Method and apparatus for producing and storing flowable slush, particularly for ice pigging

A technology of slurry and equipment, applied in the direction of cleaning methods and utensils, lighting and heating equipment, chemical instruments and methods, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Reference numerals appearing in more than one figure indicate like or corresponding parts in each of those figures.

[0026] In this specification, the solid fraction is considered to be the proportion of solid particles to the total volume of the slurry when measured by calorimetry. A simple approximation of the solid fraction can be obtained by the coffee pot method. Both methods are well known in the art and described eg in Ainslie (2010).

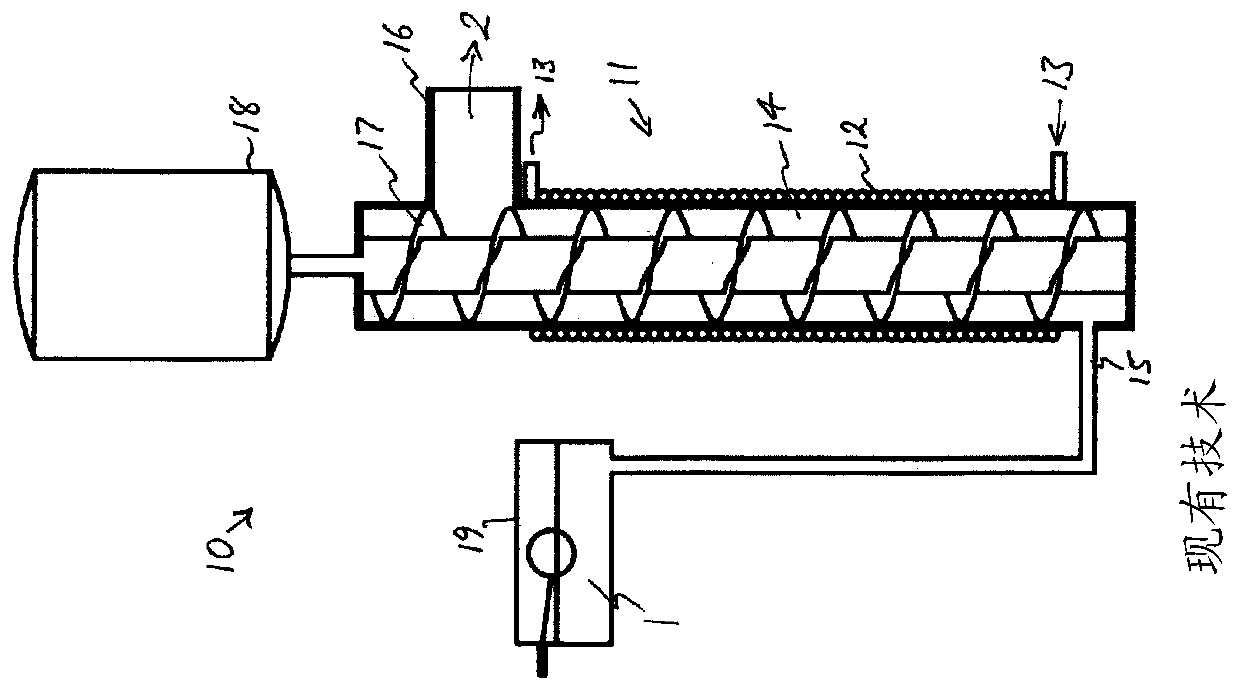

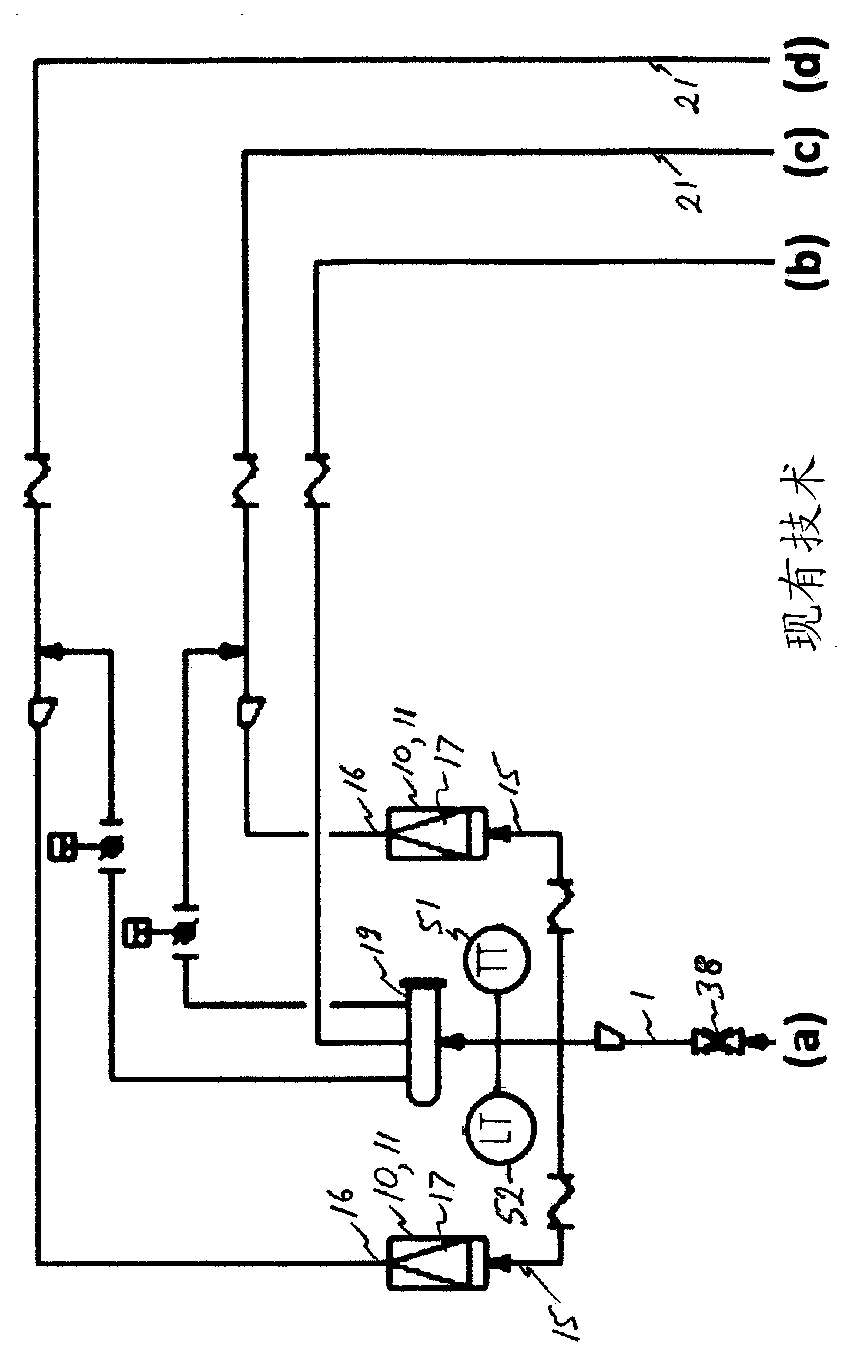

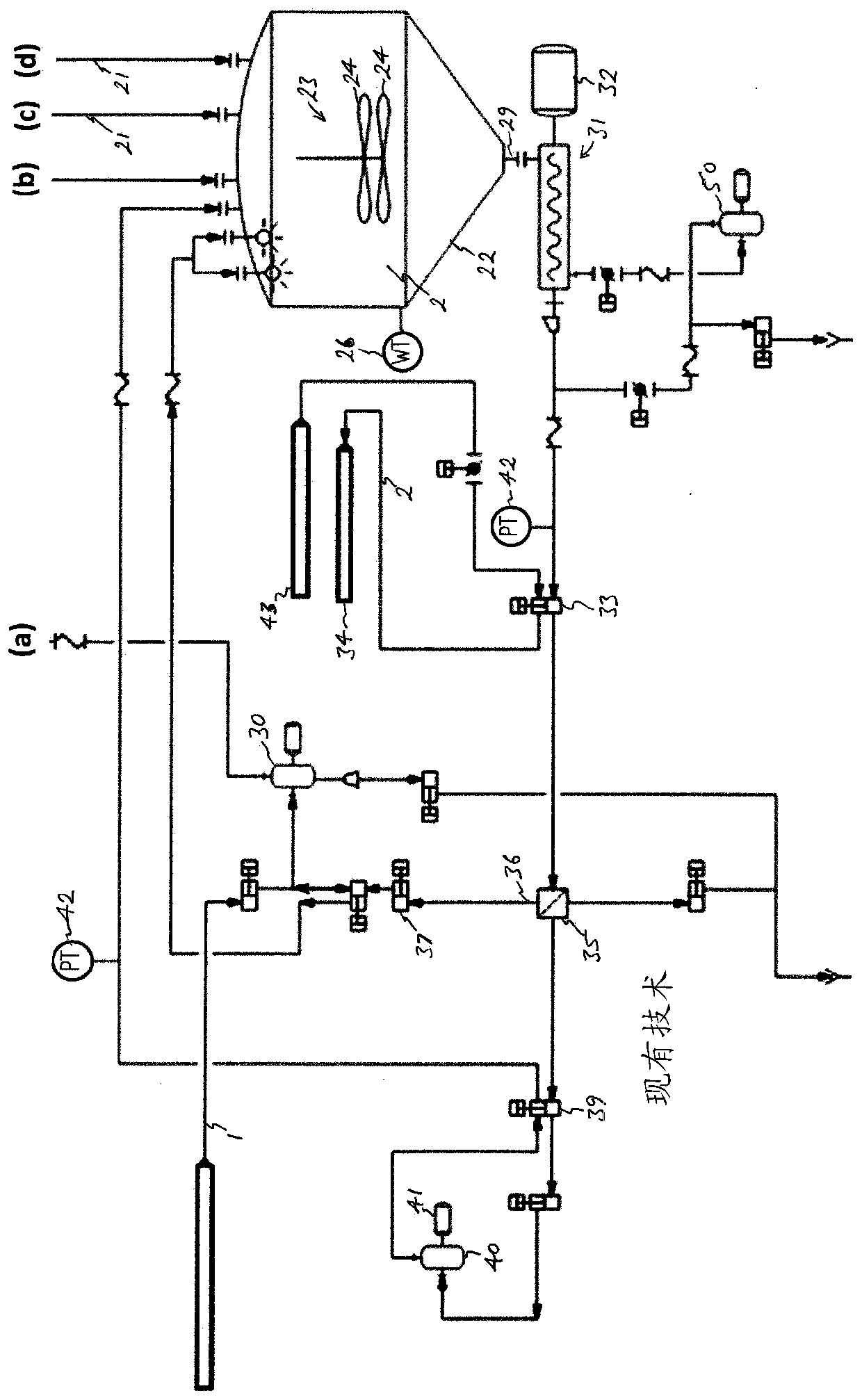

[0027] refer to image 3 , shows in simplified form an apparatus for producing a flowable slurry of frozen particles, the liquid flow paths are shown in solid lines and the slurry flow paths are shown in thick solid lines. The apparatus includes a control system 100 comprising processing and storage means known in the art, a selected one of signal and control inputs and outputs being indicated by dotted lines. For clarity, only some of the flow channels and signal or control lines are shown. Of course, it will be understood t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com