Method for carrying out extraction separation on zirconium and hafnium by bisphosphate extraction agent

An extraction agent, bisphosphoric acid technology, applied in the field of extraction and separation of zirconium and hafnium with new bisphosphoric acid extraction agent, can solve the problems of low extraction rate of zirconium and hafnium, poor separation effect, environmental pollution, etc., achieve high extraction rate, low pollution, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

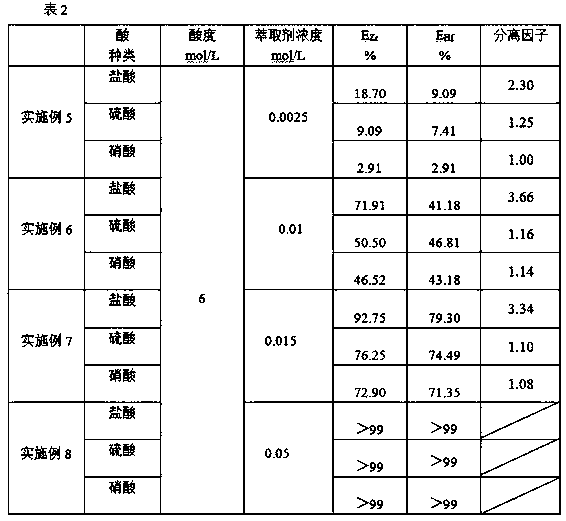

Embodiment 1

[0024] Prepare solutions with zirconium and hafnium ion concentrations of 1 g / L and 0.02 g / L, and acidity of 0.01 mol / L as the water phase. With chloroform as the diluent, 0.005 mol / L N,N-n-octylamine bis (methylene phenyl hypophosphorous acid) was prepared as the organic phase.

[0025] The organic phase and the aqueous phase were mixed in a volume ratio of 1:1, the extraction temperature was controlled to 20°C, and after shaking for 5 minutes, the phase was separated by a centrifuge. The concentration of metal ions in the water phase is detected, and the organic phase is stripped with deionized water at 30°C. The stripping rate is as high as 99%.

[0026] The specific experimental parameters and extraction and separation performance are shown in Table 1.

Embodiment 2

[0028] The solutions of zirconium and hafnium ion concentrations of 1 g / L and 0.02 g / L and acidity of 1 mol / L were prepared as the water phase. With chloroform as the diluent, 0.005 mol / L N,N-n-octylamine bis(methylene phenyl hypophosphorous acid) was prepared as the organic phase.

[0029] The organic phase and the aqueous phase are mixed in a volume ratio of 1:1, the extraction temperature is controlled at 30°C, and after shaking for half an hour, the phase is separated by a centrifuge. Detect the concentration of metal ions in the water phase and use deionized water to strip the organic phase at 30°C. The stripping rate is as high as 99%.

[0030] See Table 1 for specific experimental parameters and extraction and separation performance.

Embodiment 3

[0032] Prepare solutions with zirconium and hafnium ion concentrations of 1 g / L and 0.02 g / L, and acidity of 3 mol / L as the water phase. With chloroform as the diluent, 0.005 mol / L N,N-n-octylamine bis (methylene phenyl hypophosphorous acid) was prepared as the organic phase.

[0033] The organic phase and the aqueous phase were mixed in a volume ratio of 1:1, the extraction temperature was controlled to 50°C, and after shaking for one hour, the phase was separated by a centrifuge. Detect the concentration of metal ions in the water phase and use deionized water to strip the organic phase at 30°C. The stripping rate is as high as 99%.

[0034] The specific experimental parameters and extraction and separation performance are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com