Automatic cigarette case production device

A technology for producing a device and a cigarette case, which is applied in the field of tobacco, can solve the problems of poor adhesion and assembly, low efficiency and yield, a large number of manpower, etc., and achieves the effects of high yield and improved packaging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further elaborated and illustrated:

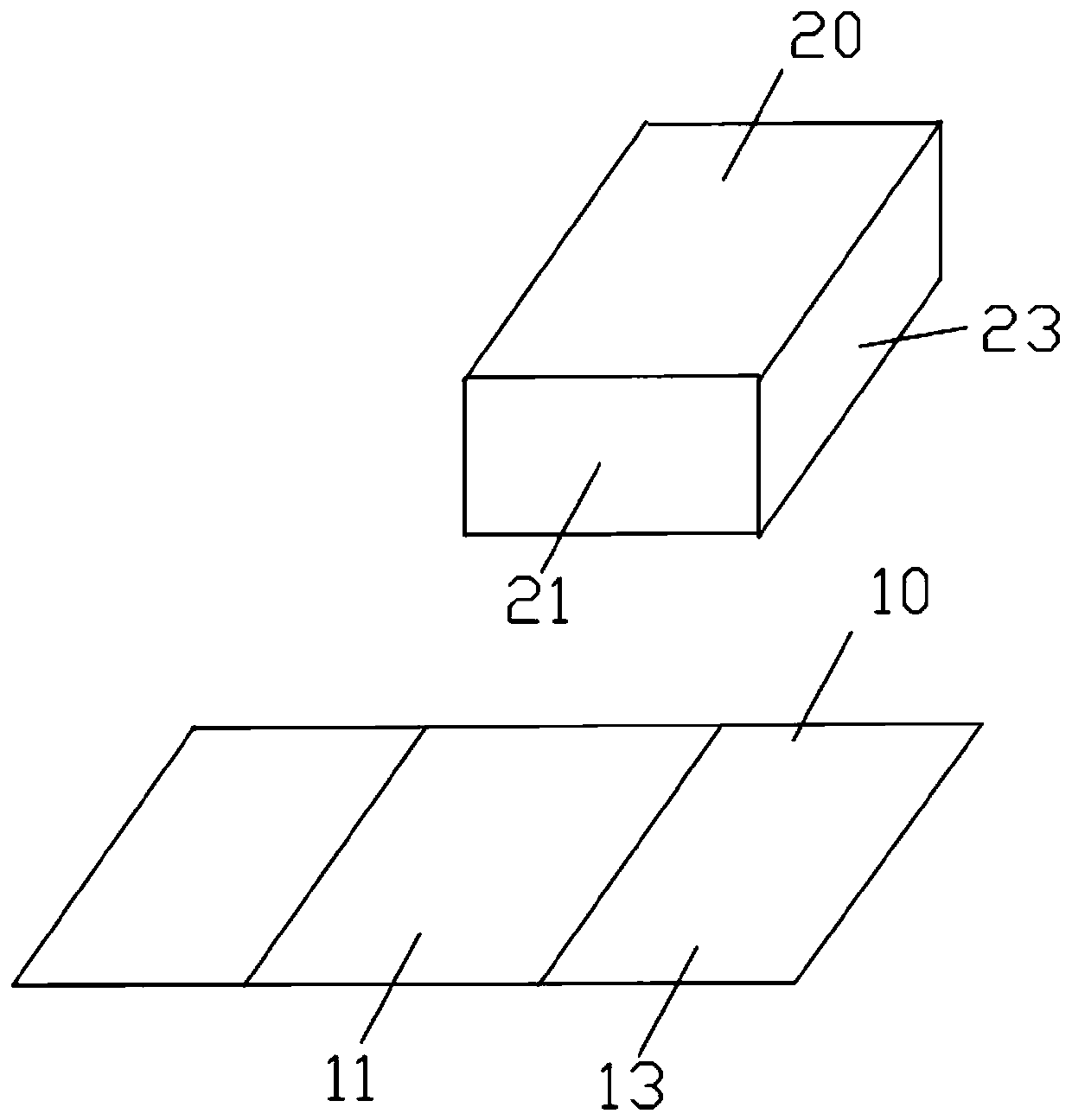

[0030] Please refer to figure 1 , figure 1 Among them, the cigarette case that needs to be assembled in this technical solution includes a leather case 10 and an inner case 20 . In this embodiment, a V-groove has been made on the surface of the leather case 10 , and the leather case 10 is divided into a central region 11 and a side region 13 . Wherein, the bottom 21 of the inner box 20 is pasted on the middle area 11 of the leather case 10 . The side walls 23 of the inner box 20 are bonded to the side regions 13 of the leather case 10 . Here, the leather case is mainly for non-metallic materials, and the outer packaging of cigarette boxes is mostly made of cardboard. Because the hardness of the processed material is not high, the processing process is also relatively difficult.

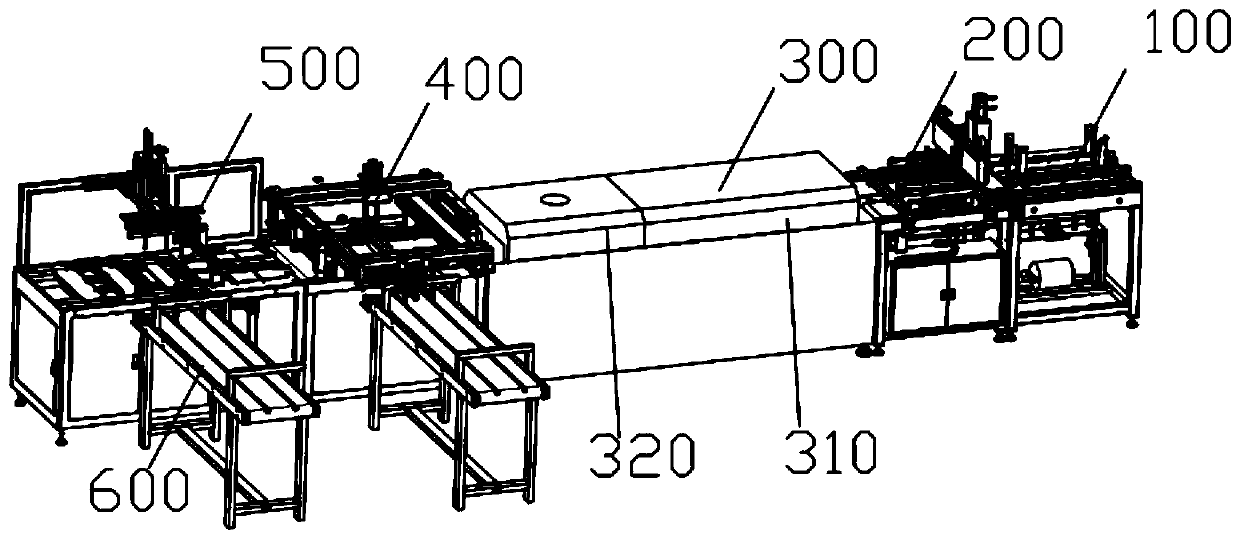

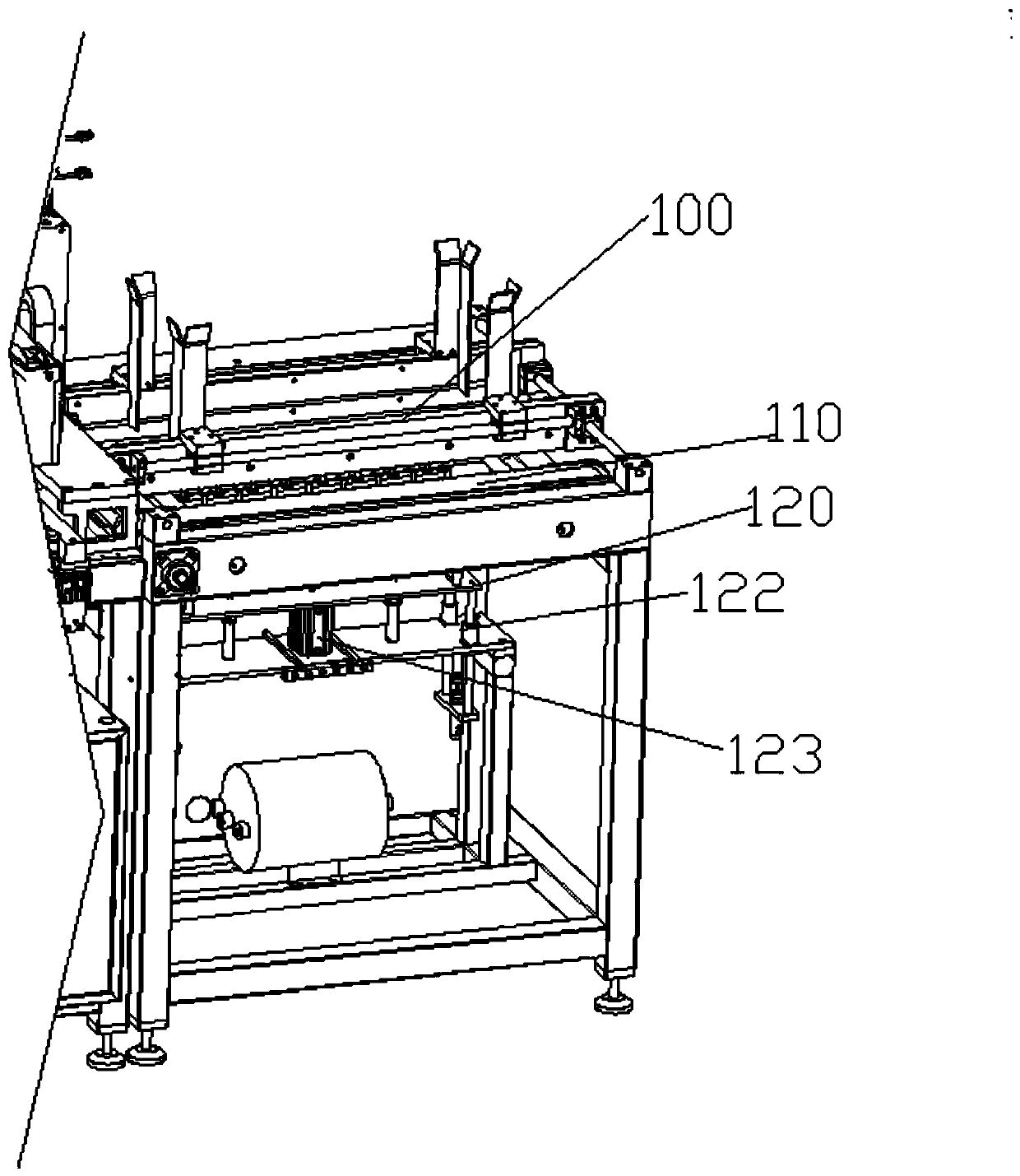

[0031] see figure 2 , The automatic production devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com