Polyurethane coating and preparation method therof

A polyurethane coating and isocyanate technology, applied in the field of materials, can solve the problems of sticking packaging and high emissions, and achieve the effects of fast reaction speed, uniform film formation and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

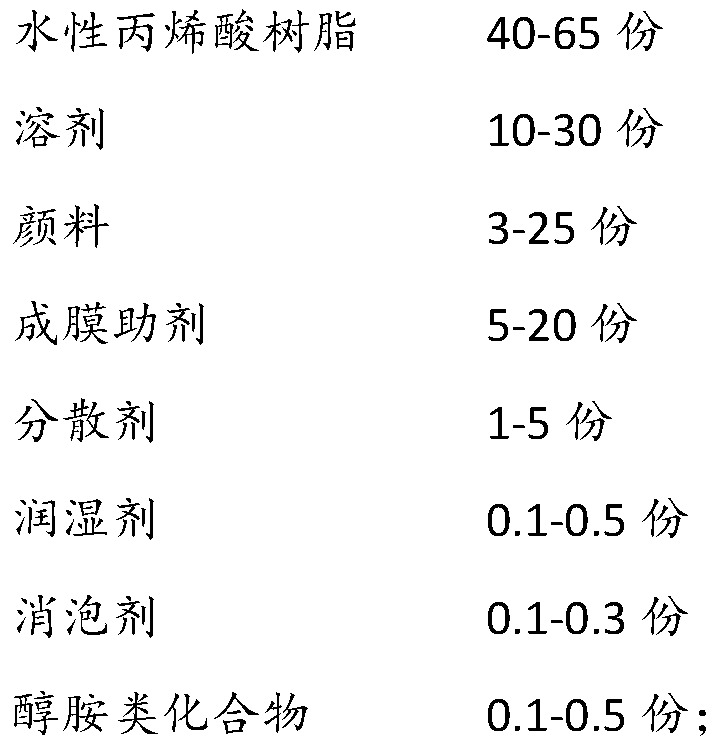

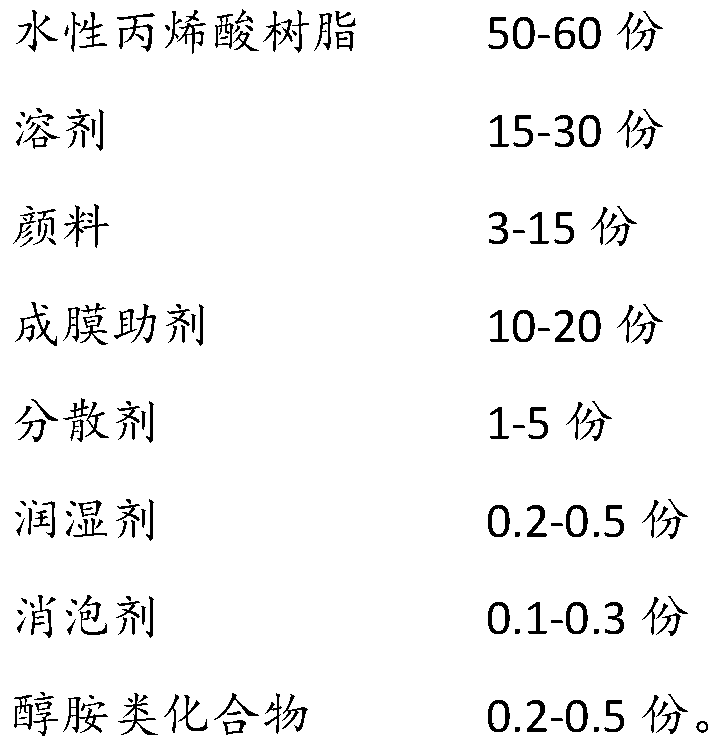

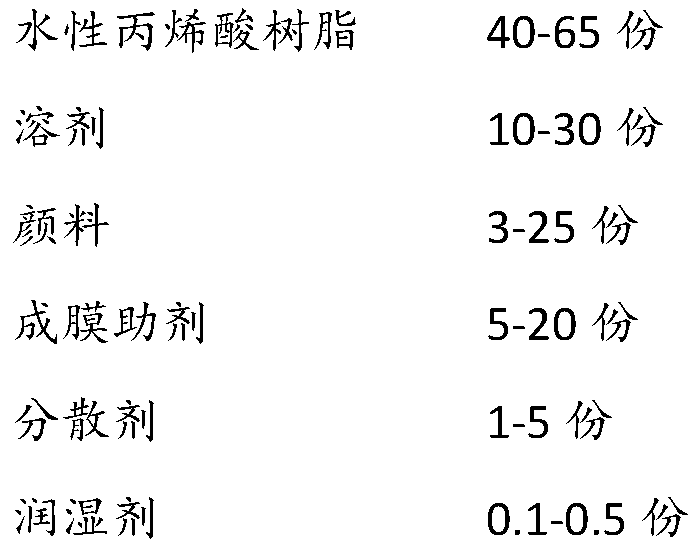

Method used

Image

Examples

Embodiment 1

[0031] Weigh 30 parts of DAS WD-551, 25 parts of DSM XK-540, 30 parts of deionized water, 3 parts of BYK2012, 0.2 parts of Evonik DEGO810, 5 parts of F5RK red pigment, stir and grind until The diameter is 10um, then add 0.3 parts of Evonik DEGO4100, 4 parts of dipropylene glycol methyl ether, 4 parts of alcohol ester dodecane, 4 parts of dibasic acid ester, 0.3 part of diethanolamine, stir well, and adjust the pH value in the range of 8.0-9.0. Pass through a 300-mesh filter to obtain component A; mix component A with 20 parts of Covestro XP2655 to obtain a polyurethane coating.

Embodiment 2

[0033] Weigh 55 parts of DIS WD-551, 20 parts of deionized water, 5 parts of Evonik DEGO755, 0.2 parts of BYK024, 10 parts of titanium dioxide, stir and grind until the particle size is 10um, and then add 0.3 parts of BYK BYK3440, 4 parts of dipropylene glycol methyl ether, 6 parts of alcohol ester dodeca, 4 parts of dibasic acid ester, 0.2 part of diethanolamine, stir evenly, adjust the pH value in the range of 7.5-8.5, and pass through a 300-mesh filter to obtain component A ; Mix component A with 20 parts of Covestro XP2655 to obtain a polyurethane coating.

Embodiment 3

[0035] Weigh 30 parts of DISMAN WD-551, 30 parts of DSM XK-540, 30 parts of deionized water, 3 parts of BYK2012, 0.2 parts of Evonik DEGO810, 15 parts of F5RK red pigment, stir and grind until granules The diameter is 10um, then add 0.3 parts of Evonik DEGO4100, 4 parts of dipropylene glycol methyl ether, 5 parts of alcohol ester dodecane, 4 parts of dibasic acid ester, 0.5 part of diethanolamine, stir well, and adjust the pH value in the range of 8.0-9.5. Pass through a 300-mesh filter to obtain component A; mix component A with 20 parts of Covestro XP2655 to obtain a polyurethane coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com