Preparation method for mu-conotoxin

A technology of cone snail and wrinkle, which is applied in the field of polypeptide product preparation, can solve the problems of high extraction cost and low biological content, and achieve the effects of high total yield, high purity of pure products and short synthesis cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

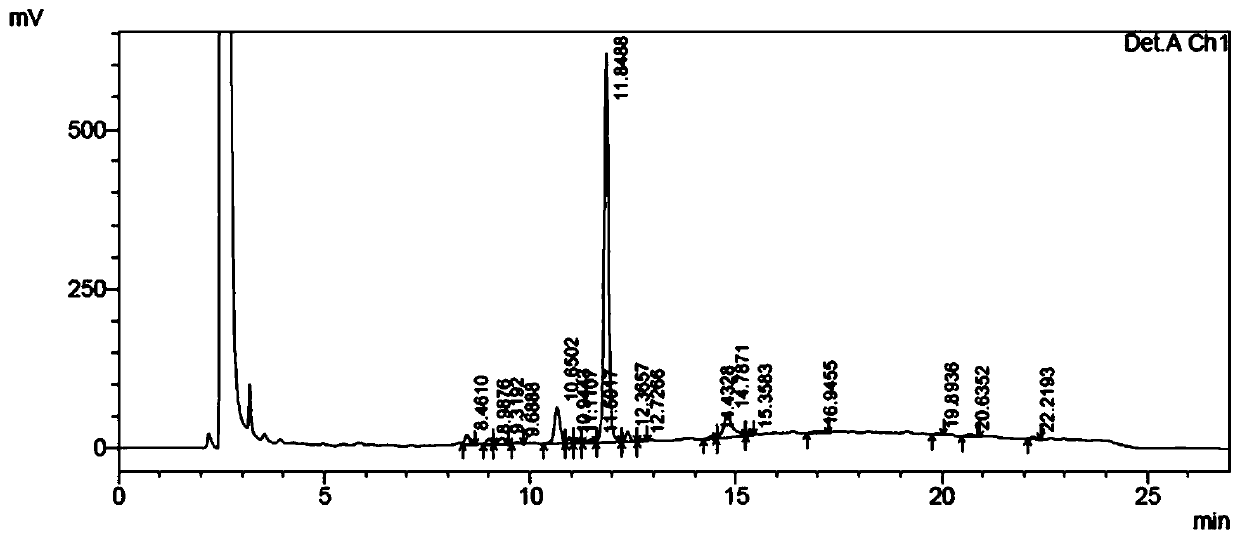

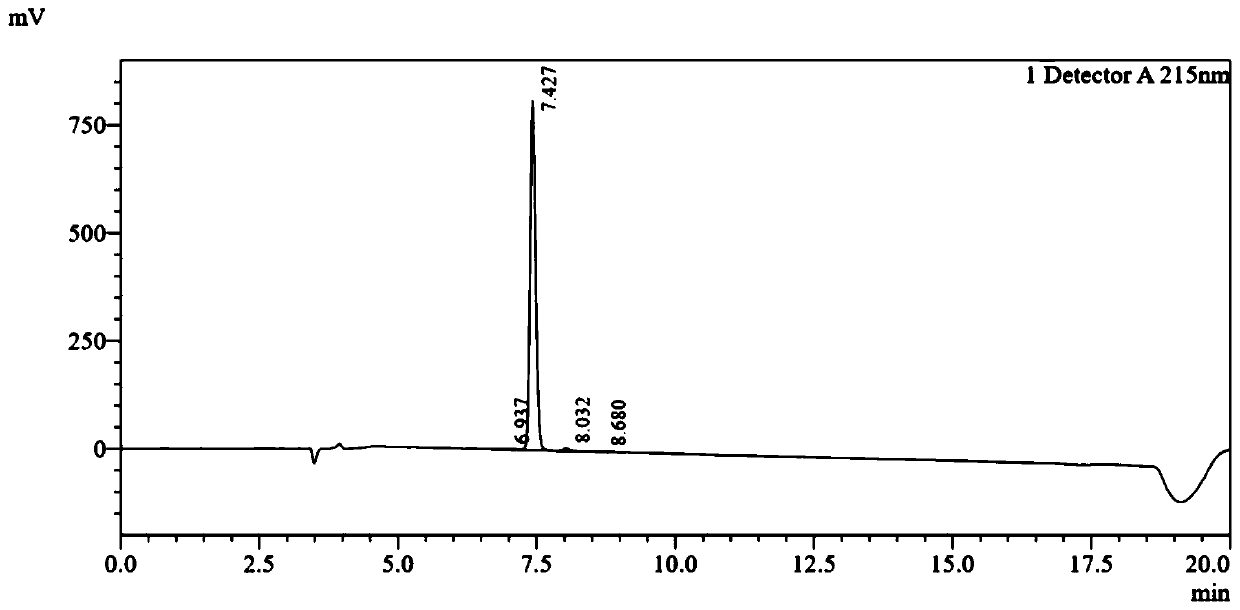

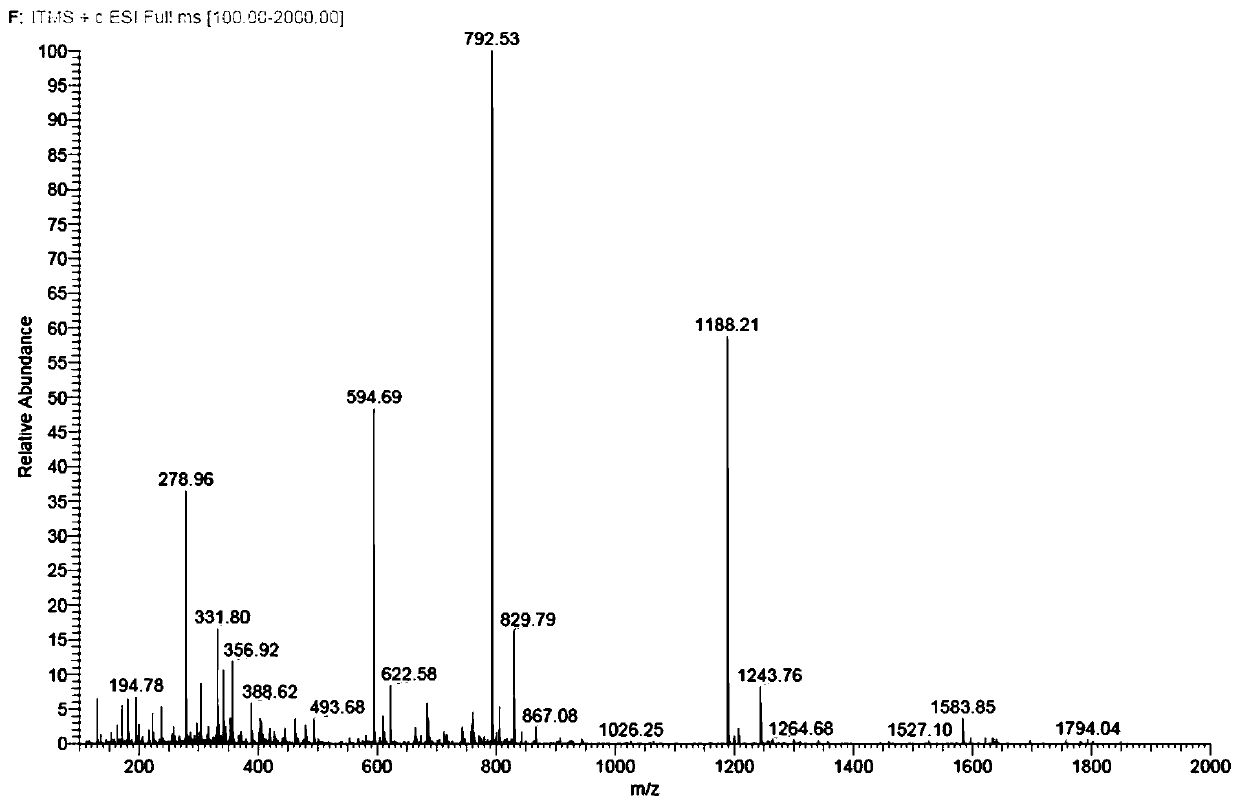

Image

Examples

Embodiment 1

[0029] Example 1: Coupling of Fmoc-Cys(Trt)-OH (22nd amino acid)

[0030] Weigh Rink Amide AM Resin (100.00g, loading: 0.6mmol / g) and wash it once with 1000mL dry DMF, drain it, swell in 1000mL DMF for 2 h, and drain it.

[0031] Add 20% piperidine / DMF solution (DBLK solution) for deprotection twice, 1000mL / time, 5min+15min. After the deprotection is completed, wash with DMF 6 times, 1000 mL / time / min, drain, and detect ninhydrin, K+.

[0032] Weigh 70.29 g Fmoc-Cys(Trt)-OH, dissolve 17.84 g HOBt in 1000 mL DMF, add 16.67 g DIC under ice cooling to activate the solution for about 5 min, pour it into the reaction column, stir the reaction at room temperature for 2 h, and take a sample , ninhydrin detection, K-; wash the resin 3 times with DMF, 1000 mL / time / min, and drain.

Embodiment 2

[0033] Example 2: Coupling of Fmoc-Cys(Trt)-OH (21st amino acid)

[0034] Add 20% piperidine / DMF solution (DBLK solution) for deprotection twice, 1000mL / time, 5min+15min. After the deprotection is completed, wash with DMF 6 times, 1000 mL / time / min, drain, and detect ninhydrin, K+.

[0035] Weigh 70.29 g Fmoc-Cys(Trt)-OH, dissolve 17.84 g HOBt in 1000 mL DMF, add 16.67 g DIC under ice cooling to activate the solution for about 5 min, pour it into the reaction column, stir the reaction at room temperature for 2 h, and take a sample , ninhydrin detection, K-; wash the resin 3 times with DMF, 1000 mL / time / min, and drain.

Embodiment 3

[0036] Example 3: Coupling of Fmoc-Arg(Pbf)-OH (20th amino acid)

[0037] Add 20% piperidine / DMF solution (DBLK solution) for deprotection twice, 1000mL / time, 5min+15min. After the deprotection is completed, wash with DMF 6 times, 1000 mL / time / min, drain, and detect ninhydrin, K+.

[0038]Weigh 63.15 g Fmoc-Arg(Pbf)-OH, dissolve 17.84 g HOBt in 1000 mL DMF, add 16.67 g DIC under ice cooling to activate the solution for about 5 min, pour it into the reaction column, stir the reaction at room temperature for 2 h, and take a sample , ninhydrin detection, K-; wash the resin 3 times with DMF, 1000 mL / time / min, and drain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com