1 As shown, the present embodiment provides a kind of production method of expanded ammonium nitrate explosive, comprises the following processing steps:

[0046] S1. Preparation of water phase: After the ammonium nitrate is transported by the tanker, the ammonium nitrate is crushed by the crusher. After the crushed ammonium nitrate is measured, it is added to the dissolving tank, and steam is introduced into the dissolving tank, so that the ammonium nitrate is heated and dissolved in the steam In the condensed water, a liquid ammonium nitrate solution is obtained, and the liquid ammonium nitrate solution is transported to the water phase storage tank through the pump body. 0.27% of the total mass of the liquid ammonium nitrate solution in the phase storage tank is used to measure the expansion agent, and then add it to the water phase storage tank, so that the expansion agent is dissolved in the ammonium nitrate solution to obtain an aqueous phase liquid...

Embodiment 3

[0053] Such as figure 1 As shown, the present embodiment provides a kind of production method of expanded ammonium nitrate explosive, comprises the following processing steps:

[0054] S1. Preparation of water phase: After the ammonium nitrate is transported by the tanker, the ammonium nitrate is crushed by the crusher. After the crushed ammonium nitrate is measured, it is added to the dissolving tank, and steam is introduced into the dissolving tank, so that the ammonium nitrate is heated and dissolved in the steam In the condensed water, a liquid ammonium nitrate solution is obtained, and the liquid ammonium nitrate solution is transported to the water phase storage tank through the pump body. 0.3% of the total mass of the liquid ammonium nitrate solution in the phase storage tank is used to measure the expansion agent, and then add it to the water phase storage tank, so that the expansion agent is dissolved in the ammonium nitrate solution to obtain an aqueous phase liquid....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com