A kind of 3D printing anti-grafting molding manufacturing method of mold for injection molding

A technology of 3D printing and manufacturing method, which is applied in the field of 3D printing reverse grafting molding of injection molds, which can solve problems such as complex structure, blockage, hidden dangers in use, etc., to achieve efficient and sufficient contact, ensure cooling effect, and ensure delivery speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

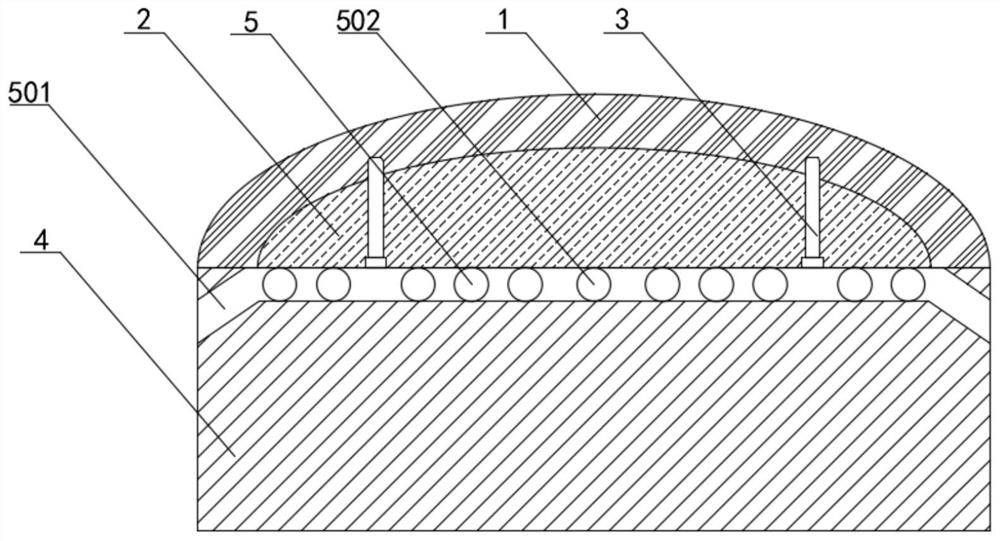

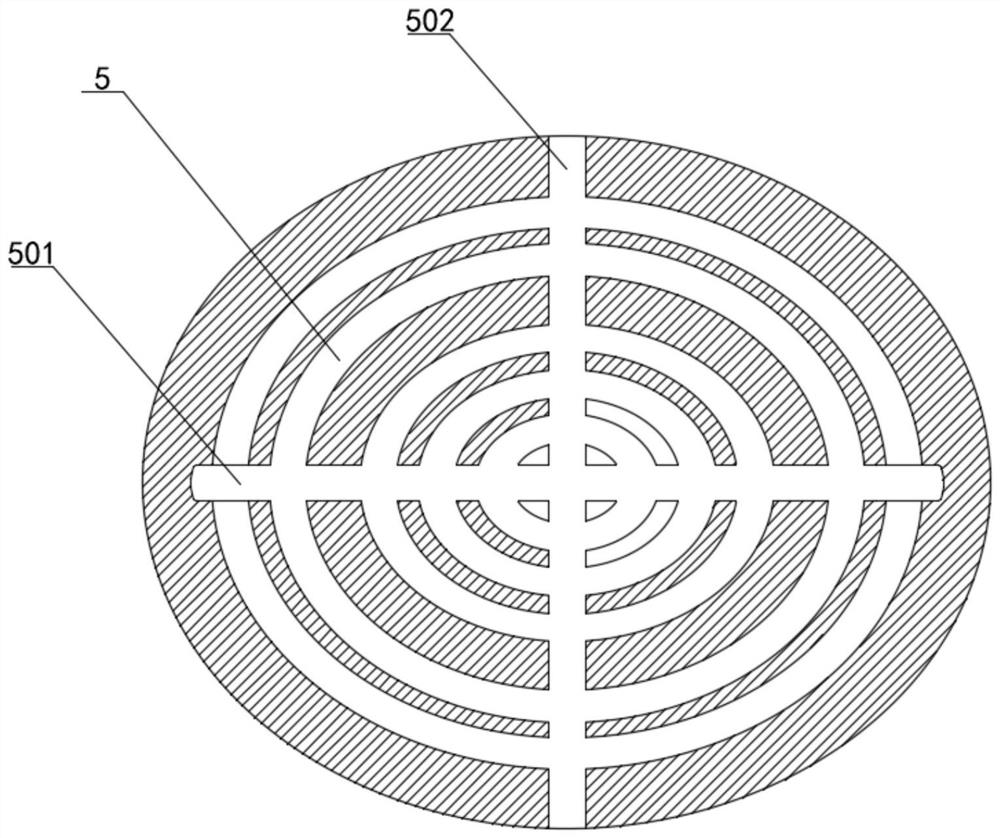

[0031] refer to figure 1 , a kind of 3D printing anti-grafting molding manufacturing method of mold for injection molding (the injection mold made by the present embodiment is the mouse upper cover production punch), and the specific molding steps are as follows:

[0032] 1) Forming of the mold end 1: the mold end 1 is formed by mold steel, and the end of the mold steel is processed into a convex arc shape according to the shape of the product through machining, and the bottom of the mold steel is processed into a The end of the mold has a consistent convex arc shape, and the end of the mold 1 is processed into a sheet shape suitable for the shape of the product;

[0033] 2) Processing of the cooling conduction pad 2: the cooling conduction pad 2 is made of beryllium copper material with excellent thermal conductivity, and the end of the cooling conduction pad 2 is processed into a convex arc shape consistent with the bottom of the mold steel, and The above-mentioned cooling ...

Embodiment 2

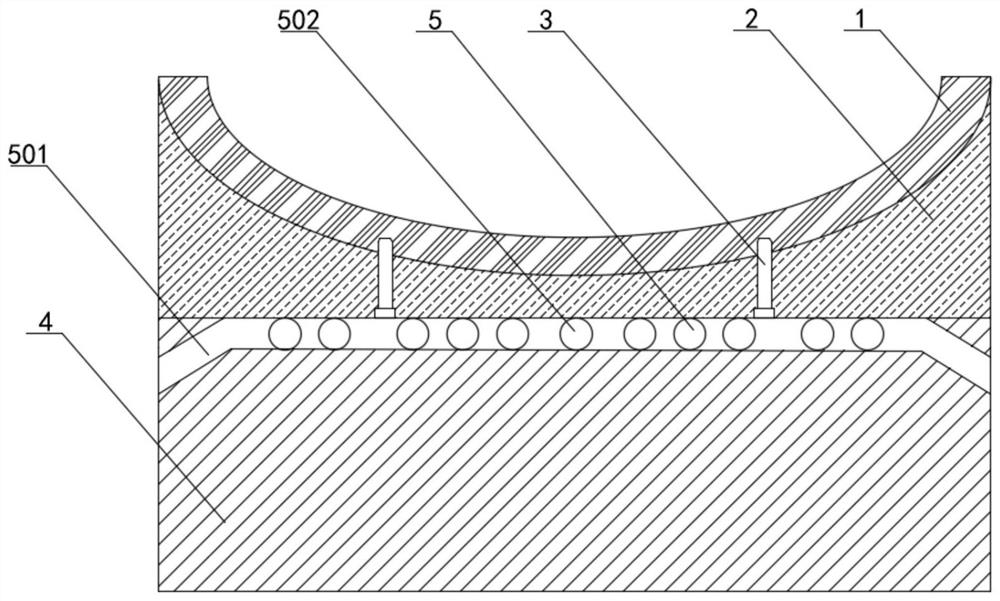

[0037] refer to figure 2 , a kind of 3D printing anti-grafting molding manufacturing method of mold for injection molding (the injection mold made in the present embodiment is the die for mouse upper cover production), and the specific molding steps are as follows:

[0038] 1) Forming of the mold end 1: the mold end 1 is formed by mold steel, and the end of the mold steel is processed into a concave arc shape according to the shape of the product through machining, and the bottom of the mold steel is processed into a The end of the mold has a consistent concave arc shape, and the end 1 of the mold is processed into a sheet shape suitable for the shape of the product;

[0039] 2) Processing of the cooling conduction pad 2: the cooling conduction pad 2 is made of beryllium copper material with excellent thermal conductivity, and the end of the cooling conduction pad 2 is processed into a concave arc shape consistent with the bottom of the mold steel, and The above-mentioned co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com