Machining machine and machining method for manufacturing plastic steel tiles

A technology of processing machinery and plastic steel, which is applied in metal processing and other directions, can solve the problems of increased cutting error, large plastic steel tile size, and difficulty in repositioning, etc., and achieves the effects of uniform thrust, improved firmness, and improved moving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

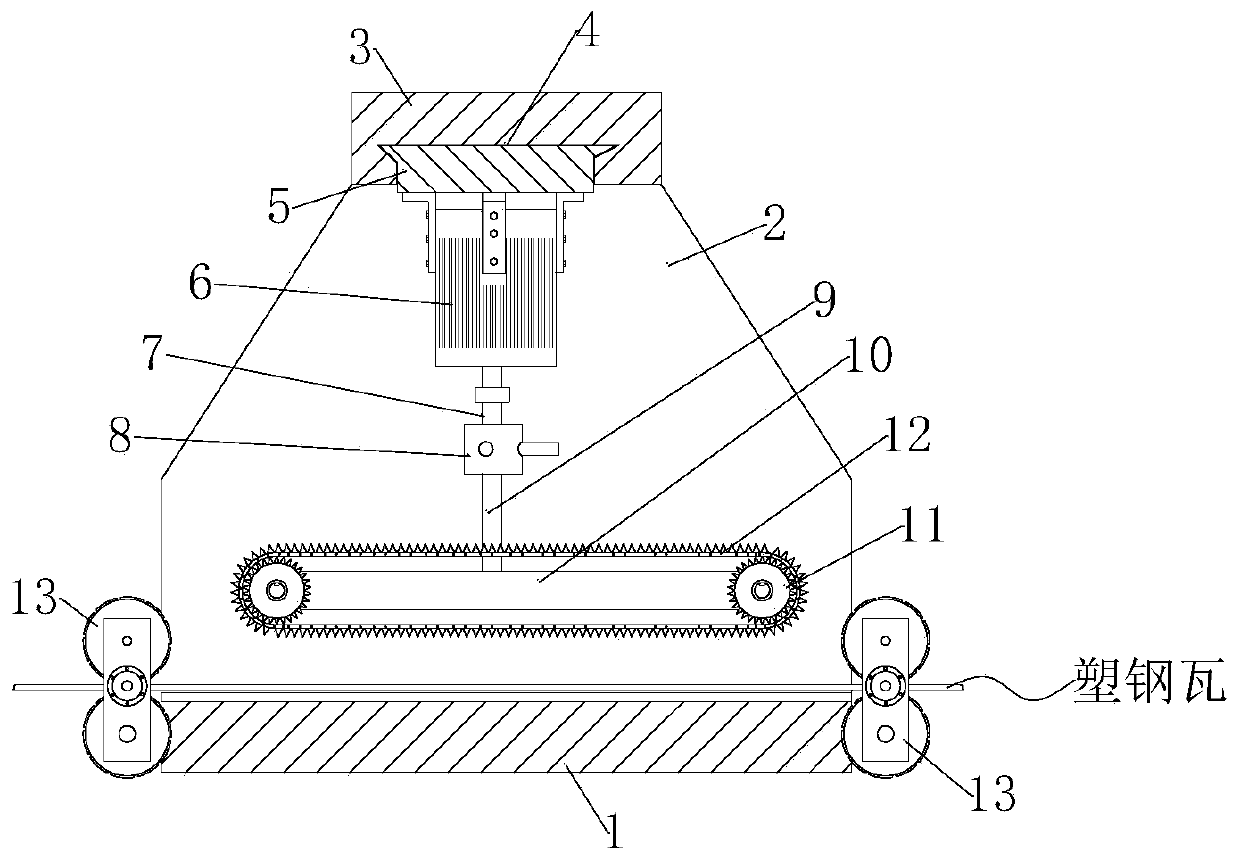

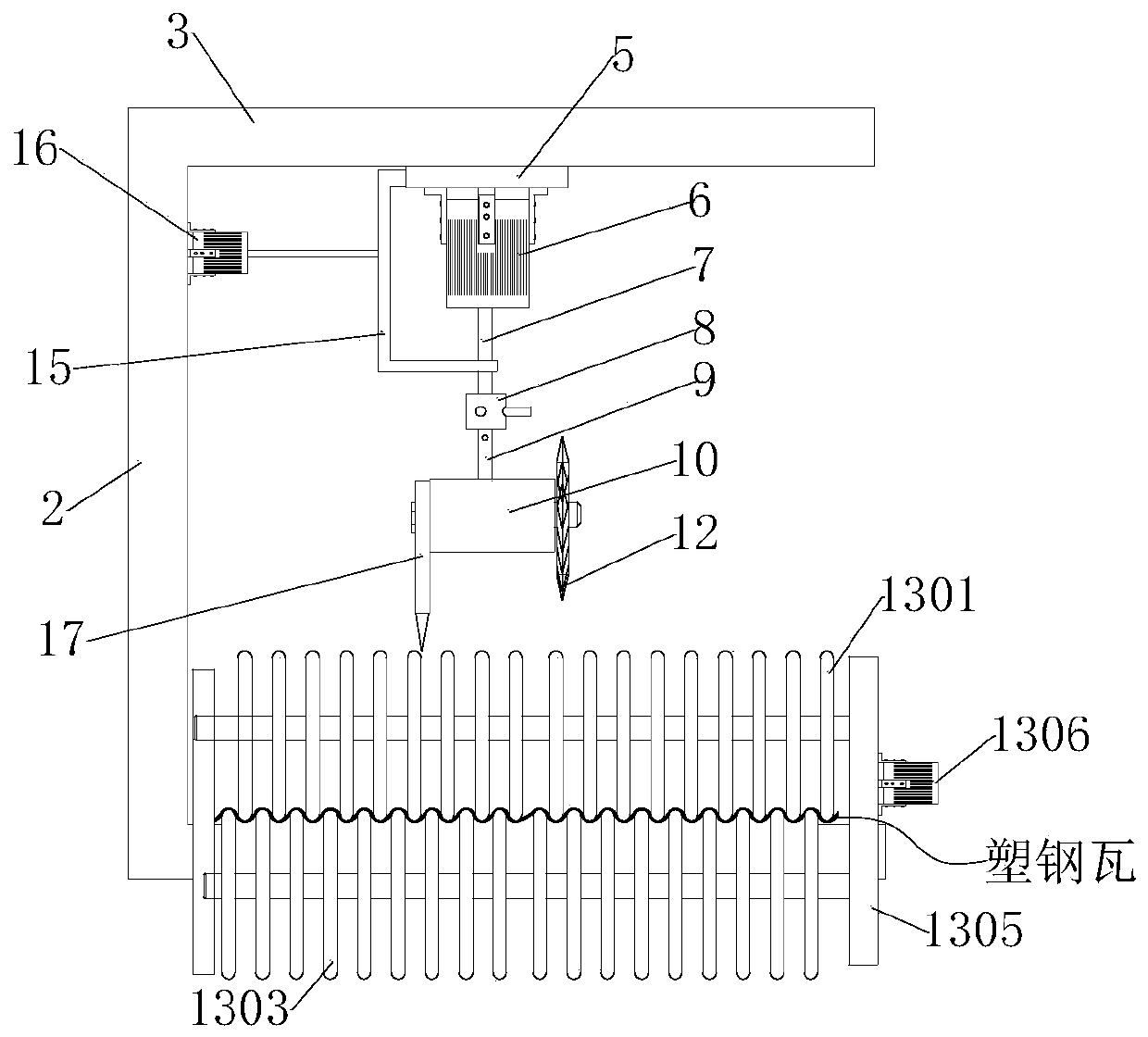

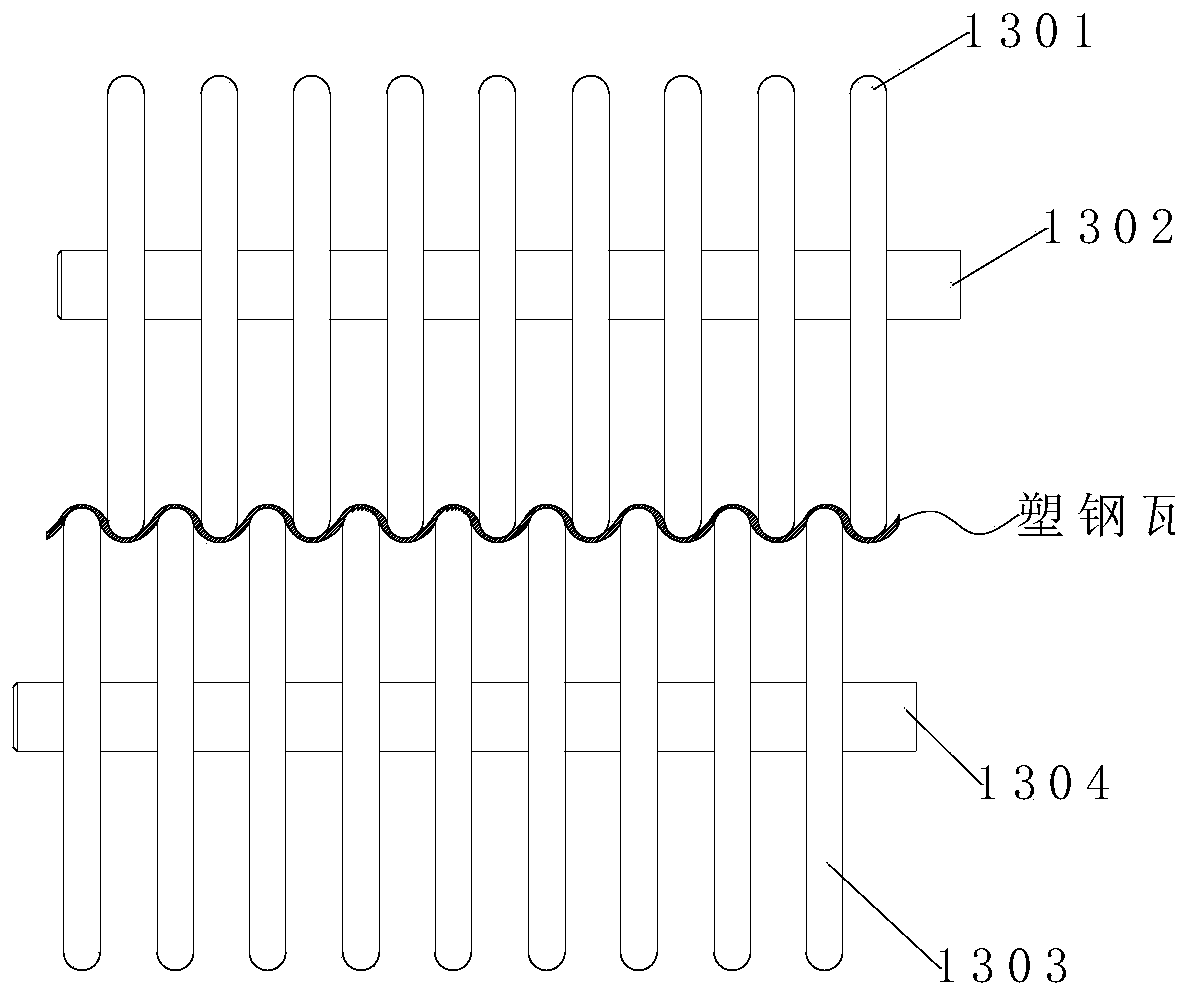

[0046] 1. Please refer to Figure 1-7 , is a schematic diagram of the overall structure of a plastic-steel tile manufacturing and processing machine, including a base 1. The base 1 is a square plate fixed horizontally on the ground. The top of the base 1 is fixed with a support plate 2 standing upright on the base 1. The support plate 2 has a trapezoidal structure. The top of the support plate 2 is fixed with a top support plate 3 arranged horizontally, and the bottom surface of the top support plate 3 is provided with a V-shaped structure chute 4, the chute 4 is perpendicular to the support plate 2, and the inside of the chute 4 A sliding seat 5 is embedded in a sliding fit, the bottom end of the sliding seat 5 is fixed with a hydraulic cylinder 6, the hydraulic cylinder 6 protrudes downwards from the piston rod 7, the bottom end of the piston rod 7 is fixed with an adjustment assembly 8, and the bottom of the adjustment assembly 8 A connecting rod 9 is installed at the end o...

Embodiment 2

[0062] see Figure 1-8 , is a schematic diagram of the overall structure of a plastic-steel tile manufacturing and processing machine and processing method. This embodiment has the same content as the above-mentioned embodiment 1, and the similarities will not be described in this embodiment. The specific differences are:

[0063] A plastic-steel tile manufacturing and processing machine provided by the present invention includes the following methods of use:

[0064] S1. Place the material, insert the plastic-steel tile from the transmission assembly 13, inserting refers to manually attaching the wave surface of the plastic-steel tile to the first transmission wheel 1301 and the second transmission wheel 1303 of the transmission assembly 13, through the transmission assembly 13 Move the plastic steel tile to the top of the base 1 at a constant speed;

[0065] S2. Longitudinal cutting of plastic-steel tiles. Slitting the plastic-steel tiles moved to the top of the base 1 in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com