Thoracic aorta covered stent with degradable bare area

A thoracic aorta and stent-graft technology, applied in the field of medical devices, can solve problems such as blood vessel rupture and affect long-term effects, achieve the effect of supporting and bending, reduce the use of raw materials, and avoid scratches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

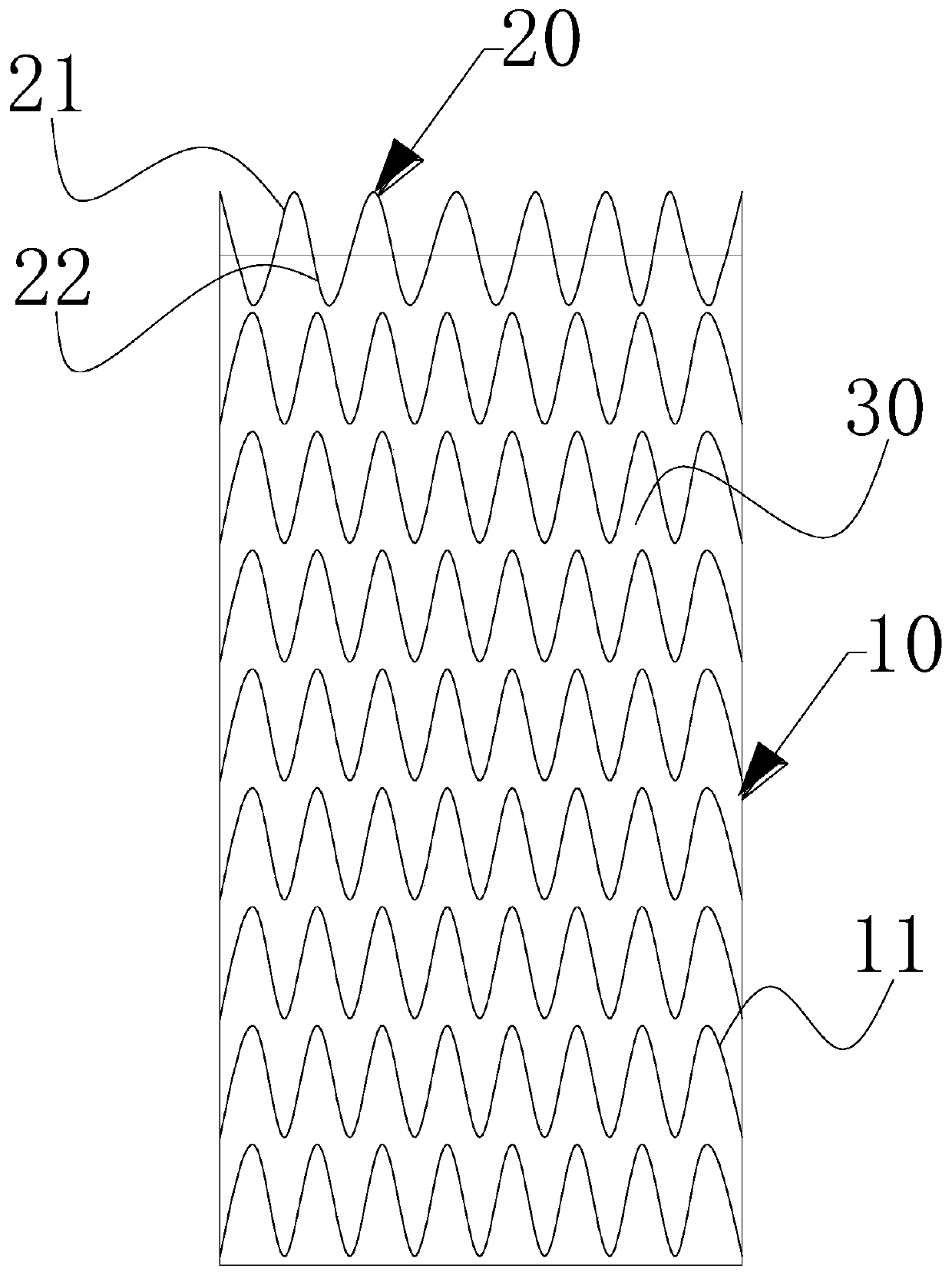

[0024] like figure 1 As shown, a bare area degradable thoracic aortic stent graft includes a fixed stent 20 and several wavy thoracic aortic stent units 11, each thoracic aortic stent unit 11 is coiled into a ring, and several coiled The annular thoracic aortic stent units 11 are arranged sequentially to form a tubular thoracic aortic stent 10; the fixed stent 20 is wave-shaped, and the fixed stent 20 is wound into a ring, and several thoracic aortic stents 10 are coated with a polyester film 30, The thoracic aortic stent 10 and the polyester film 30 are tubular as a whole, and the fixed stent 20 is divided into upper and lower parts along its radial direction, which are respectively a bare section 21 and a connecting part 22, and the connecting part 22 is arranged at one end of the polyester film 30 , the bare section 21 protrudes from one end of the polyester film 30, and the connecting part 22 is also coated with the polyester film 30; the bare section 21 of the fixing brac...

Embodiment 2

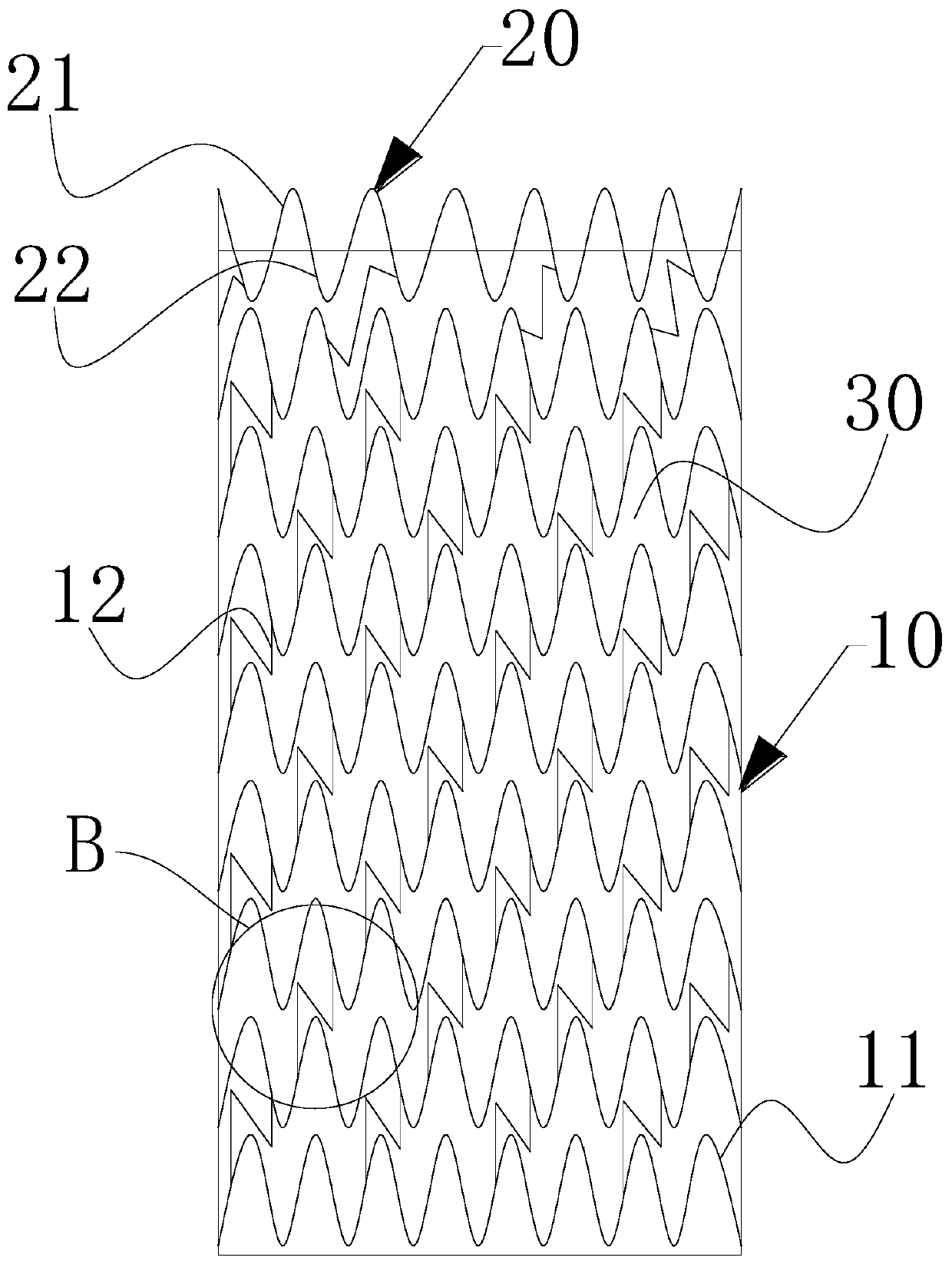

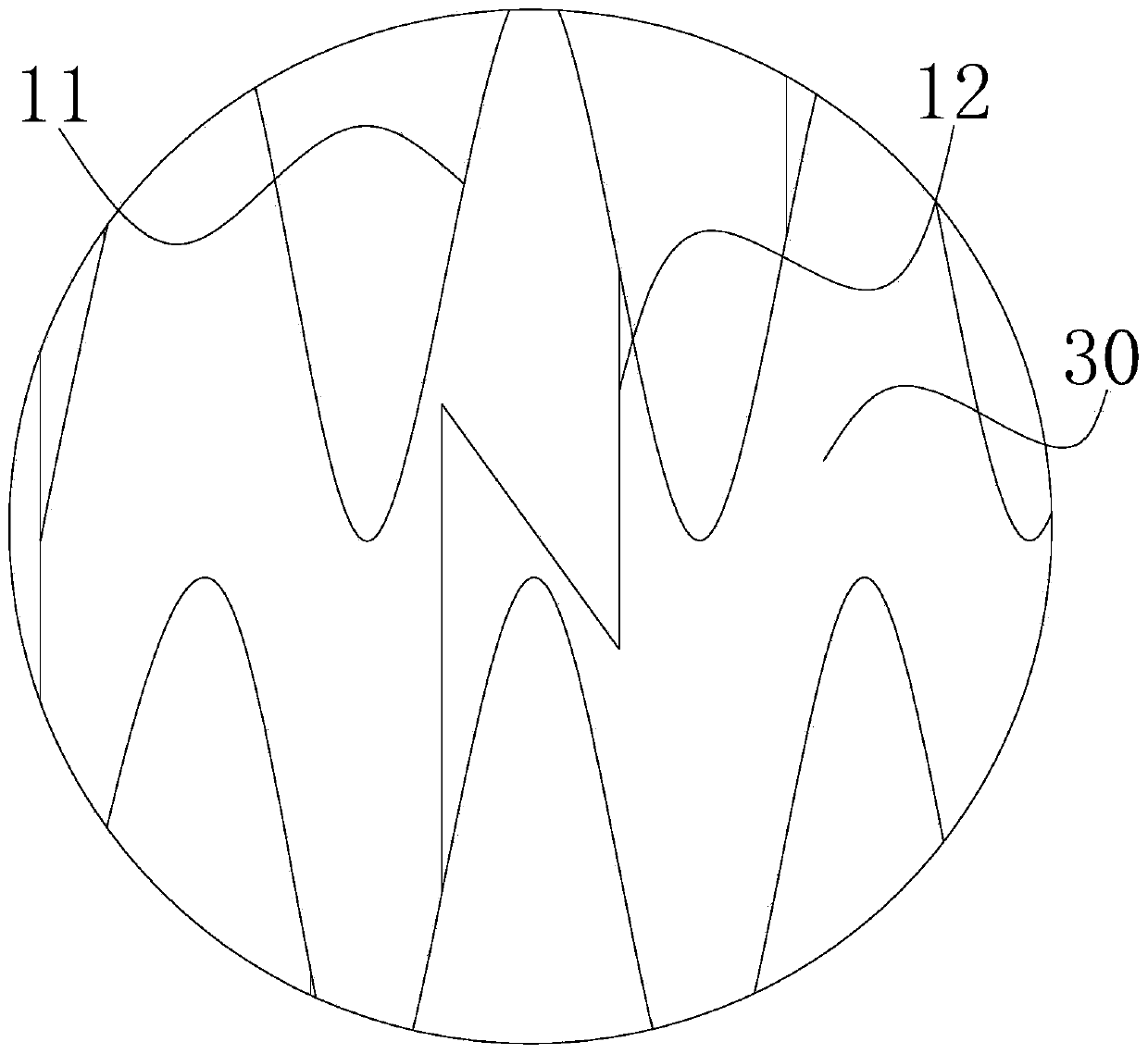

[0028] like figure 2 and image 3 As shown, this embodiment is based on Embodiment 1. Several Z-shaped frames 12 are arranged between adjacent thoracic aortic stent units 11, and the two ends of the Z-shaped frames 12 are respectively connected to adjacent thoracic aortas. Nodes of the wave-shaped structure of the bracket unit 11 . There is an interval of 1.5 cycles between two adjacent Z-shaped frames 12 in the circumferential direction of the polyester film 30 , and the adjacent Z-shaped frames 12 in the axial direction of the polyester film 30 are alternately arranged.

[0029] By setting the Z-shaped frame 12, several thoracic aortic stent units 11 can be connected into a whole, and the structure of the Z-shaped frame 12 also has a certain degree of expansion and contraction ability, and can perform certain automatic adjustments along with the expansion and contraction of the thoracic aorta stent 10. Adjustment, support effect and bending effect are better.

[0030] Th...

Embodiment 3

[0034] This embodiment is improved on the basis of Embodiment 1. The fixing bracket 20 is made of iron alloy wire. Since the material in the bare area will degrade in the artery, the stimulating effect of the bare area on the arterial wall will gradually disappear.

[0035] The rest of the structure and working principle of embodiment 3 are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com