Preparation method of chitosan preservative film

A technology of chitosan and plastic wrap, which is applied in the field of preparation of chitosan plastic wrap, can solve the problems of poor water resistance of plastic wrap, and achieve the effects of reduced water permeability, good biocompatibility, and long-term food preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

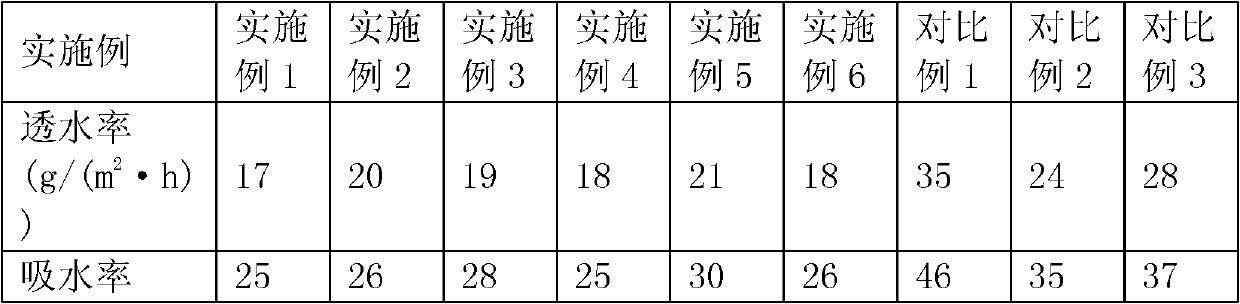

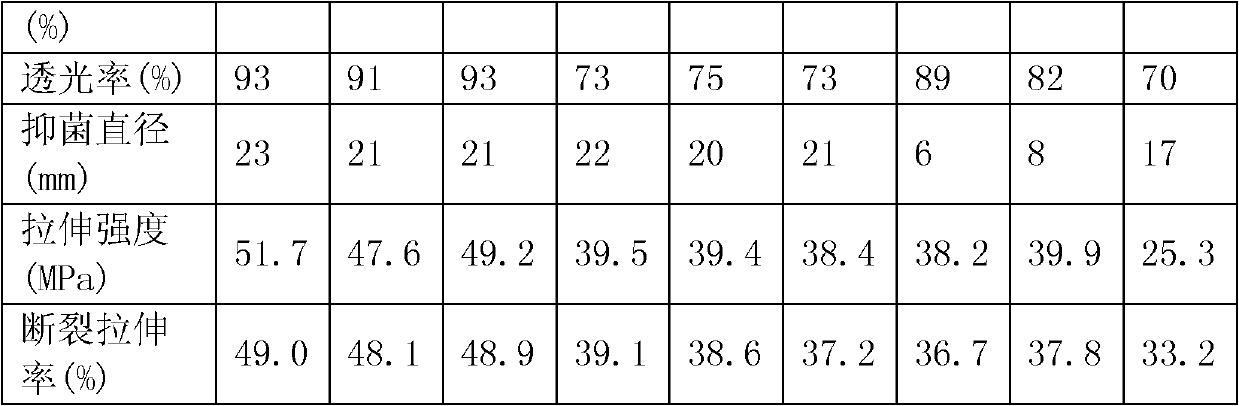

Examples

Embodiment 1

[0023] (1) Dissolve 0.05 mol of chitosan with a deacetylation degree of 85% in 500 mL of acetic acid solution with a volume fraction of 1%, add 0.05 mol of arabinose while stirring, react at 80 °C for 3 h, and cool to room temperature , to obtain product A;

[0024] (2) Mix 40 g of product A, 5 g of palm oil, 1 g of alkyl polyglucoside, 5 g of gum arabic and 20 g of modified starch to form mixture B. Speed shear dispersion for 20 min, then add 0.1 g polydimethylsiloxane, degas under reduced pressure at 0.1 MPa for 1 h, then stir at 300 r / min for 60 min to obtain product C;

[0025] (3) After natural cooling, the product C is evenly coated on an acrylic plate, and dried at 50 ℃ to form a film to obtain the product.

Embodiment 2

[0027] (1) Dissolve 0.05 mol of chitosan with a deacetylation degree of 85% in 200 mL of acetic acid solution with a volume fraction of 2%, add 0.1 mol of arabinose while stirring, react at 100 °C for 2 h, and cool to room temperature , to obtain product A;

[0028] (2) Mix 50 g of product A, 10 g of palm oil, 2 g of alkyl polyglucoside, 10 g of gum arabic and 15 g of modified starch to form mixture B. Speed shear dispersion for 5 min, then add 0.3 g of polydimethylsiloxane, degas under reduced pressure at 0.1 MPa for 2 h, then stir at 400 r / min for 40 min to obtain product C;

[0029] (3) After natural cooling, the product C is evenly coated on an acrylic plate, and dried at 60 ℃ to form a film to obtain the product.

Embodiment 3

[0031] (1) Dissolve 0.05 mol of chitosan with a deacetylation degree of 92% in 100 mL of acetic acid solution with a volume fraction of 3%, add 0.15 mol of arabinose while stirring, react at 120 °C for 1 h, and cool to room temperature , to obtain product A;

[0032] (2) Mix 60 g of product A, 15 g of palm oil, 3 g of alkyl polyglucoside, 8 g of gum arabic and 10 g of modified starch to form mixture B. Speed shear dispersion for 10 min, then add 0.2 g of polydimethylsiloxane, degas under reduced pressure at 0.1 MPa for 1.5 h, then stir at 600 r / min for 30 min to obtain product C;

[0033] (3) After natural cooling, the product C is evenly coated on an acrylic plate, and dried at 55 ℃ to form a film to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com