Encapsulation film

A technology of encapsulation film and encapsulation layer, which can be applied to household seals, synthetic resin layered products, and other household appliances, and can solve problems such as OLED bright spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

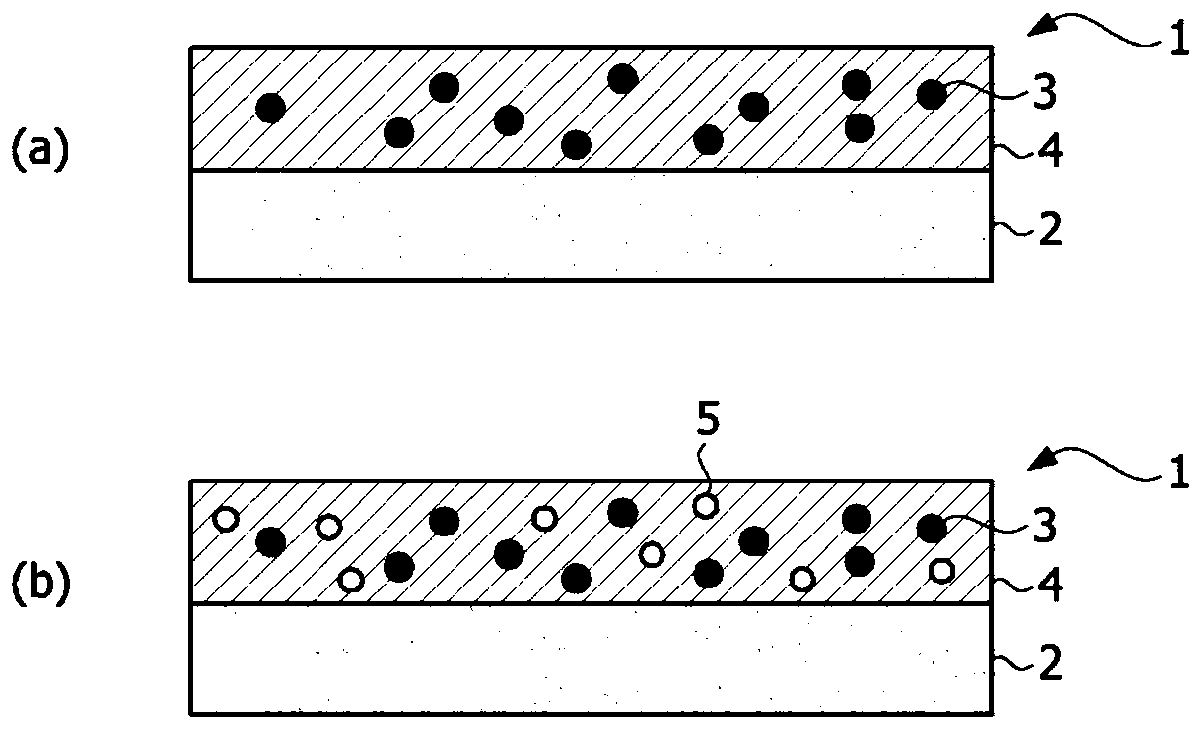

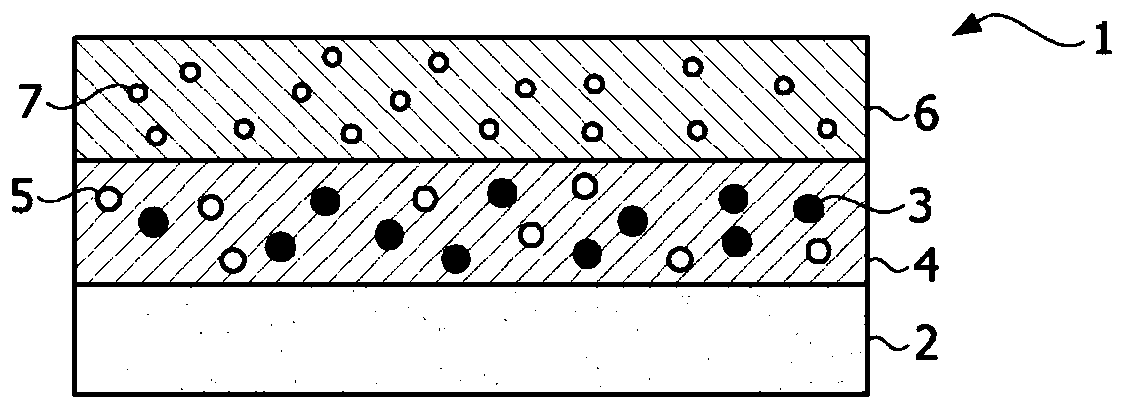

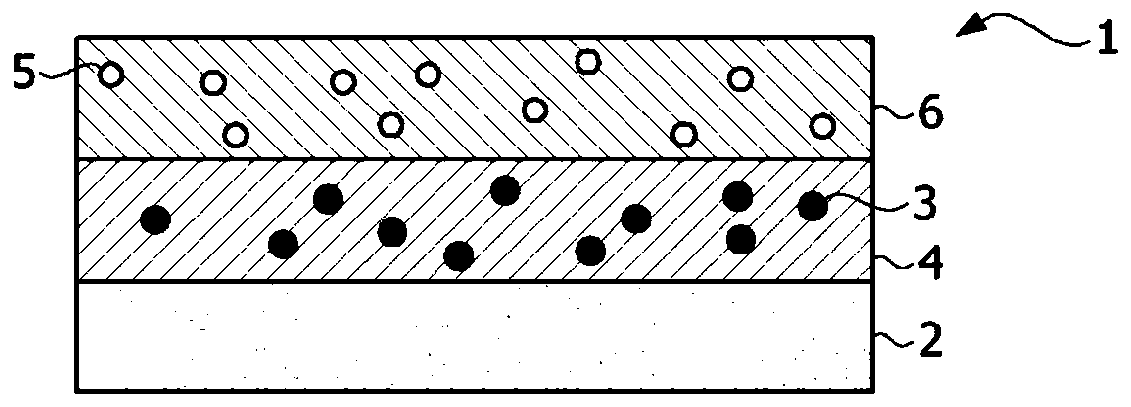

[0094] Manufacture of encapsulation layer

[0095] To prepare the first layer solution, a solution in which 180 g of butyl rubber resin (BT-20, Sunwoo Chemtech) and 60 g of DCPD (dicyclopentadiene) petroleum resin (SU5270, Sunwoo Chemtech) were diluted with toluene was prepared (solid content was 33%), and then the solution was homogenized. Introduce 10 g of multifunctional acrylate (trimethylolpropane triacrylate, Miwon) and 3 g of photoinitiator (Irgacure 819, Ciba) into the homogenized solution, make it homogenized and then stir at high speed for 1 hour, to prepare the first layer solution.

[0096] To prepare the second layer solution, a calcined dolomite (average particle diameter 3 μm) solution (solid content 50%) was prepared as a hygroscopic agent. In addition, 140 g of polyisobutylene resin (weight-average molecular weight: 450,000), 14 g of Ni particles (particle diameter: about 300 nm) as a bright spot suppressor, and 60 g of hydrogenated dicyclopentadiene resin a...

Embodiment 2 to 9 and comparative example 1 to 5

[0102] An encapsulation film was manufactured in the same manner as in Example 1 except that the bright spot suppressor was changed as shown in Table 1.

[0103] [Table 1]

[0104]

experiment example 1

[0105] Experimental Example 1 - Calculation of Adsorption Energy

[0106] The adsorption energies of the bright spot suppressors used in Examples and Comparative Examples to exhaust gas were calculated by electronic structure calculation based on density functional theory. After making a two-dimensional flat plate structure exposed on the surface where the closest-packed filling surface of the bright spot suppressor having a crystalline structure is made, structural optimization is performed, and a structure in which bright spot-causing molecules are adsorbed on the surface in a vacuum state is carried out. After structure optimization, a value obtained by subtracting the total energy of molecules causing bright spots from the total energy difference of these two systems was defined as the adsorption energy. For the calculation of the total energy for each system, the modified PBE function as a function of the GGA (Generalized Gradient Approximation) series is used as the exch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com