A slicing method, method, product and equipment for 3D printing

A 3D printing and slicing technology, applied in the field of additive manufacturing, can solve problems such as dead corners and too small partitions, and achieve the effect of improving surface flatness, partitioning uniformity, and reducing component cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

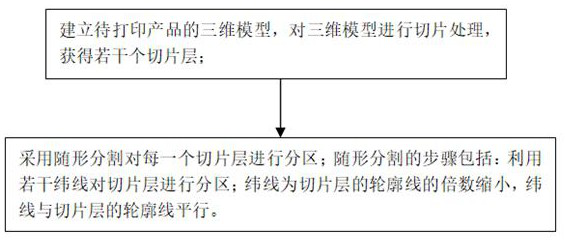

[0074] A slicing method for 3D printing, comprising the following steps:

[0075] S1. Establish a three-dimensional model of the product to be printed, and slice the three-dimensional model to obtain several slice layers; the slice layers are as follows: image 3 shown.

[0076] S2. Using conformal segmentation to partition each slice layer; the step of conformal segmentation includes:

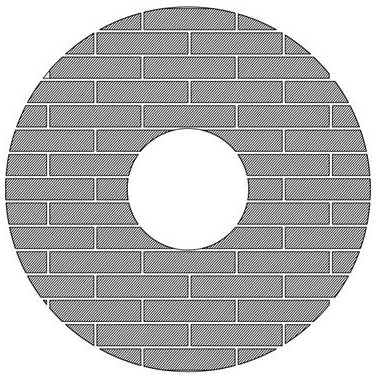

[0077] S201. Use several weft lines 1 to partition the slice layer; the weft line 1 is reduced by a multiple of the contour line of the slice layer, and the weft line 1 is parallel to the contour line of the slice layer. The spacing between any two adjacent wefts 1 is equal, and the spacing between adjacent wefts 1 is 25 mm, such as Figure 4 shown.

[0078] S202. After partitioning the slice layer by using several weft threads 1, partition the slice layer again by using several warp threads 2, where the warp thread 2 is the normal line of the latitude thread 1, and the warp thread 2 inters...

Embodiment 2

[0084] The 3D printing slicing method of this embodiment is basically the same as that of Embodiment 1, except that the distance between adjacent latitude lines 1 is 40 mm, and the length of sub-line segments is 200 mm. Then use weft 1 to partition, that is, step S202 is executed first, and then step S201 is executed.

[0085] Observation of the metal components of this embodiment shows that the surface is smooth and free of cracks.

Embodiment 3

[0087] The 3D printing slicing method of this embodiment is basically the same as that of Embodiment 1, except that the distance between adjacent parallel lines 1 is 32 mm, and the length of sub-lines is 170 mm.

[0088] Observation of the metal components of this embodiment shows that the surface is smooth and free of cracks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com