A local gluing machine for color boxes

A gluing machine and partial technology, applied in the field of gluing, can solve the problems of low paper feeding accuracy, single structure, difficult to replace, etc., and achieve the effects of reducing floating dust and cardboard tilt, scientific and reasonable structure, and safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

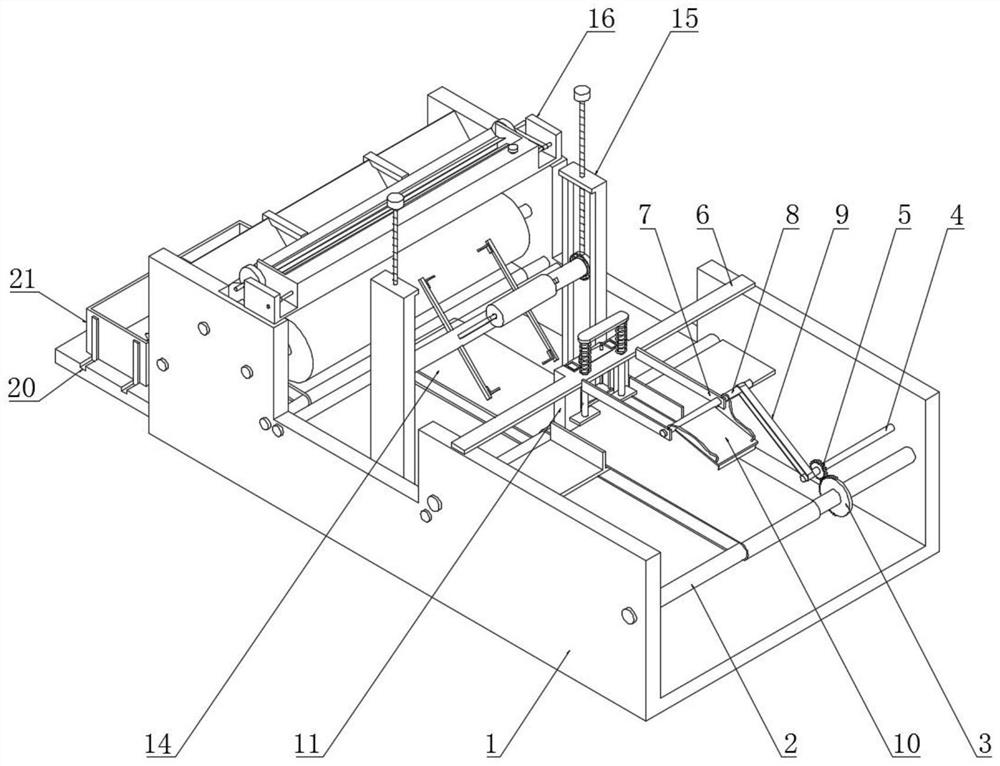

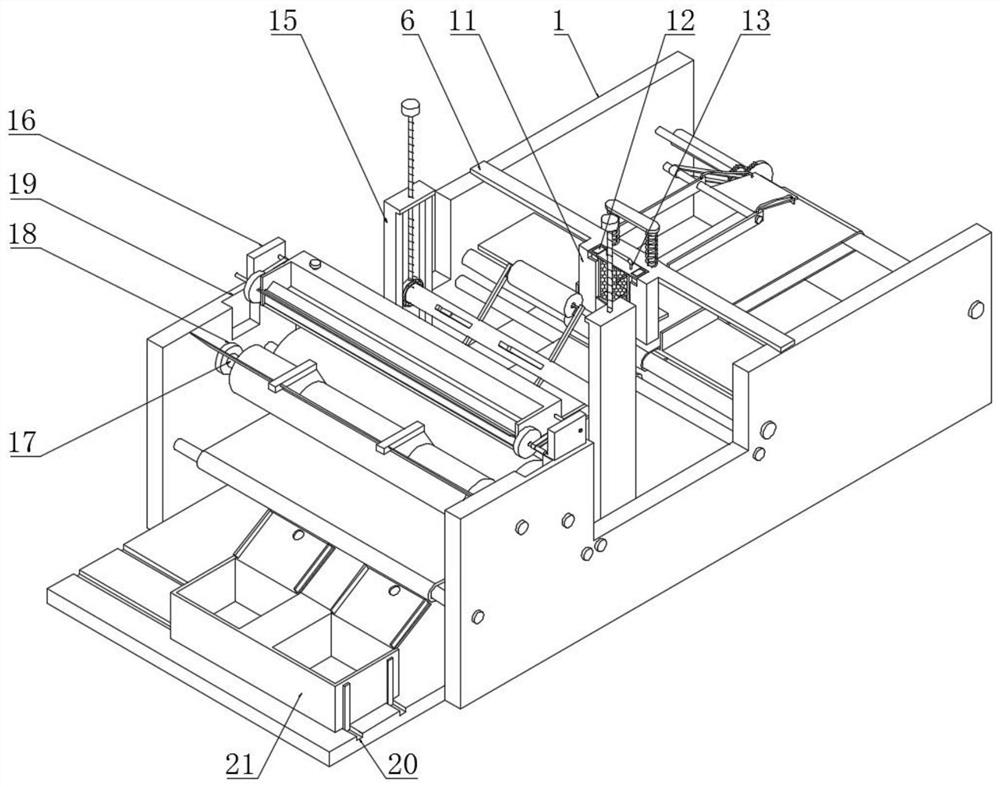

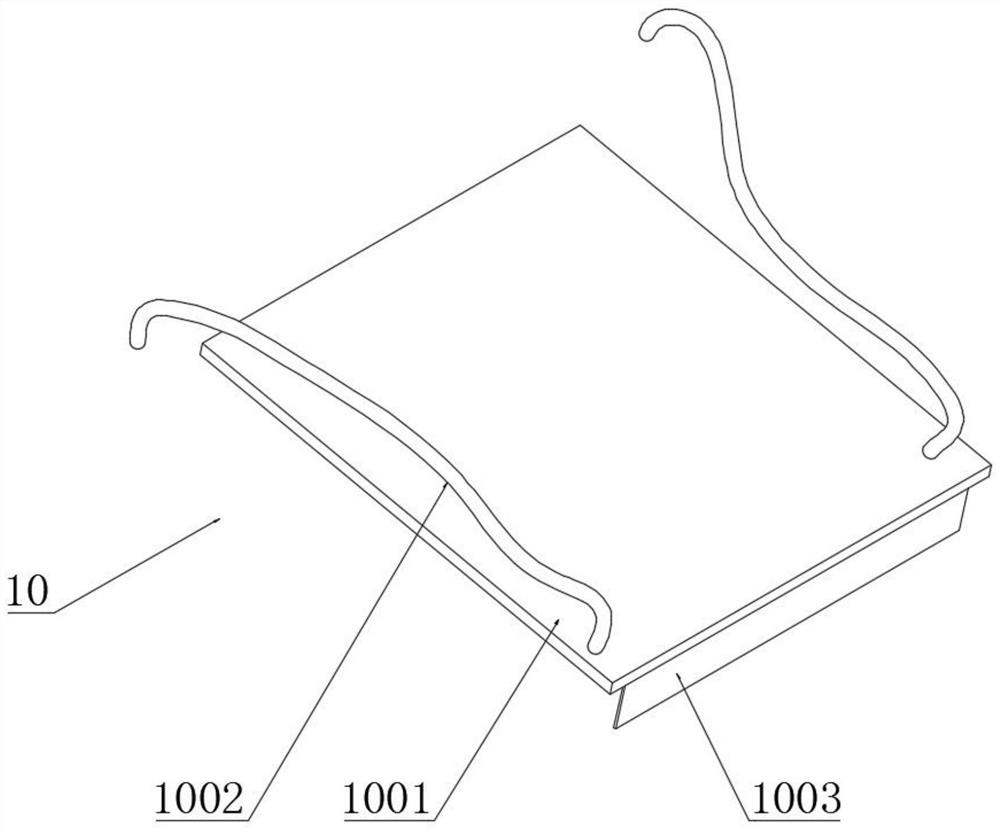

[0032] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a local gluing machine for color boxes, including a fuselage 1, a paper feed installation roller 2 is installed on one side of the fuselage 1, and an adjustment gear 3 is installed on one side of the paper feed installation roller 2 , an auxiliary roller 4 is installed at the position above the paper feeding installation roller 2 on one side of the fuselage 1, a driven gear 5 is installed at the position corresponding to the adjustment gear 3 in the middle of the auxiliary roller 4, and a mounting rod 6 is installed on the top of the fuselage 1, and the mounting rod 6 A mounting plate 7 is installed symmetrically on one side, and a swing shaft 8 is installed on one side of the mounting plate 7. One end of the swing shaft 8 is installed and connected with the auxiliary roller 4 through a transmission belt 9. A paper pushing assembly 10 is installed on one side of the swing shaft 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com