Sulfur wet forming granulation production system and production process

A technology of wet molding and production system, which is applied in the direction of sulfur compounds, sulfur preparation/purification, chemical instruments and methods, etc. It can solve the problems of increased production costs, no application value, increased internal stress of sulfur products, etc., and achieve low moisture content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

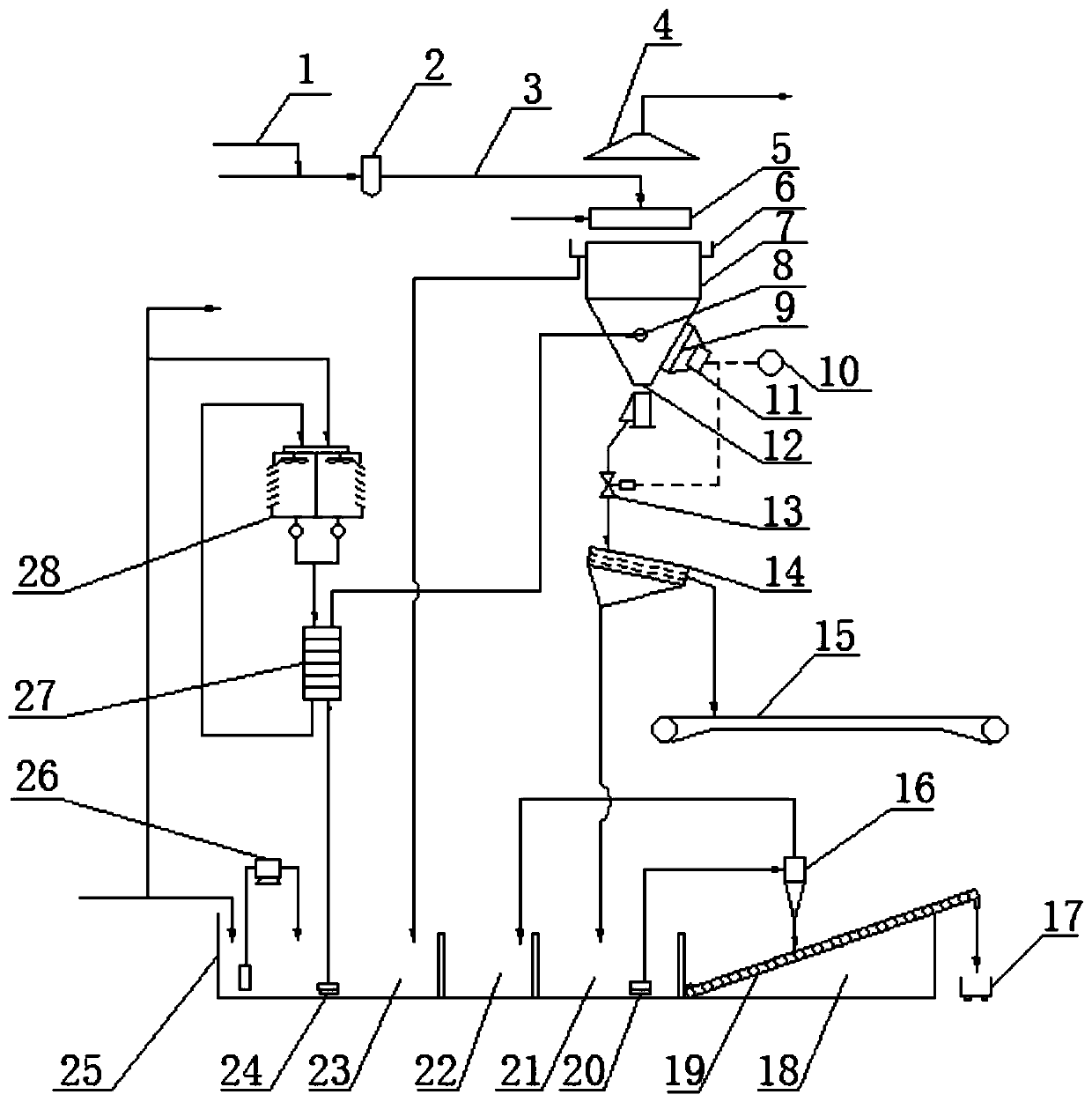

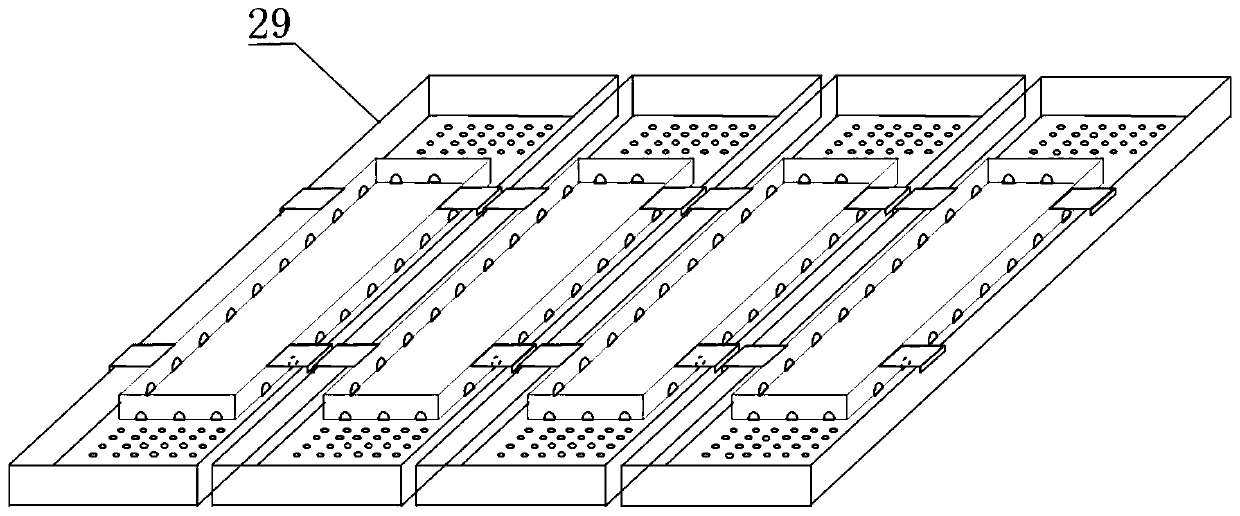

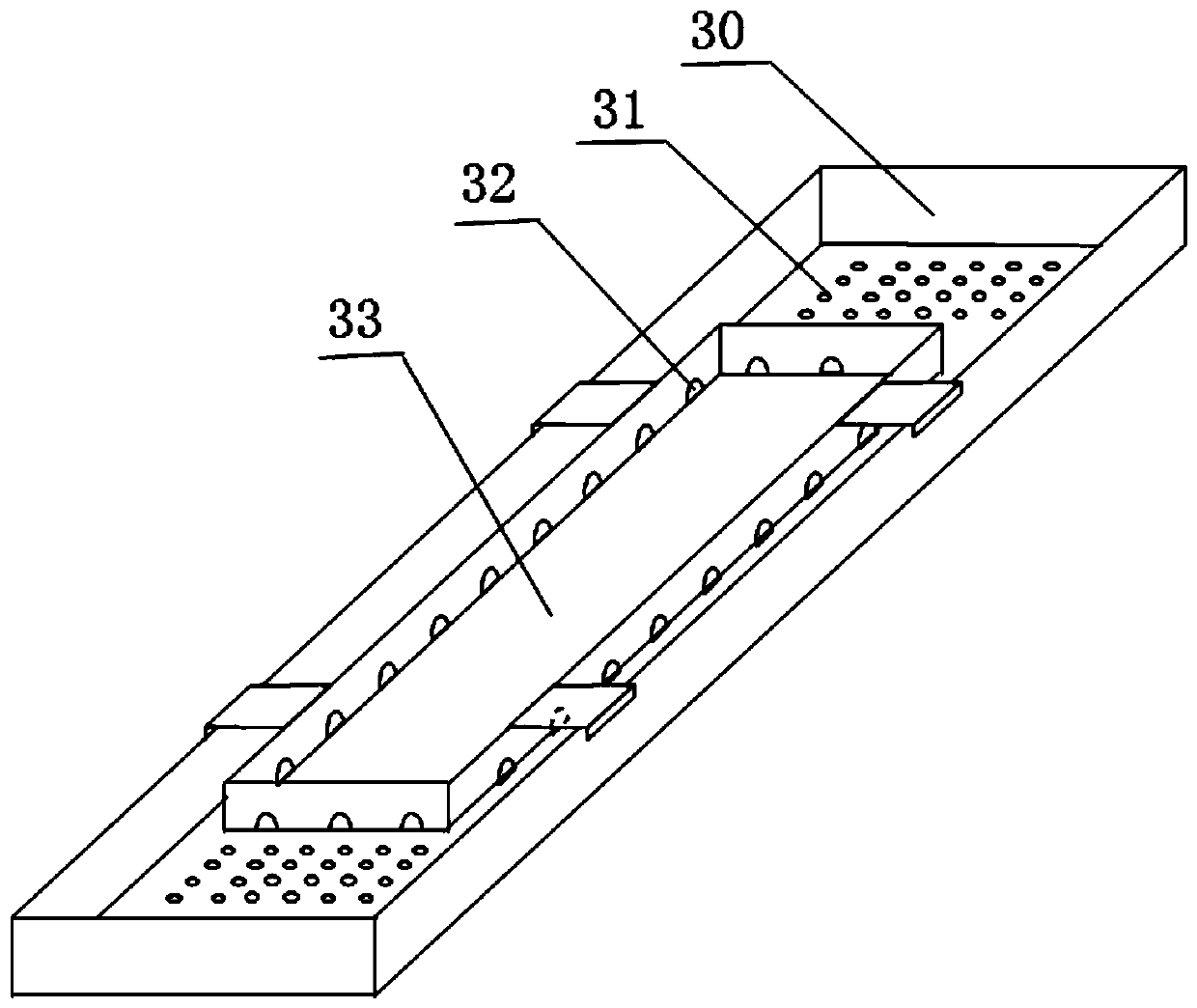

[0061] Such as Figure 1-4 As shown, the sulfur wet molding and granulation production system of the present invention includes a liquid sulfur filter 2, a liquid sulfur distributor 5, a granulation host 7, a product dehydration vibrating screen 14 and a product delivery device 15 arranged in sequence, and the liquid sulfur distribution The upper end of the device 5 is also provided with an exhaust device 4, and the lower end of the product dehydration vibrating screen 14 is also provided with a cooling water treatment integrated pool 25; And the clear water pool 23, the fine particle spiral lifting device 19 is arranged in the said concentration pool 18, and the pH monitoring device 26 is arranged in the said clear water pool 23.

[0062] The liquid sulfur filter 2 is installed on the liquid sulfur delivery pipe 3 connected with the heat preservation steam pipe 1 , and the end of the liquid sulfur delivery pipe 3 is arranged above the liquid flow distributor 5 .

[0063] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com