Shale fluid-preserving sealed coring device and method

A closed coring and fluid technology, applied in the direction of extracting the undisturbed core device, earthwork drilling and mining, etc., can solve the problems of suppressed pressure blasting, unavoidable desorption of shale gas, unsuitable for shale gas, etc., to ensure calculation accuracy and improve Effects of Reliability and Economic Evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

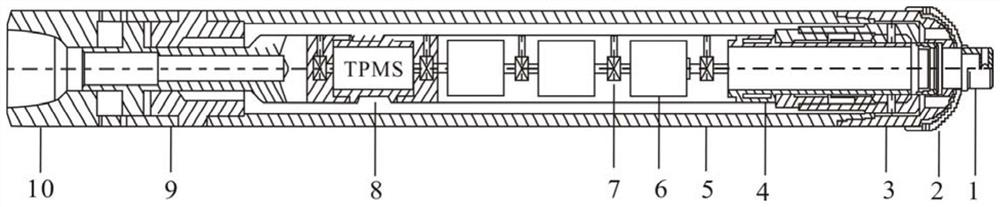

[0059] figure 1 A schematic structural view of a shale fluid-retaining sealed coring device in an embodiment of the present invention is shown.

[0060] Such as figure 1 As shown, the embodiment provides a shale fluid-preserving sealed coring device, including a coring bit 2, an outer cylinder 5 and a drill pipe joint 10 connected in sequence, and the drill pipe joint 10 can drive the outer cylinder 5 and the core bit 2 to rotate ;

[0061] In the outer cylinder 5, there are sequentially connected ball valve assembly 3, inner cylinder 4, a plurality of fluid collection tanks 6 connected in series, and a measuring device 8 while drilling; the plurality of fluid collection tanks 6 are used to collect natural gas in the core; The measuring device 8 is used to measure the temperature and pressure of the natural gas in the fluid collection tank 6;

[0062] The device also includes a suspension assembly 9, one end of the suspension assembly 9 is connected with the outer cylinder ...

Embodiment 2

[0066] This embodiment provides a shale fluid-preserving sealed coring device, and the method includes the following steps:

[0067] Step 1: Before the coring work starts, the sealing piston 1 is fixed to the piston hole of the coring bit 2 by a pin, and the inner cylinder 4 is filled with sealing liquid at the wellhead.

[0068] Step 2: Open the ball valve assembly 3, lower the shale fluid-preserving airtight coring device into the well, drill the core bit 2 at the position of the target layer, the core enters the inner cylinder 4 through the core bit 2, and the fluid collection tank 6 collects the fluid in the core. natural gas;

[0069] During the drilling process, the hydraulic mechanism relies on the circulating pressure of the drilling fluid to generate a pressure difference between the inner cylinder 4 and the outer cylinder 5, the ball valve assembly 3 is closed, and the entire outer cylinder 5 becomes an independent closed system. The temperature reduction in the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com