Adhesive film, adhesive composition therefor, and display member comprising same

A technology for adhesive films and compositions, applied in the direction of film/sheet adhesives, non-polymer organic compound adhesives, adhesive types, etc., can solve the problems of insufficient protection of OLED panels, etc., and achieve good Effects of non-brittle properties, high peel strength, good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

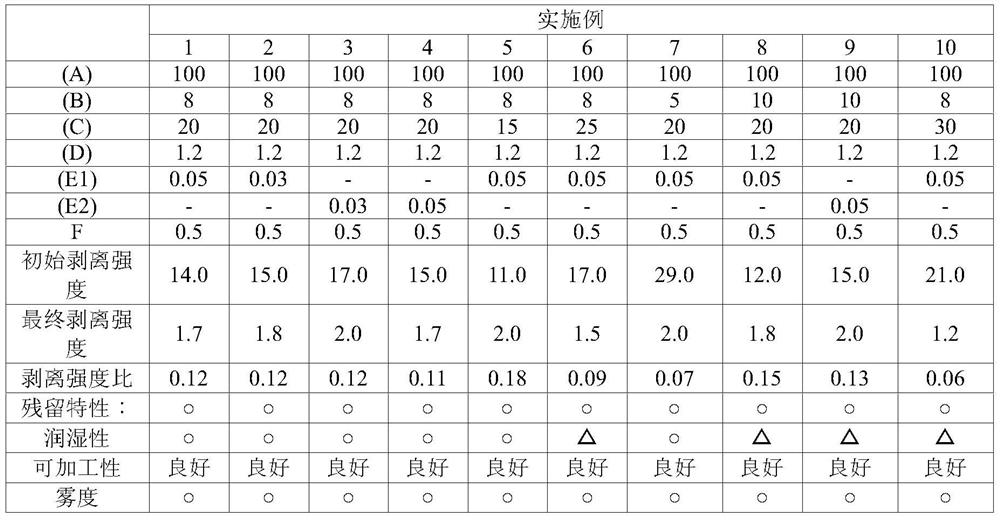

[0108] With 100 parts by weight of polyurethane resin prepared in Preparation Example, 8 parts by weight of isocyanate curing agent, 20 parts by weight of multifunctional (meth)acrylate monomer, 1.2 parts by weight of photoinitiator, 0.5 parts by weight of The thermal initiator and 0.05 parts by weight of the bipolar additive (E1) were mixed with 5.0 parts by weight of toluene, followed by stirring for 30 minutes, thereby preparing an adhesive composition.

[0109] The prepared adhesive composition was coated on a polyethylene terephthalate (PET) film (SKC, thickness: 75 μm) as a base film, and then dried at 130° C. A 75 μm thick adhesive layer was formed. Then, a 25 μm thick release film (silicone release layer) was attached to the adhesive layer, followed by aging at room temperature for 1 week, thereby obtaining a 75 μm thick adhesive layer and a 25 μm thick release film in this order. Film stack formed on PET film.

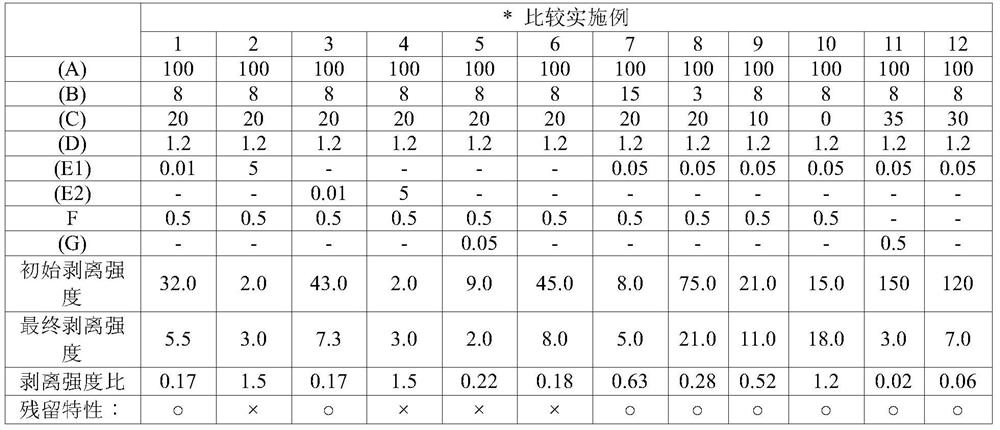

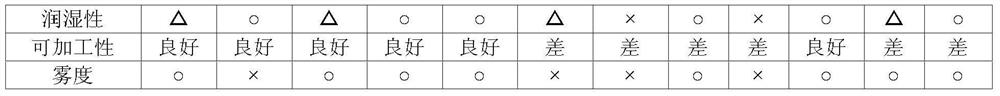

Embodiment 2 to 10

[0111] A film laminate was obtained in the same manner as in Example 1, except that the amounts of the respective components of the adhesive composition were changed as listed in Table 1 (unit: parts by weight).

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com