A two-stage conversion and refining process of biomass

A biomass and process technology, applied in the fields of chemical industry, biomass utilization, and energy, can solve the problems of low yield of liquefied oil, large amount of waste water, and low calorific value of oil products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

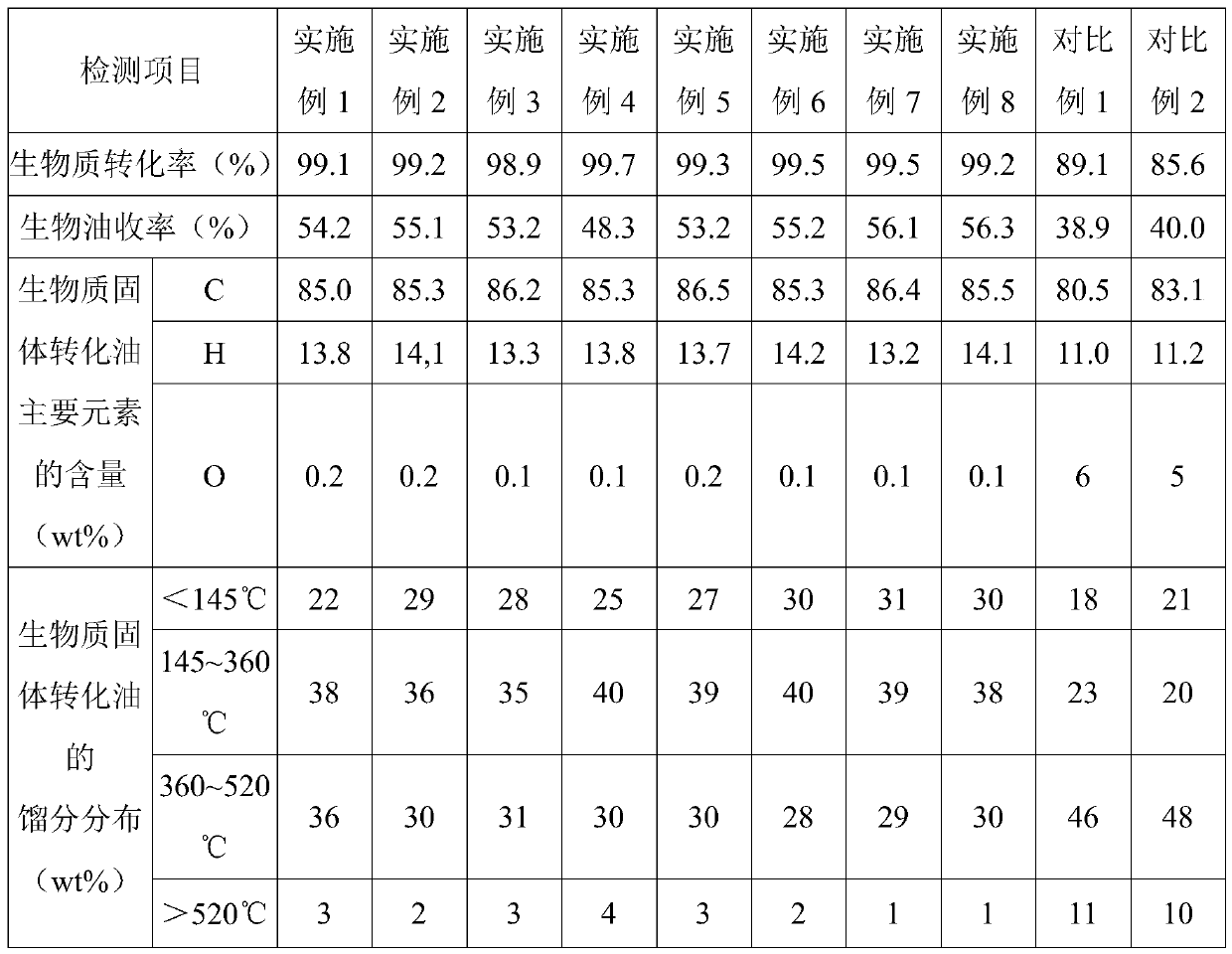

Examples

Embodiment 1

[0102] This embodiment provides a two-stage conversion and purification process for biomass, which includes the following steps:

[0103] Iron-based catalyst:

[0104] The iron-based catalyst is a waste agent of a desulfurizer with iron oxide as the active component, wherein, in the desulfurizer with iron oxide as the active component, calcium bicarbonate is 10g, basic copper carbonate is 12g, and γ-Fe 2 O 3 18g, MnO 2 8g, NiO is 5g;

[0105] The desulfurization process of the desulfurizer with iron oxide as the active component is summarized as follows:

[0106] 1) Collect the tail gas produced by the fixed bed hydrogenation catalysis of medium and low temperature coal tar;

[0107] 2) The desulfurizing agent of this embodiment is made into columnar catalyst particles with a diameter of 1 mm and a length of 15 mm, and filling them in the desulfurization tower to form a desulfurization layer;

[0108] 3) Reduce the above exhaust gas to 2000h -1 The space velocity through the desulfuriza...

Embodiment 2

[0127] This embodiment provides a two-stage conversion and purification process for biomass, which includes the following steps:

[0128] Iron-based catalyst:

[0129] The iron-based catalyst is amorphous FeOOH; adding sulfur: the above-mentioned iron-based catalyst is mixed with solid sulfur powder so that the molar ratio of iron to sulfur is 1:2, so as to ensure that the molar ratio of iron to sulfur in the reaction system is 1:2;

[0130] Preparation of slurry:

[0131] (1) Collect corn stalks with a moisture content of 5-20wt%, and then use an ultrafine pulverizer to crush them to a particle size of 0.2-5 cm;

[0132] (2) Compress and shape the stalks crushed in step (1) with a plodder. The compression pressure is 2.5MPa, the compression temperature is 45°C, and the true density is 1.0kg / m. 3 ;

[0133] (3) The straw after compression molding in step (2) is pulverized again with a jet mill to a particle size of 0.1-500 microns to obtain straw powder;

[0134] (4) Mix 80 kg of waste ...

Embodiment 3

[0147] This embodiment provides a two-stage conversion and purification process for biomass, including the following steps:

[0148] Iron-based catalyst:

[0149] The iron-based catalyst is the regeneration of the waste agent of the desulfurizer with iron oxyhydroxide as the active component. Among them, based on the total mass of the desulfurizer with iron oxyhydroxide as the active component, the α-FeOOH is 30g, and the amorphous oxyhydroxide is oxidized Iron is 20g, potassium oxide is 8g, and binder kaolin is 10g;

[0150] The above-mentioned desulfurizer with iron oxyhydroxide as the active component is used in the desulfurization process of the tail gas produced after the hydro-upgrading of coal tar at medium and low temperature in industry as follows:

[0151] 1) Collect the tail gas produced by the fixed bed hydrogenation catalysis of medium and low temperature coal tar;

[0152] 2) The desulfurizer of this embodiment is made into columnar catalyst particles with a diameter of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com