A kind of coating technology of naltrexone implant and its application

A technology for implants and naltrexone, which is applied to the drug coating process and its application fields, can solve problems such as affecting the integrity of the drug, adhesion and rupture on the surface of the coating, and achieve the effect of avoiding the problem of incomplete coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 naltrexone implant coating process

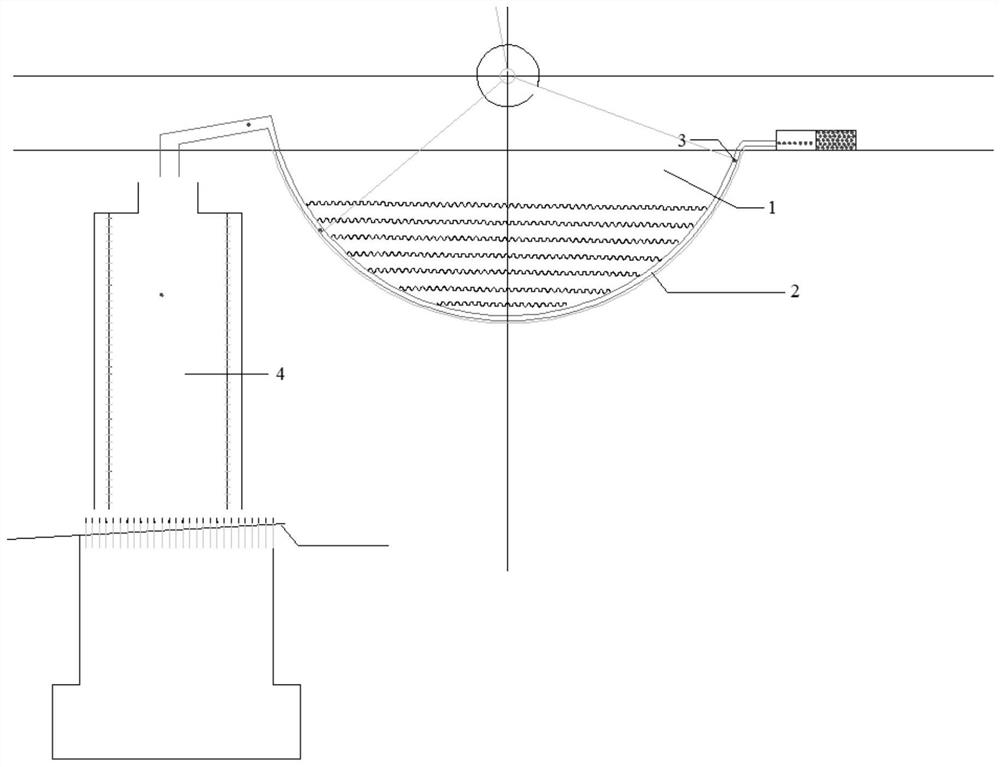

[0041] as attached figure 1 As shown, the coating process of naltrexone implants is specifically:

[0042] (1) Polylactic acid with a molecular weight of 60,000 is dissolved in methylene chloride to form a coating solution with a concentration of 6%, which is placed in the coating pool 1 for subsequent use;

[0043] (2) Push the naltrexone implant 3 into the liquid pool pipe 2 with evenly distributed small holes arranged inside the coated pool 1, and move the implant 3 from one end of the liquid pool pipe 2 to the other end by external force for encapsulation. film, the coating time is 30s, and the temperature is 37°C.

[0044] (3) The naltrexone implant 3 was transferred to the air-drying device 4, air-dried at 20° C. for 30 seconds, and then vacuum-dried at 40° C. for 48 hours.

[0045] Wherein, the aperture density of liquid pool pipeline 2 is 150 / 30cm tube length, and the pipeline diameter of liquid pool pipeline ...

Embodiment 2

[0047] Embodiment 2 naltrexone implant coating process

[0048] as attached figure 1 Shown, the coating process of naltrexone implant is:

[0049] (1) Polylactic acid with a molecular weight of 50,000 is dissolved in methylene chloride to form a coating solution with a concentration of 5%, which is placed in the coating pool 1 for subsequent use;

[0050] (2) Push the naltrexone implant 3 into the liquid pool pipe 2 with evenly distributed small holes arranged inside the coated pool 1, and move the implant 3 from one end of the liquid pool pipe 2 to the other end by external force for encapsulation. film, the coating time is 50s, and the temperature is 33°C.

[0051] (3) The naltrexone implant was transferred to the air-drying device 4, air-dried at 24° C. for 15 seconds, and then vacuum-dried at 30° C. for 50 hours.

[0052] Wherein, the small hole density of the liquid pool pipeline 2 is 100 / 30cm tube length, the diameter of the inlet of the liquid pool pipeline 2 is 0.5 mm...

Embodiment 3

[0054] Embodiment 3 naltrexone implant coating process

[0055] as attached figure 1 Shown, the coating process of naltrexone implant is:

[0056] (1) Polylactic acid with a molecular weight of 70,000 is dissolved in ethyl acetate to form a coating solution with a concentration of 7%, which is placed in the coating pool 1 for subsequent use;

[0057] (2) Push the naltrexone implant 3 into the liquid pool pipe 2 with evenly distributed small holes arranged inside the coated pool 1, and move the implant 3 from one end of the liquid pool pipe 2 to the other end by external force for encapsulation. film, the coating time is 15s, and the temperature is 40°C.

[0058] (3) The naltrexone implant 3 was transferred to the air-drying device 4, air-dried at 18° C. for 45 minutes, and then vacuum-dried at 50° C. for 50 hours.

[0059] Wherein, the aperture density of liquid pool pipeline 2 is 200 / 30cm pipe length, and the pipeline diameter of liquid pool pipeline 2 entrance and the pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com