A matching thin film for a frequency doubling element of an intense laser device and its preparation method

A strong laser and frequency doubling technology, applied in the field of optical materials, can solve the problems of difficult control of the reaction process and environmental pollution, and achieve the effects of low mechanical strength, short service life and excellent film performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

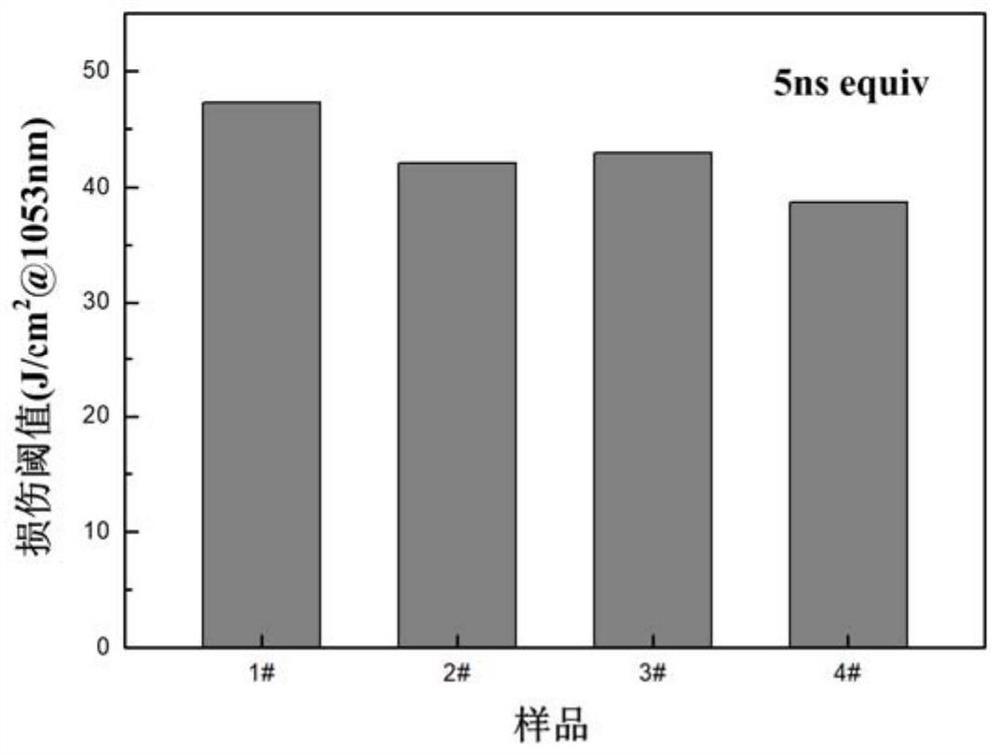

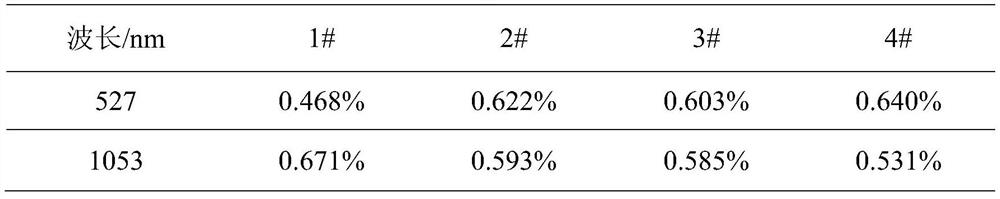

[0027] The preparation method of the frequency doubling element matching film of the intense laser device in this embodiment includes the following steps:

[0028] (1) Add 30 mol of methyltriethoxysilane purified by vacuum distillation into the reaction kettle, heat the oil bath to 70°C, add 60 mol of deionized water according to the molar ratio of 1:2 and mix, stir the reaction and evaporate The liquid is extracted, and the viscosity of the evaporated liquid is monitored in real time with a rotational viscometer every 1 hour. When the viscosity reaches 300cP, the reaction is completed to obtain a silicone prepolymer;

[0029] (2) Dilute the silicone prepolymer and ethanol according to the mass ratio of 1:1 to prepare the coating sol;

[0030] (3) The coating sol was coated on the KDP substrate by the spin coating method, and the coating was homogenized for 1 min at a speed of 1000 r / min to obtain a film to be cured. ;

[0031] (4) heat-treat the film to be cured at 120° C. ...

Embodiment 2

[0034] The preparation method of the frequency doubling element matching film of the intense laser device in this embodiment includes the following steps:

[0035] (1) Add 30 mol of methyltriethoxysilane purified by vacuum distillation into the reaction kettle, heat the oil bath to 110°C, add 120 mol of deionized water according to the molar ratio of 1:4 and mix, stir the reaction and evaporate The liquid is extracted, and the viscosity of the evaporated liquid is monitored in real time with a rotational viscometer every 1 hour. When the viscosity reaches 700cP, the reaction is completed to obtain a silicone prepolymer;

[0036] (2) Dilute the silicone prepolymer and butanol according to the mass ratio of 1:3 to prepare the coating sol;

[0037] (3) The coating sol was coated on the KDP substrate by the spin coating method, and the coating was homogenized for 1 min at a speed of 400 r / min to obtain a film to be cured. ;

[0038] (4) heat-treat the film to be cured at 140° C....

Embodiment 3

[0041] The preparation method of the frequency doubling element matching film of the intense laser device in this embodiment includes the following steps:

[0042] (1) Add 30 mol of methyltriethoxysilane purified by vacuum distillation into the reaction kettle, heat the oil bath to 90°C, add 90 mol of deionized water according to the molar ratio of 1:3 and mix, stir the reaction and evaporate The liquid is extracted, and the viscosity of the evaporated liquid is monitored in real time with a rotational viscometer every 1 hour. When the viscosity reaches 1000cP, the reaction is completed to obtain a silicone prepolymer;

[0043] (2) Dilute the silicone prepolymer and acetone according to the mass ratio of 1:2 to prepare the coating sol;

[0044] (3) The coating sol was coated on the KDP substrate by the spin coating method, and the coating was homogenized for 1 min at a speed of 600 r / min to obtain a film to be cured. ;

[0045] (4) heat-treat the film to be cured at 130° C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical damage threshold | aaaaa | aaaaa |

| optical damage threshold | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com