A solid biomass conversion process

A solid biomass, biomass technology, applied in the direction of biofuels, solid fuels, waste fuels, etc., can solve the problems of large amount of waste water and low calorific value of oil products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

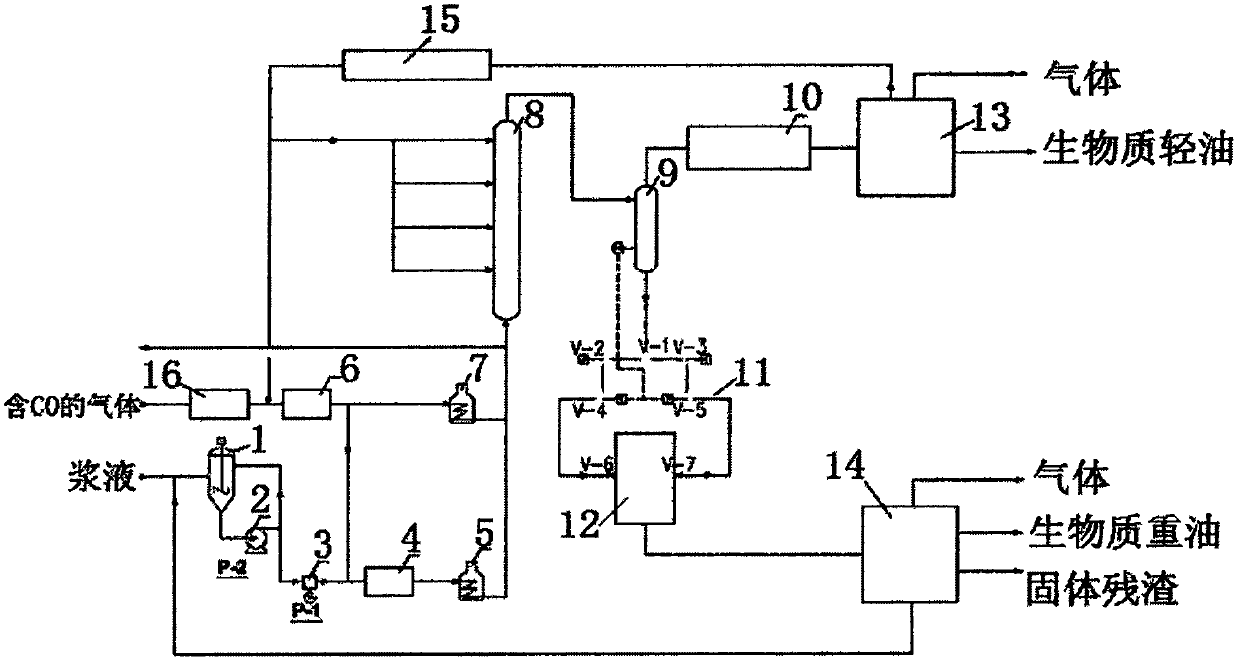

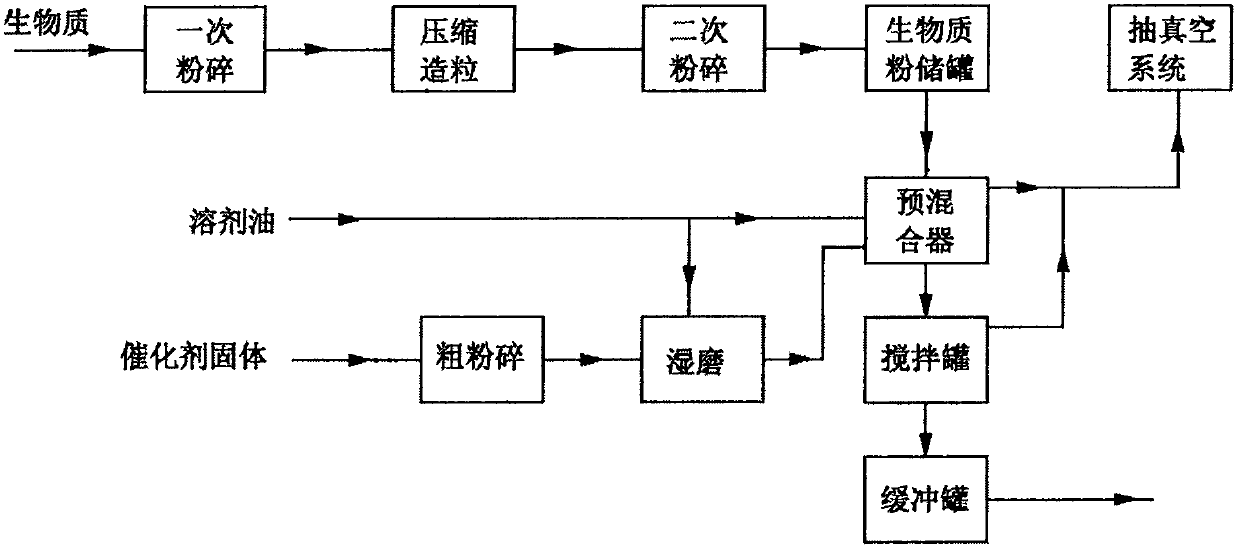

[0081] This embodiment provides a solid biomass conversion process, such as figure 1 and figure 2 shown, including the following steps:

[0082] Biomass pretreatment:

[0083] Rice straw and reed straw are used as solid biomass, and the rice straw and reed straw are sent to the ultrafine pulverizer for primary crushing. The average particle size after primary crushing is 100 μm, and then the primary crushed rice straw and reed straw are sent to the Compressed in a briquetting machine, extruded to a diameter of 8mm, a length of 25mm, and an apparent density of not less than 0.4g / cm 3 , the water content is not greater than 15%, and then secondary pulverization is carried out by a roller mill. After secondary pulverization, biomass powder with an average particle size of 3mm is obtained, which is stored in a biomass powder storage tank for standby;

[0084] Catalyst and its pretreatment:

[0085] 1. Catalyst: The catalyst is the waste agent of the desulfurizer with FeOO...

Embodiment 2

[0099] This embodiment provides a solid biomass conversion process, comprising the following steps:

[0100] Biomass pretreatment:

[0101]Wheat straw and corn straw are used as solid biomass, and the wheat straw and corn straw are sent to the ultrafine pulverizer for primary crushing. The average particle size after primary crushing is 5cm, and then the primary crushed wheat straw and corn straw are sent to Compressed in a briquetting machine, extruded to a diameter of 2mm, a length of 50mm, and an apparent density of not less than 0.4g / cm 3 , the water content is not greater than 15%, and then secondary pulverization is carried out by a roller mill. After secondary pulverization, biomass powder with an average particle size of 5mm is obtained, which is stored in a biomass powder storage tank for standby;

[0102] Catalyst and its pretreatment:

[0103] 1. Catalyst: The catalyst is a waste agent of a desulfurizer with iron oxide as an active component, wherein, in the d...

Embodiment 3

[0120] This embodiment provides a solid biomass conversion process, comprising the following steps:

[0121] Biomass pretreatment:

[0122] Cotton stalks are used as solid biomass, and the cotton stalks are sent to a jet mill for primary crushing. The average particle size after primary crushing is 1cm, and then the primary crushed cotton stalks are sent to a briquetting machine for compression and extrusion. To its diameter of 10mm, length of 3mm, apparent density not less than 0.4g / cm 3 , the moisture content is not greater than 15%, and then secondary pulverization is carried out by a roller mill. After secondary pulverization, biomass powder with an average particle size of 200 μm is obtained, which is stored in a biomass powder storage tank for standby;

[0123] Catalyst and its pretreatment:

[0124] 1. Catalyst: the catalyst is amorphous FeOOH; add sulfur: add solid sulfur powder to the above catalyst until the molar ratio of iron and sulfur is 1:2, so as to ensur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com