Silver electrolysis process and equipment

A process and equipment technology, applied in the field of silver electrolysis process and equipment, can solve the problems of high labor intensity of workers, high residual risk factor, increased production cost, etc., to reduce water resources and time, reduce production costs, and improve the use of effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0067] A silver electrolysis process and equipment disclosed by the present invention comprises the following process steps:

[0068] S1: The silver slag material is melted by converter blowing to form alloy gold;

[0069] S2: crushing the alloyed gold prepared in step S1, drying and granulating to obtain granular alloyed gold;

[0070] S3: adding the granular alloy gold obtained in step S2 into an electrolytic cell without residual electrodes for silver electrolysis, and filtering and collecting the silver powder precipitated at the cathode of the electrolytic cell;

[0071] S4: washing the silver powder collected in step S3, drying after washing to make clean silver powder;

[0072] S5: casting the clean silver powder obtained in step S4 to obtain silver ingots.

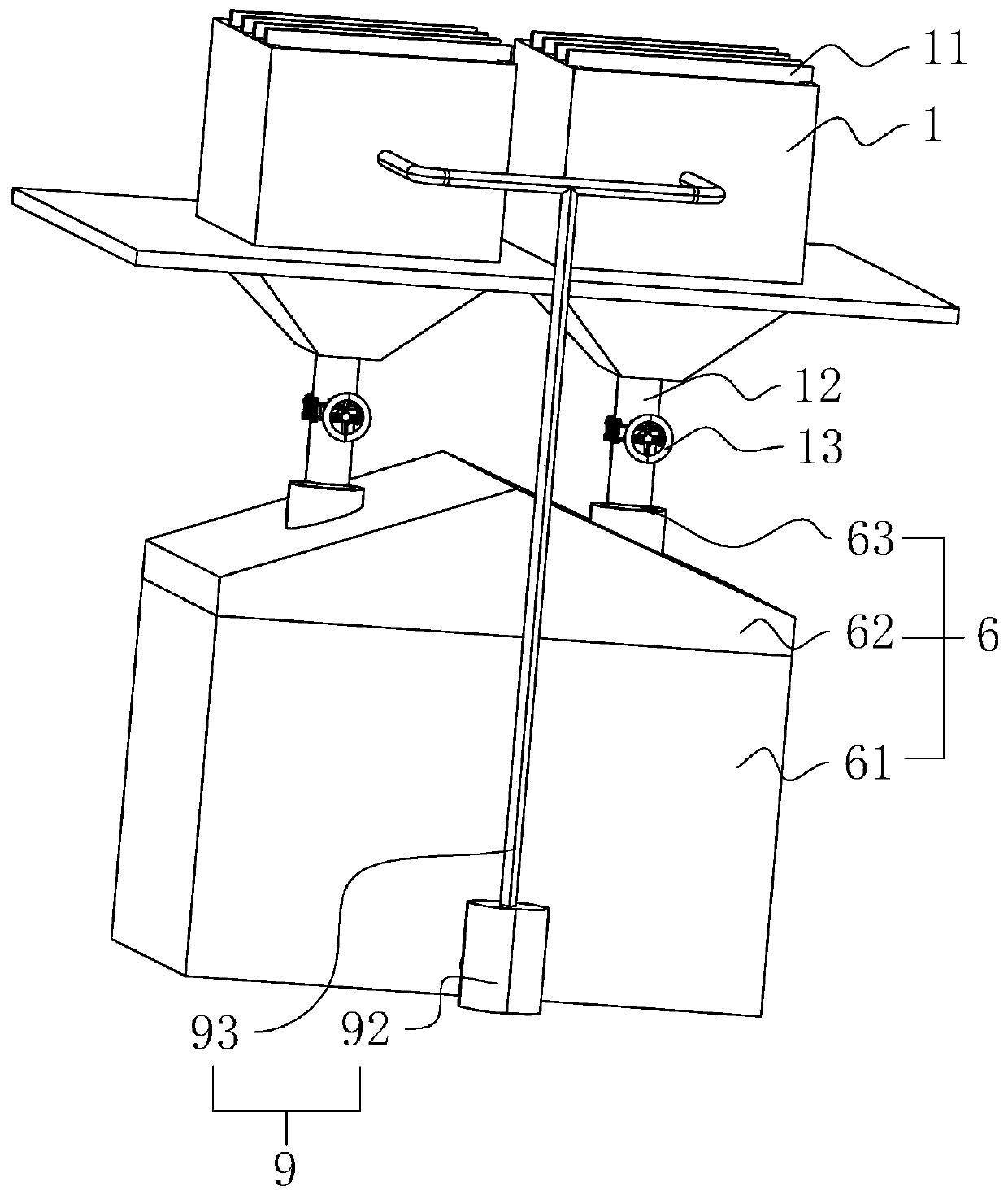

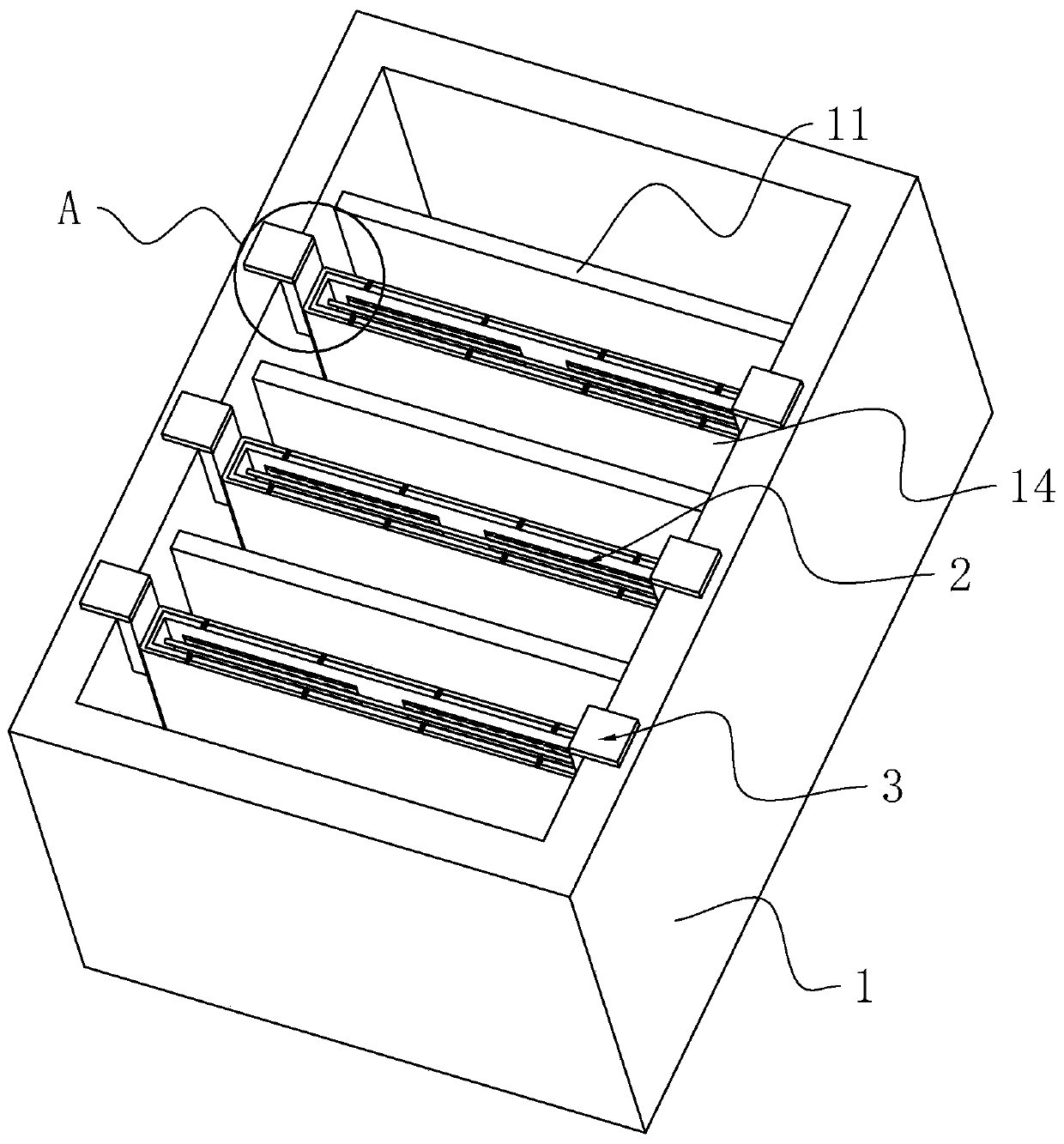

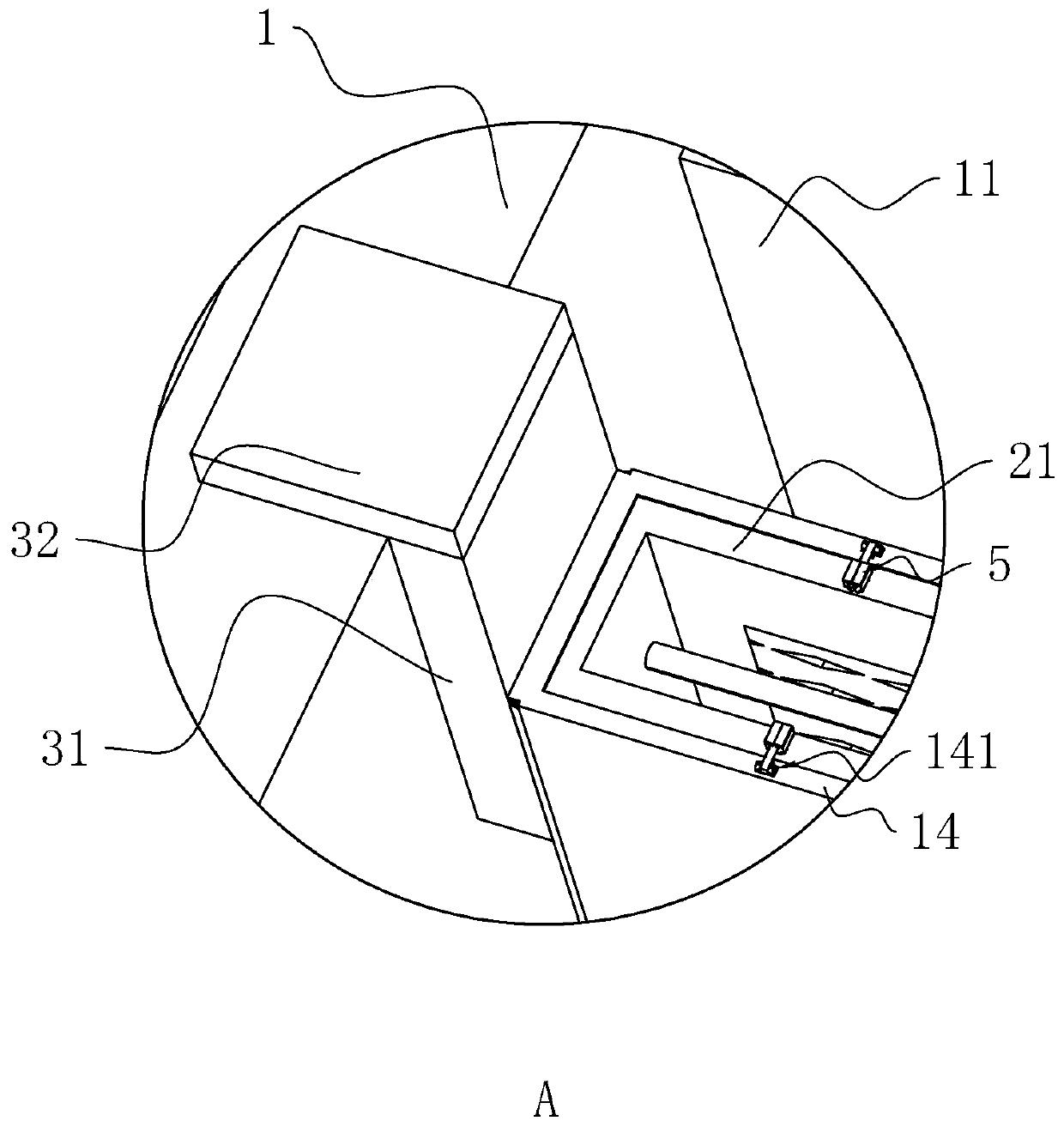

[0073] Such as figure 1 and figure 2As shown, the non-residue electrolytic cell in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com