Novel wear-resistant waterproof electronic material coating and preparation method thereof

A technology of coatings and nanoparticles, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as performance degradation, thin coatings, and inability to meet electronic equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] I. Preparation of Coating Compositions

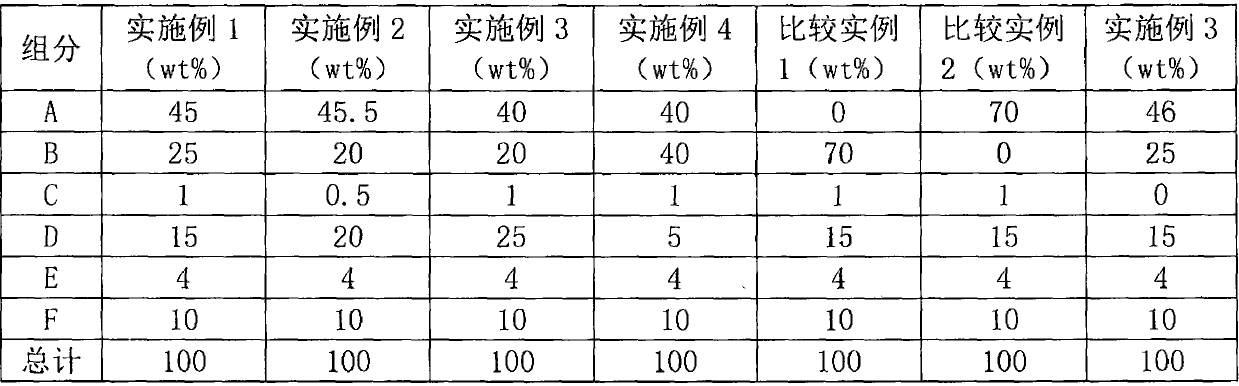

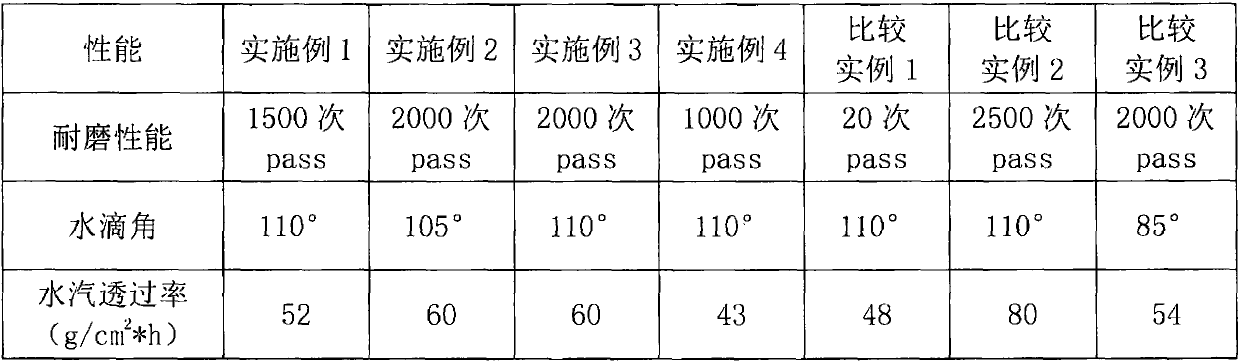

[0018] Examples 1-5 and Comparative Examples 1-3 are prepared through the components listed in Table 1 and their contents below, which illustrate the scheme in more detail, but the components of the present invention are not limited to the following examples.

[0019] Table 1. Preparation of Coating Compositions

[0020]

[0021] A. Hexafunctional urethane acrylate AgiSyn 2421, purchased from DSM

[0022] B. tetrahydrofurfuryl acrylate, purchased from Sigma-aldrich company

[0023] C.RS90, purchased from DIC Corporation

[0024] D. NANOCRYL C 150 nanometer silica, purchased from Solvay company

[0025] E.α-hydroxyalkyl phenone photoinitiator, purchased from Sigma-aldrich company

[0026] F. Butyl acetate, purchased from Sigma-aldrich company

[0027] II. Coating Preparation Process

[0028] Add the different components of A-F to the 1L flask in turn, and stir well to prepare the wet sample of the coating. It can be coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drop angle | aaaaa | aaaaa |

| Water vapor transmission rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com