A secondary biomass conversion process

A biomass and process technology, applied in the field of biomass secondary conversion process, can solve the problems of low calorific value of oil products and large amount of waste water, and achieve the effects of simple process, increased fluidity, and increased compression pressure and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

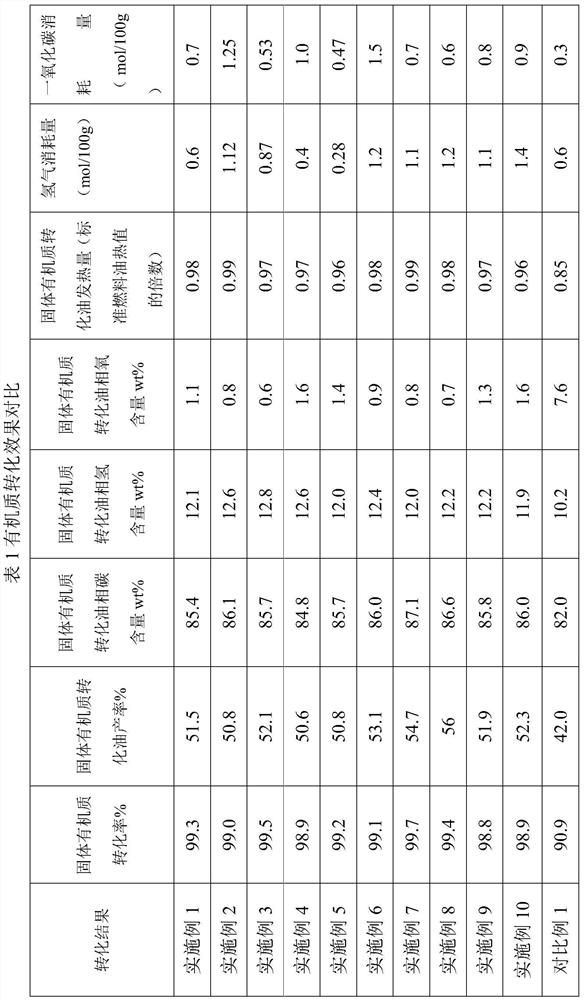

Examples

Embodiment 1

[0072] This embodiment provides a biomass secondary conversion process, comprising the following steps:

[0073] Preparation of biomass slurry:

[0074] collecting corn stalks, the water content of which is 5-20wt%, and then pulverizing them to a particle size of 0.2 μm-5 cm by using an ultrafine pulverizer;

[0075] Compress the crushed straw with a plodder, the compression pressure is 2.5MPa, the compression temperature is 45°C, and compressed to a true density of 1.0kg / m 3 ;

[0076] The compressed and molded straw was pulverized again with a jet mill, passed through a 100-mesh sieve to obtain straw powder, and 40 kg of straw powder was weighed and mixed with a catalyst to obtain a mixed powder;

[0077] 80kg of waste lubricating oil, mixed powder, and 4kg of water were mixed, and a colloid mill was used for grinding and pulping. The grinding and pulping time was 15 minutes to obtain a biomass slurry.

[0078] The catalyst added in the slurry is an iron-based catalyst w...

Embodiment 2

[0090] This embodiment provides a biomass secondary conversion process, comprising the following steps:

[0091] Preparation of biomass slurry:

[0092] Collecting wheat straw, the water content of which is 10-20wt%, and then pulverizing it to a particle size of 0.2μm-5cm by using an ultrafine pulverizer;

[0093] Compress the crushed straw with a plodder, the compression pressure is 0.5MPa, the compression temperature is 60°C, and compressed to a true density of 0.75kg / m 3 ;

[0094] The compressed and molded straw is pulverized again with a jet mill, and passed through an 80-mesh sieve to obtain straw powder;

[0095] 100kg of washing oil was mixed with 100kg of straw powder and 3kg of water, and a colloid mill was used for grinding and pulping. The grinding and pulping time was 8 minutes to obtain biomass slurry.

[0096] The catalyst added in the slurry is an iron-based catalyst with a content of 1 wt%, and the average particle diameter of the added iron-based catalyst...

Embodiment 3

[0110] This embodiment provides a biomass secondary conversion process, comprising the following steps:

[0111] Preparation of biomass slurry:

[0112] Collect red algae, air-dry until its water content is lower than 20wt%, and crush to a particle size of 0.2 μm-5cm;

[0113] Compress the pulverized red algae into a tablet press with a compression pressure of 3MPa, a compression temperature of 40°C, and compress to a true density of 0.95kg / m 3 ;

[0114] The compressed red algae is pulverized again with a jet mill, and passed through a 100-mesh sieve to obtain red algae powder;

[0115] Get 40kg pulverized red algae powder and mix with 50kg waste engine oil and 4kg water, grind and make slurry for 12min to obtain biomass slurry.

[0116] The catalyst added in the slurry is an iron-based catalyst with a content of 1 wt%, and the average particle diameter of the added iron-based catalyst is 10 μm.

[0117] Iron catalyst:

[0118] The iron-based catalyst is amorphous FeO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com