Soda residue soil regeneration backfill material and preparation method thereof

A technology for alkaline slag and alkaline slag, which is applied in the field of alkaline slag soil regeneration backfill material and its preparation, can solve the problems of polluted water body and soil, loss of decomposing ability of soil, damage to soil structure, etc. The effect of increasing land use resources and environmental benefits is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Correspondingly, the embodiment of the present application also provides a preparation method of the above-mentioned recycled alkali slag backfill material, and the above-mentioned preparation method includes the following steps:

[0031] Pretreatment of the dregs: stirring the above dregs to make the texture uniform, and removing foreign matter in the above dregs;

[0032] Each component is weighed according to the formula of the above-mentioned alkaline slag soil regeneration backfill material;

[0033] mixing and stirring water and the above-mentioned components to obtain a mixture, wherein the weight of the above-mentioned water accounts for 45%-55% of the total weight of the above-mentioned mixture;

[0034] The above mixture is dehydrated and solidified in the natural environment for 1-3 days to obtain the finished product.

[0035] Optionally, during the preparation process of the above-mentioned alkali dregs soil regenerated backfill material, when the weight o...

Embodiment 1

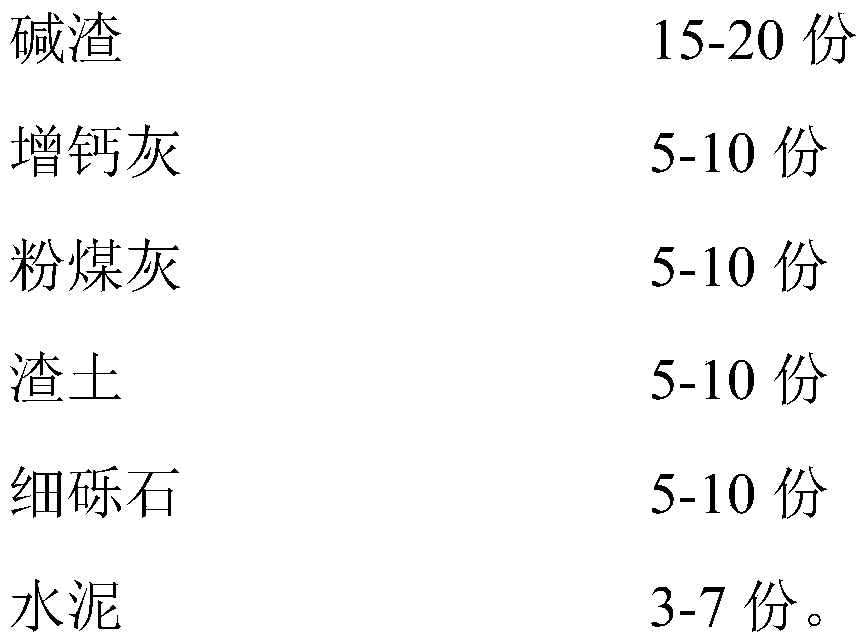

[0043] Alkali slag soil recycled backfill material and preparation method thereof. Wherein, the formula of the above-mentioned alkaline slag soil regeneration backfill material is as follows:

[0044]

[0045] Wherein, the content of fine-grained clay or silt with a particle size of 3mm in the above-mentioned muck is 30%, and the diameter of the above-mentioned fine gravel is 18mm.

[0046] The preparation method of the above-mentioned alkaline slag soil recycled backfill material comprises the following steps:

[0047] 1) Pre-treating the dregs: stirring the above dregs to make them uniform in texture, and removing foreign matter in the dregs;

[0048] 2) each component is weighed respectively according to the formula of above-mentioned alkali dregs soil regeneration backfill material,

[0049] 3) mixing and stirring water and the above-mentioned components to obtain a mixture, wherein the weight of the above-mentioned water accounts for 50% of the total weight of the ab...

Embodiment 2

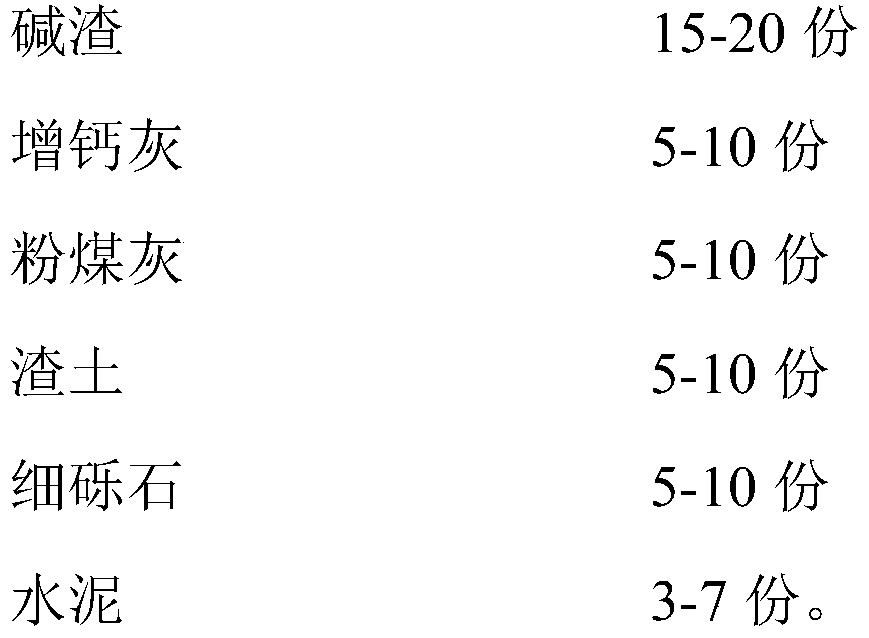

[0053] Alkali slag soil recycled backfill material and preparation method thereof. Wherein, the formula of the above-mentioned alkaline slag soil regeneration backfill material is as follows:

[0054]

[0055] Wherein, the content of fine-grained clay or silt with a particle size of 3mm in the above-mentioned muck is 60%, and the diameter of the above-mentioned fine gravel is 20mm.

[0056] The preparation method of the above-mentioned alkaline slag soil recycled backfill material comprises the following steps:

[0057] 1) Pre-treating the dregs: stirring the above dregs to make them uniform in texture, and removing foreign matter in the dregs;

[0058] 2) each component is weighed respectively according to the formula of above-mentioned alkali dregs soil regeneration backfill material,

[0059] 3) mixing and stirring water and the above-mentioned components to obtain a mixture, wherein the weight of the above-mentioned water accounts for 45% of the total weight of the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com