Production technology of nanometer modified polyolefin resin film

A polyolefin resin and production process technology, applied in the field of nano-material modified polyolefin resin film, can solve the problems of poor barrier performance, high oxygen transmission rate, insufficient material rigidity, etc., to prolong shelf life and improve barrier performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

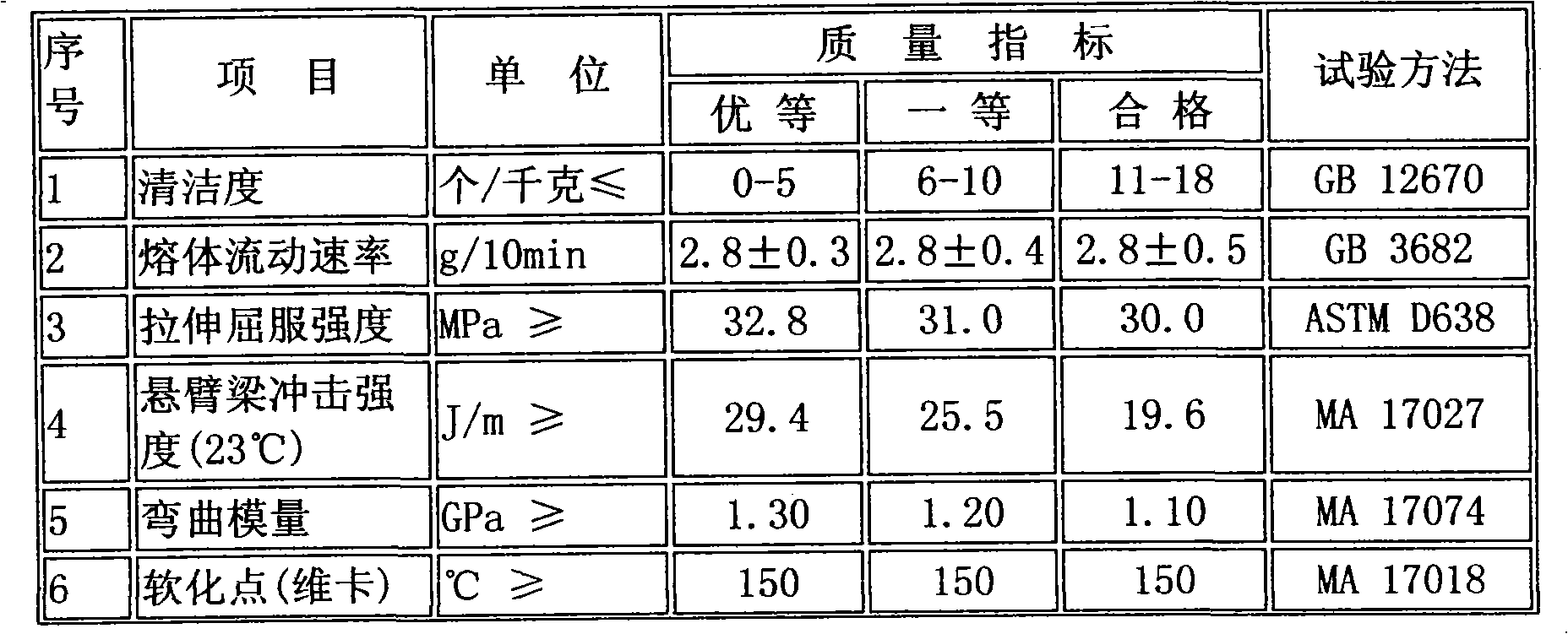

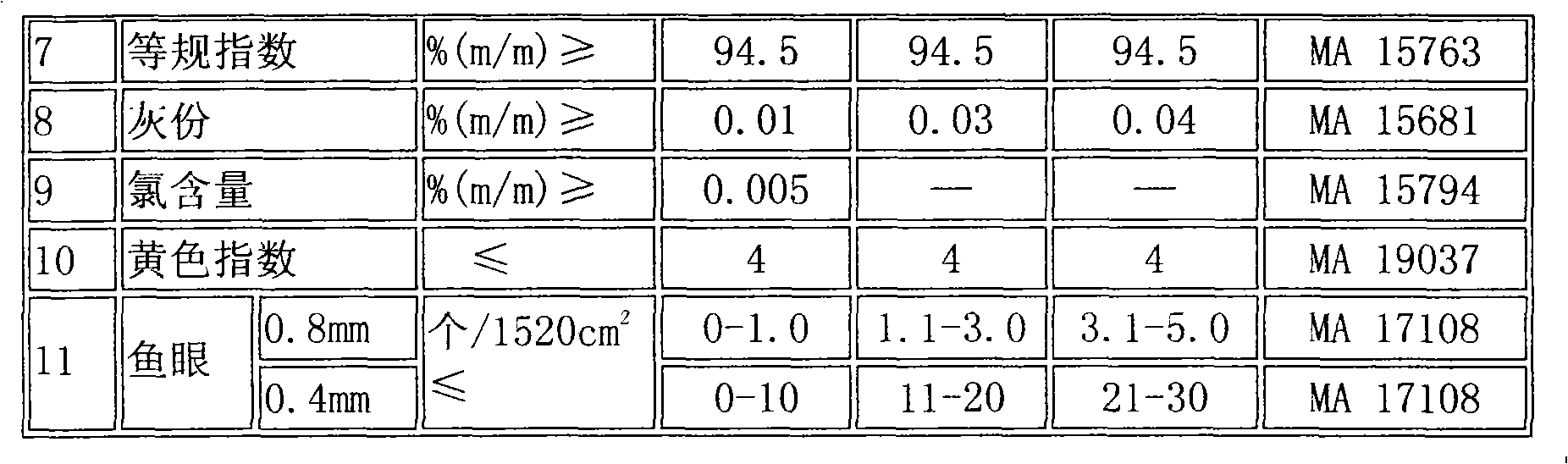

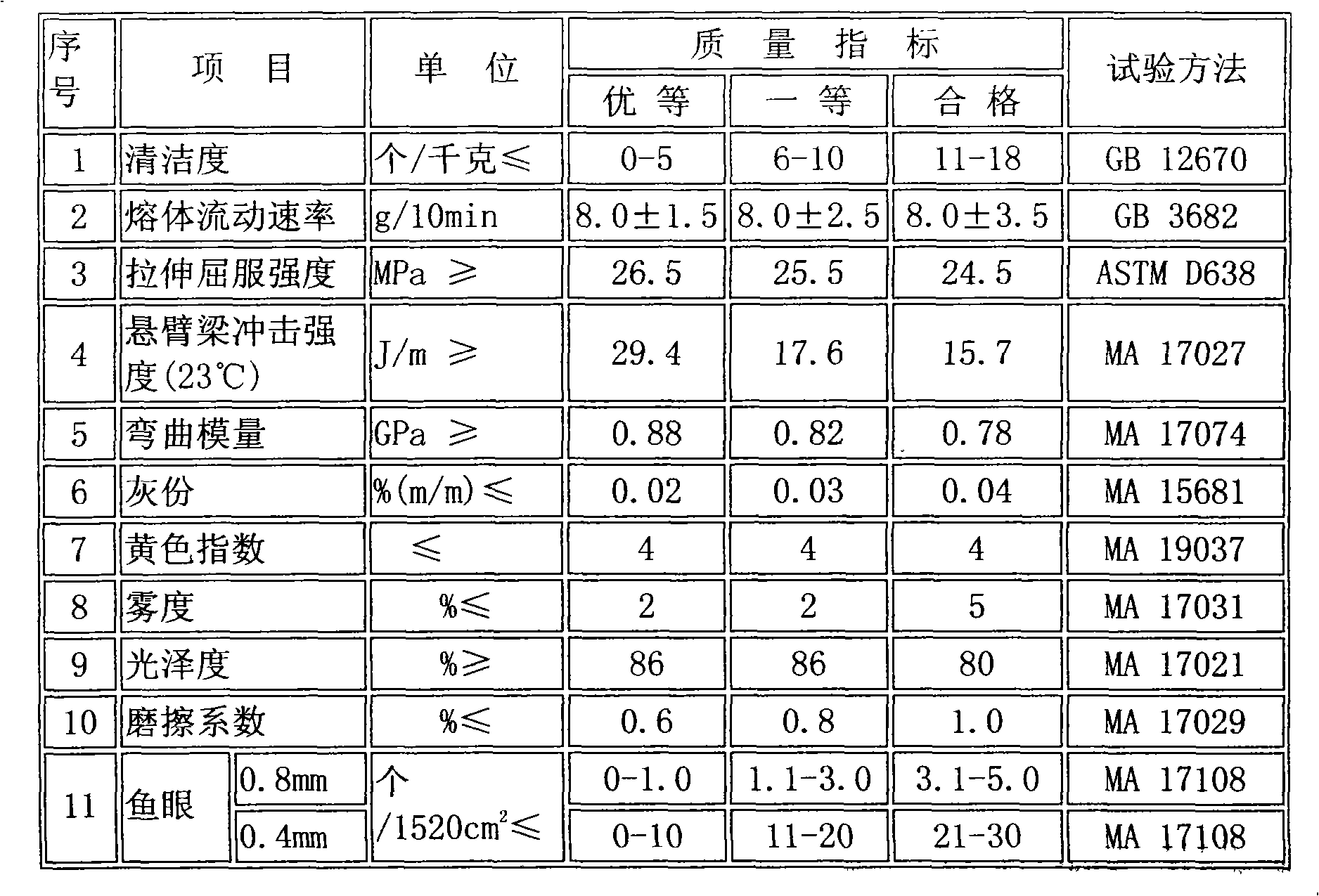

Image

Examples

Embodiment 1

[0019] The production process of a kind of unstretched nano-material modified polyolefin resin film (CPP) of the present embodiment, this process comprises 1) the preparation of modified nano silicon dioxide, the preparation of modified nano silicon dioxide adopts particle size = 50nm nano-SiO 2 Particles and titanate coupling agent NDZ-101, first dissolve the weighed isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate coupling agent with xylene solvent, and then mix with nano-SiO 2 The particles were thoroughly mixed until uniform, and put into an oven to dry to remove the solvent, wherein the drying temperature was 110° C., and the drying time was 2 hours. The addition of titanate coupling agent is nano-SiO 2 5% by weight of particles.

[0020] 2) The preparation of modified nano-montmorillonite uses nano-montmorillonite particles with a particle size of 50nm and a titanate coupling agent NDZ-101. First, the weighed titanate coupling agent is dissolved in ...

Embodiment 2

[0024] A kind of production technology of biaxially stretched nanomaterial modified polyolefin resin film (BOPP) of the present embodiment, this technology comprises 1) the preparation of modified nano silicon dioxide, the preparation of modified nano silicon dioxide adopts particle diameter = 50nm nano-SiO 2 Particles and titanate coupling agent NDZ-101, first dissolve the weighed isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate coupling agent with xylene solvent, and then mix with nano-SiO 2 The particles were thoroughly mixed until uniform, and put into an oven to dry to remove the solvent, wherein the drying temperature was 110° C., and the drying time was 2 hours. The addition of titanate coupling agent is nano-SiO 2 5% by weight of particles.

[0025] 2) The preparation of modified nano-montmorillonite adopts nano-montmorillonite particles with a particle size of 50nm and titanate coupling agent NDZ-101. Name?) dissolved, then fully mixed with nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com