Polymer-based composite dielectric material, preparation method thereof and energy storage device

A technology of dielectric materials and polymers, applied in coatings and other directions, can solve the problems of increased cost, low molecular chain polarity, and inability to meet the temperature requirements of film capacitors, reducing energy loss, high energy storage density, and improving dielectric properties. The effect of electrical properties and breakdown field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

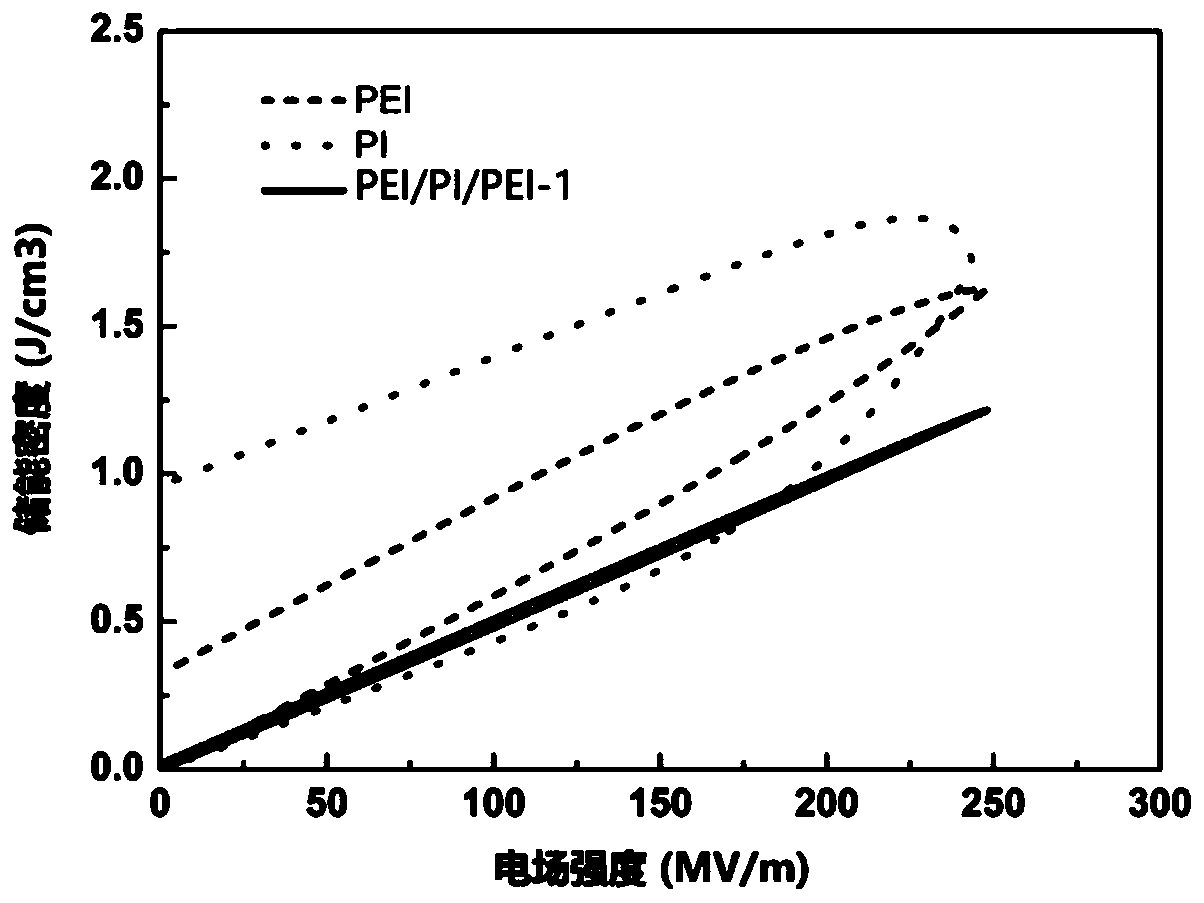

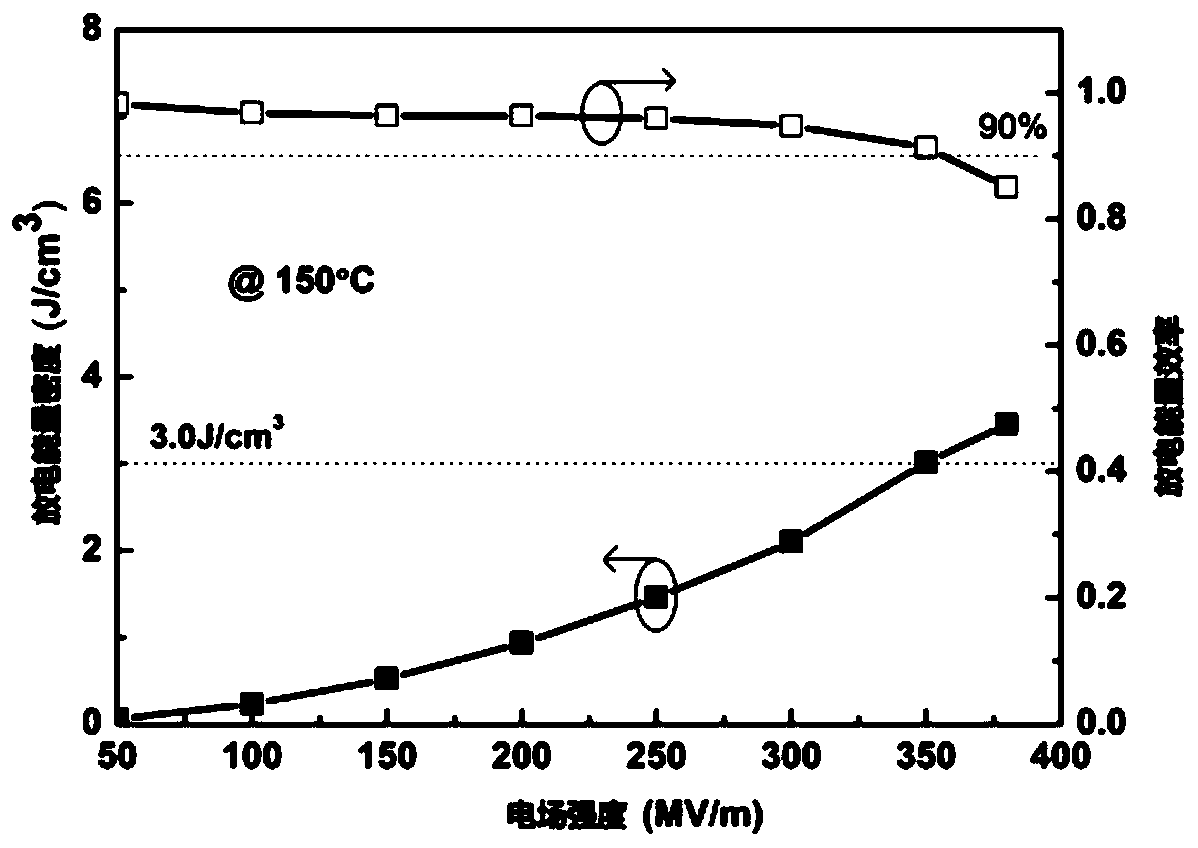

[0024] This embodiment provides a polymer-based composite dielectric material PEI / PI / PEI-1, which is prepared according to the following steps:

[0025] (1) Dissolve PEI (polyetherimide) in N, N-dimethylformamide to obtain the PEI solution required for the first polymer layer, and also as the required polymer solution for the odd-numbered layers in the multilayer structure . Soluble PI (polyimide) is dissolved in N-methylpyrrolidone to obtain the PI solution required for the second polymer layer, that is, the polymer solution required for the even-numbered layer in the multilayer structure.

[0026] (2) Cast the PEI solution on the glass substrate, and then dry it in an oven for 30 minutes to form a PEI film; then, in the same way, cast the PI solution on the surface of the PEI film to form a PI film, and cast a layer of PEI film on the surface of the PI film again , and finally place it in an oven to dry for 8 hours to obtain a composite dielectric film with a three-layer st...

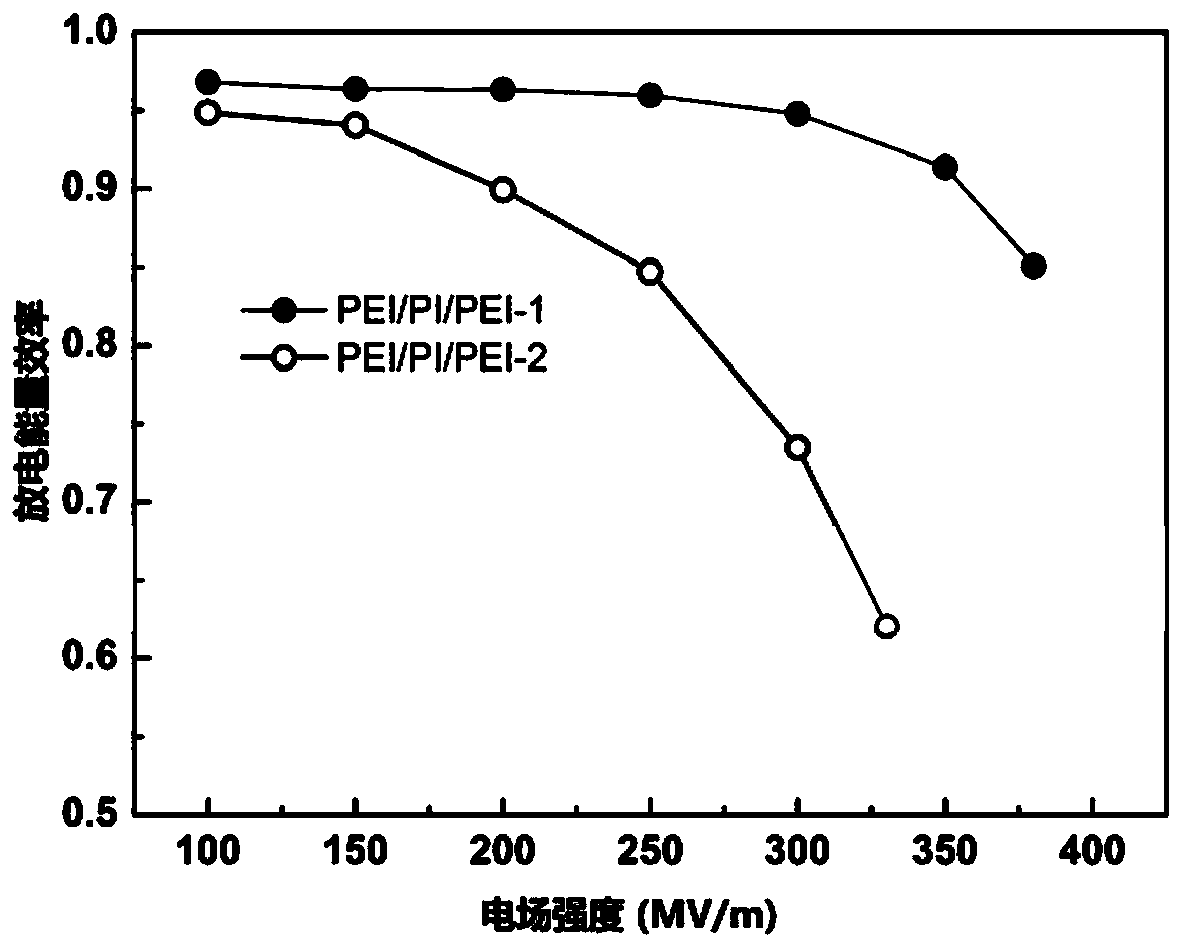

Embodiment 2

[0030] This embodiment provides a polymer-based composite dielectric material PEI / PI / PEI / PI, which is prepared according to the following steps:

[0031] (1) Dissolve PEI (polyetherimide) in N, N-dimethylformamide to obtain the PEI solution required for the first polymer layer, and also as the required polymer solution for the odd-numbered layers in the multilayer structure . Soluble PI (polyimide) is dissolved in N-methylpyrrolidone to obtain the PI solution required for the second polymer layer, that is, the polymer solution required for the even-numbered layer in the multilayer structure.

[0032] (2) Cast the PEI solution on the glass substrate, and then dry it in an oven for 30 minutes to form a PEI film; then, in the same way, cast the PI solution on the surface of the PEI film to form a PI film, and cast a layer of PEI film on the surface of the PI film again , and then cast a PI layer on the surface of the PEI film, and finally place it in an oven to dry for 8 hours t...

Embodiment 3

[0036] This embodiment provides a polymer-based composite dielectric material PEI / PI / PEI / PI / PEI, which is prepared according to the following steps:

[0037] (1) Dissolve PEI (polyetherimide) in N, N-dimethylformamide to obtain the PEI solution required for the first polymer layer, and also as the required polymer solution for the odd-numbered layers in the multilayer structure . Soluble PI (polyimide) is dissolved in N-methylpyrrolidone to obtain the PI solution required for the second polymer layer, that is, the polymer solution required for the even-numbered layer in the multilayer structure.

[0038] (2) Cast the PEI solution on the glass substrate, and then dry it in an oven for 30 minutes to form a PEI film; then, in the same way, cast the PI solution on the surface of the PEI film to form a PI film, and cast a layer of PEI film on the surface of the PI film again , and so on, alternately cast PEI and PI layers, and finally place it in an oven to dry for 8 hours to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com