Solution for replacing silver plating in deposited nanostructure on surface of silicon matrix and use method thereof

A nanostructure, silver plating technology, applied in the direction of coating, liquid chemical plating, metal material coating technology, etc., can solve problems such as difficulties, and achieve the effect of convenient preparation, high purity, and simple solution components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh the reagent according to the following formula: AgNO 3 3.40 grams, 1.9 grams of NaF, and 80 grams of PVP (molecular weight 55000); earlier, the above reagents were dissolved with a small amount of water, and then mixed and diluted to 1 liter to obtain the silver coating solution of the present invention.

[0026] Wash the (001) oriented monocrystalline silicon wafer with sodium fluoride aqueous solution (concentration: 40 g / L, temperature: 50°C), and then wash with water to remove oxides on the surface of the silicon substrate;

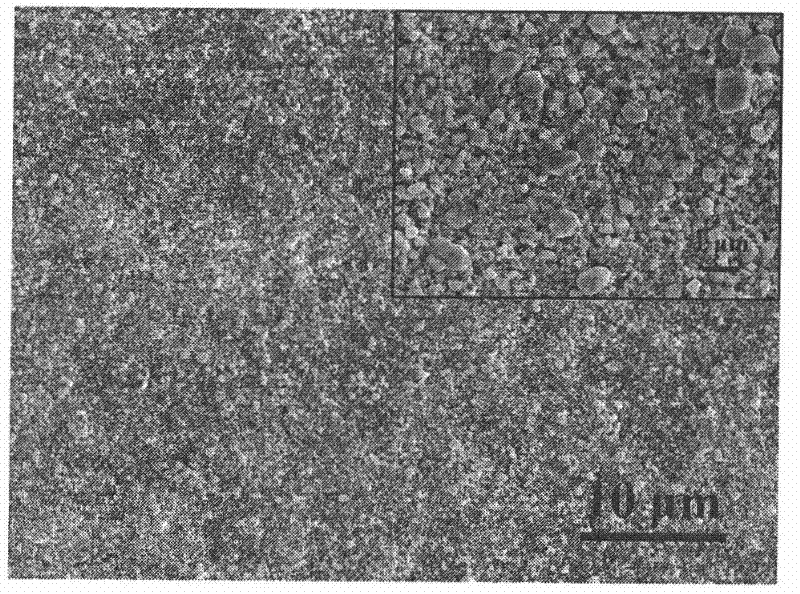

[0027] Immerse the cleaned monocrystalline silicon wafer in the silver coating solution prepared above, react at 50°C for 1.5 hours, then wash with water, and dry to obtain a silver coating composed of nanoparticles on the surface of the monocrystalline silicon wafer (see figure 1 ), the thickness of the coating is 5 μm, and the diameter of the nanoparticles is 100-200 nm.

Embodiment 2

[0029] Weigh the reagent according to the following formula: AgNO 3 3.40 grams, 1.9 grams of NaF, the above reagents were dissolved with a small amount of water respectively, and then mixed and diluted to 1 liter to obtain the silver coating solution of the present invention.

[0030] Wash the (001) oriented monocrystalline silicon wafer with sodium fluoride aqueous solution (concentration: 40 g / L, temperature: 50°C), and then wash with water to remove oxides on the surface of the silicon substrate;

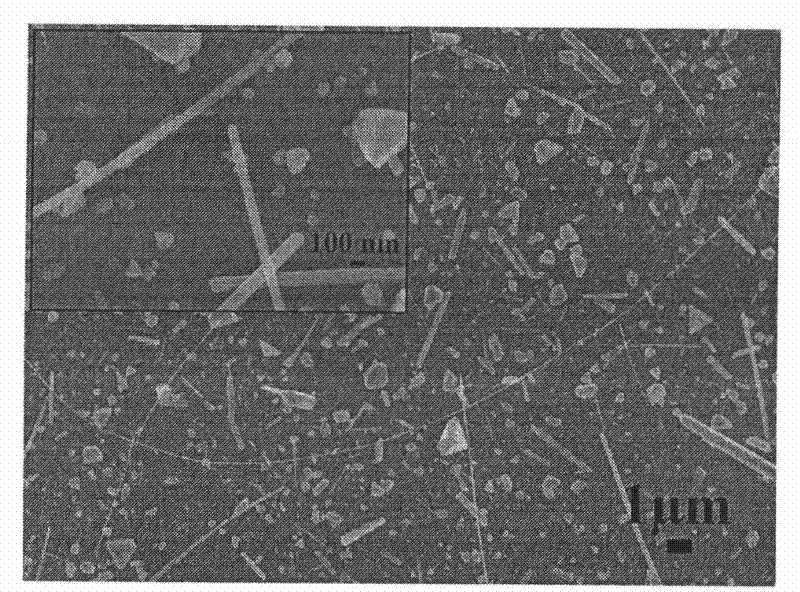

[0031] Dip the cleaned monocrystalline silicon wafer into the silver coating solution prepared above, react at 40°C for 3 hours, then wash with water and dry to obtain a mixed silver coating composed of nanowires and nanoparticles on the surface of the monocrystalline silicon wafer (See figure 2 ), the coating thickness is 80nm, the diameter of the silver nanowire is 40-100nm, and the length is 1-50μm; the diameter of the silver nano-particle is 10-50nm.

Embodiment 3

[0033] Weigh the reagent according to the following formula: AgNO 3 4.5 grams, NaF0.8 grams, PVP (molecular weight 55000) 0.5 grams, above-mentioned reagent is dissolved with a small amount of water respectively earlier, then mixed and diluted to 1 liter, promptly obtains the silver coating solution of the present invention.

[0034] Wash the (001) oriented monocrystalline silicon wafer with sodium fluoride aqueous solution (concentration: 40 g / L, temperature: 50°C), and then wash with water to remove oxides on the surface of the silicon substrate;

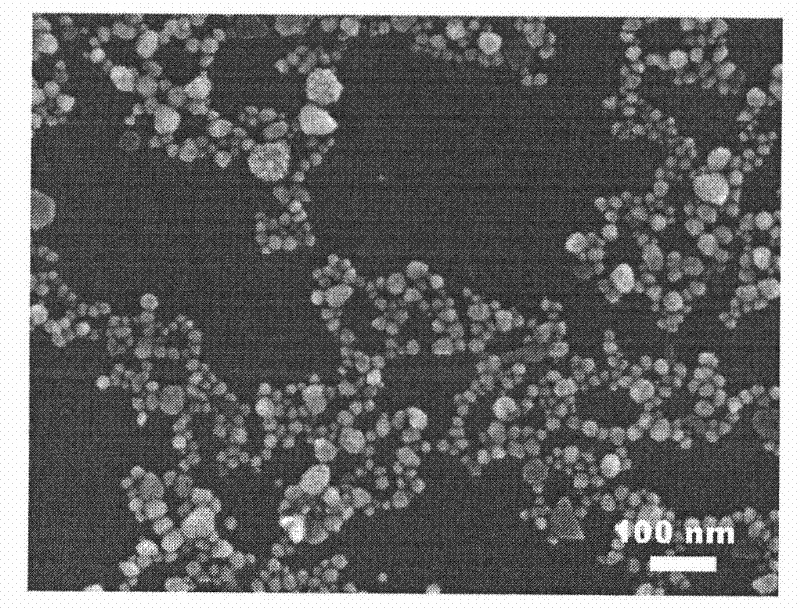

[0035] Dip the cleaned monocrystalline silicon wafer in the silver coating solution prepared above, react at 60°C for 1 hour, then wash with water, and dry to obtain a nanoparticle silver coating on the surface of the monocrystalline silicon wafer (see image 3 ), the thickness of the coating is 20nm, and the diameter of silver nanoparticles is about 10-30nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com