Intelligent production line for intelligent ceramic tile heating module

A heating module and production line technology, applied in ceramic forming machines, ceramic forming workshops, auxiliary forming equipment, etc., can solve the problems of difficult production quality assurance, high labor intensity of workers, low production efficiency, etc. The effect of low labor intensity and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

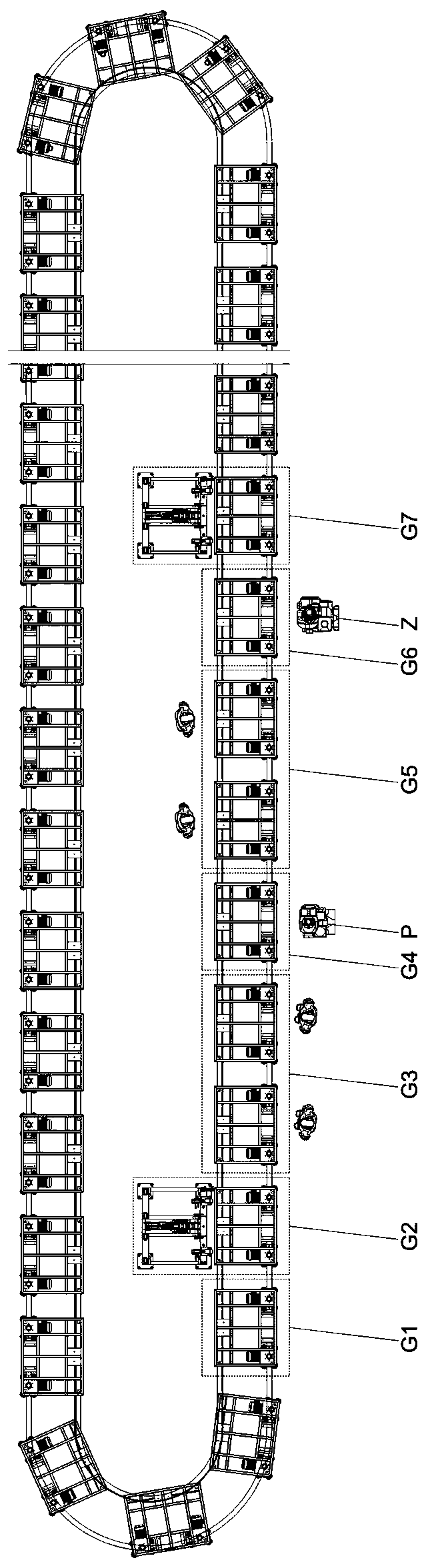

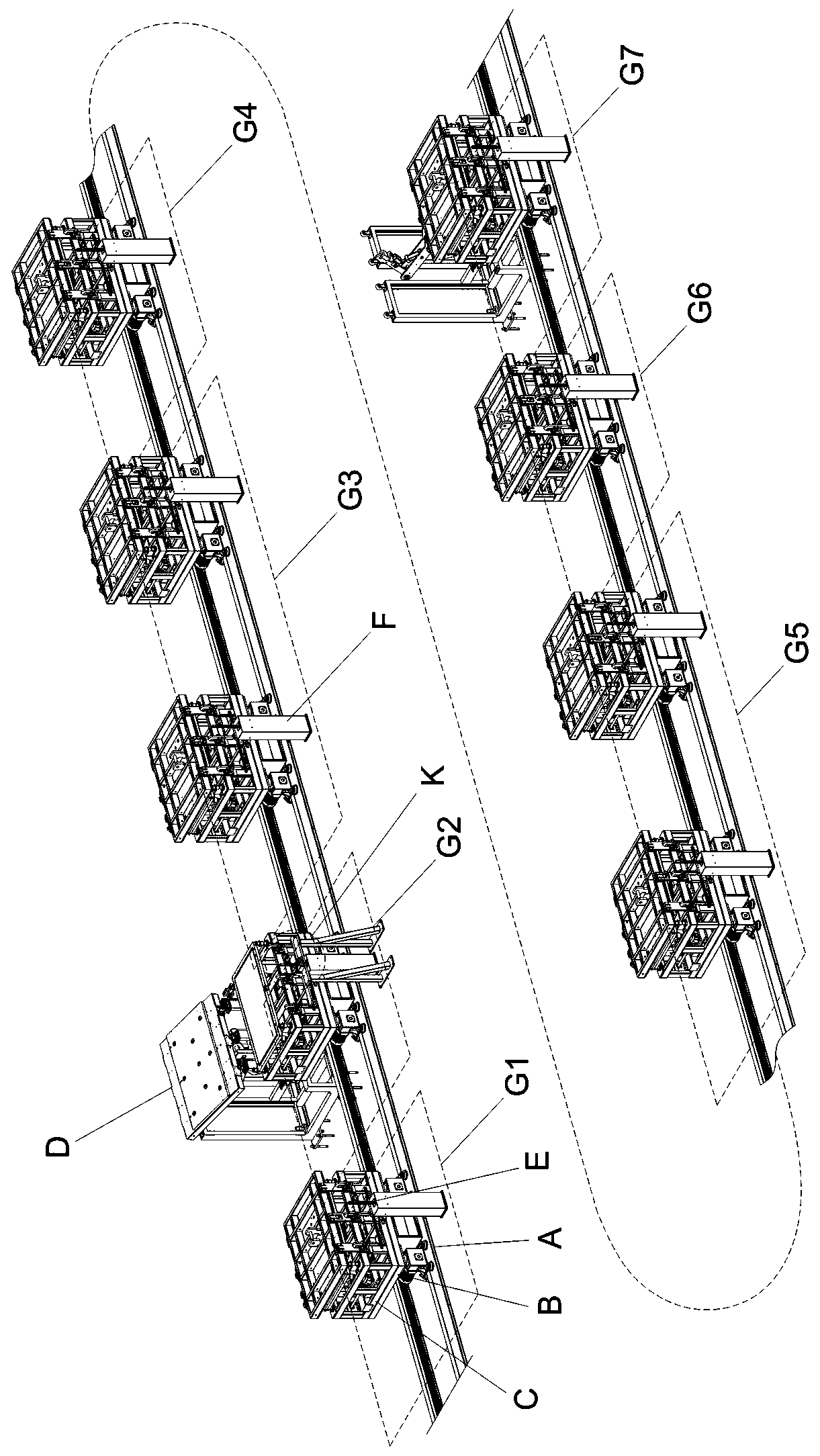

[0041] see Figure 1-Figure 18 , the intelligent production line of heating modules for smart heating tiles is used to produce heating modules in smart heating tiles. Specifically, the heating film T and foam board are combined to produce heating modules in smart heating tiles.

[0042] The intelligent production line of intelligent heating tile heating module includes

[0043] Circular track A, circular track A is set in a runway-shaped ring;

[0044] RGV transport vehicle B, more than one RGV transport vehicle B slides along the circular track A, and is automatically started and stopped by PLC control;

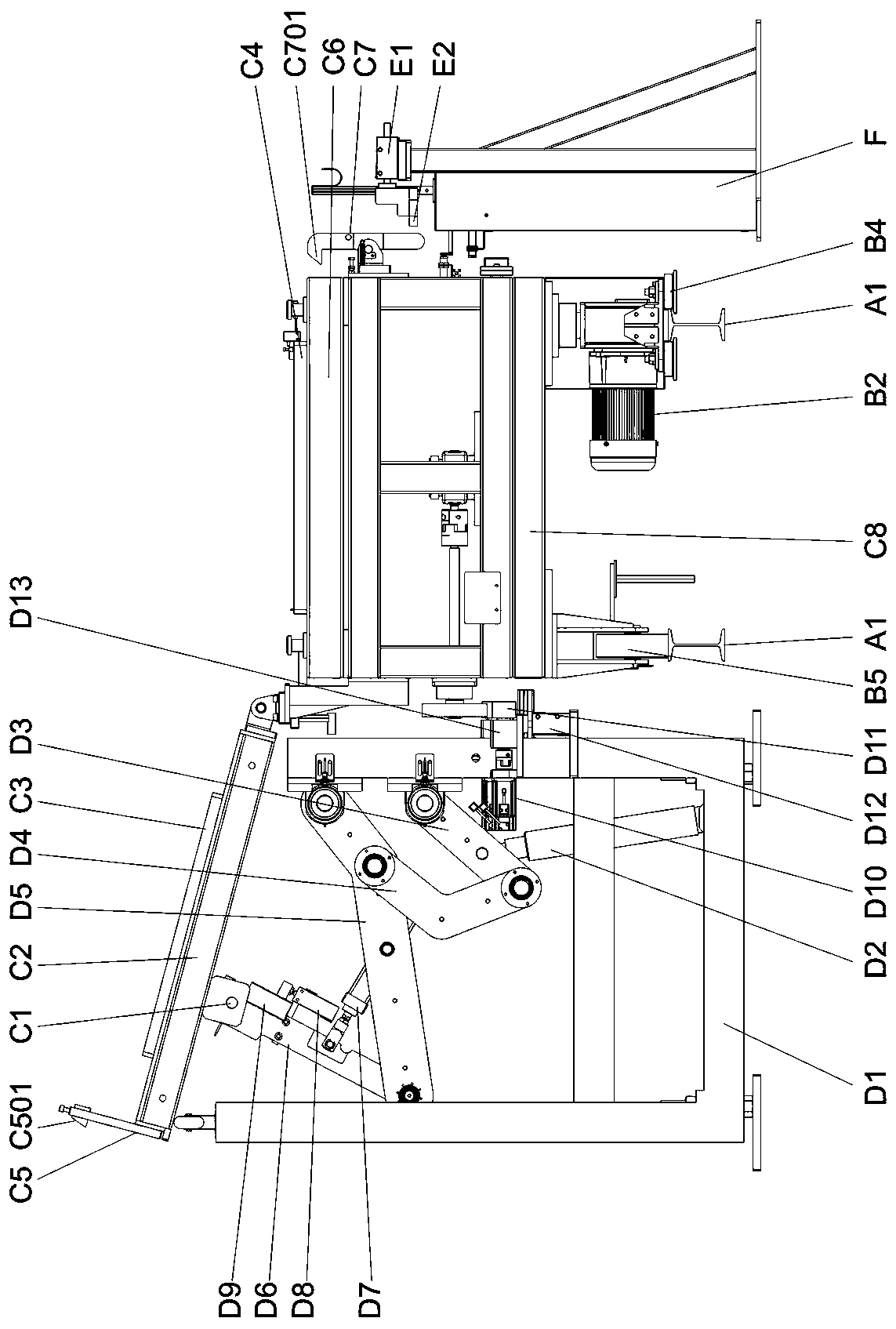

[0045]Foaming device C, foaming device C is installed on the RGV transport vehicle B, and slides along the circular track A through the RGV transport vehicle B to transport the foaming device C to different stations in sequence; the foaming device C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com